Contents

- Turnkey PCB Assembly Key Benefits at a Glance

- What Does Turnkey PCB Assembly Include?

- Turnkey PCB Assembly vs Traditional PCB Assembly

- The Complete Turnkey PCB Assembly Process

- Key Benefits of Turnkey PCB Assembly

- How Turnkey PCB Assembly Reduces Costs and Lead Times?

- Quality Control in Turnkey PCB Assembly

- Choosing the Right Turnkey PCB Assembly Partner

- Common Challenges and How to Avoid Them

- Frequently Asked Questions About Turnkey PCB Assembly

- Conclusion

| Benefit | Impact | Why It Matters |

|---|---|---|

| Lead Time Reduction | 30-40% faster delivery | Faster time-to-market |

| Cost Savings | 10-20% total cost reduction | Lower overhead and admin costs |

| Quality Control | Lower defect rates | Integrated testing processes |

| Project Management | Single point of contact | Simplified coordination |

Turnkey PCB assembly is a complete manufacturing solution where one provider handles everything from design to delivery. Instead of managing multiple vendors, you work with a single company that takes care of component sourcing, PCB fabrication, assembly, testing, and shipping. This approach can reduce your project timeline by up to 40% while cutting costs significantly.

Professional PCB design and layout services ensure optimal performance

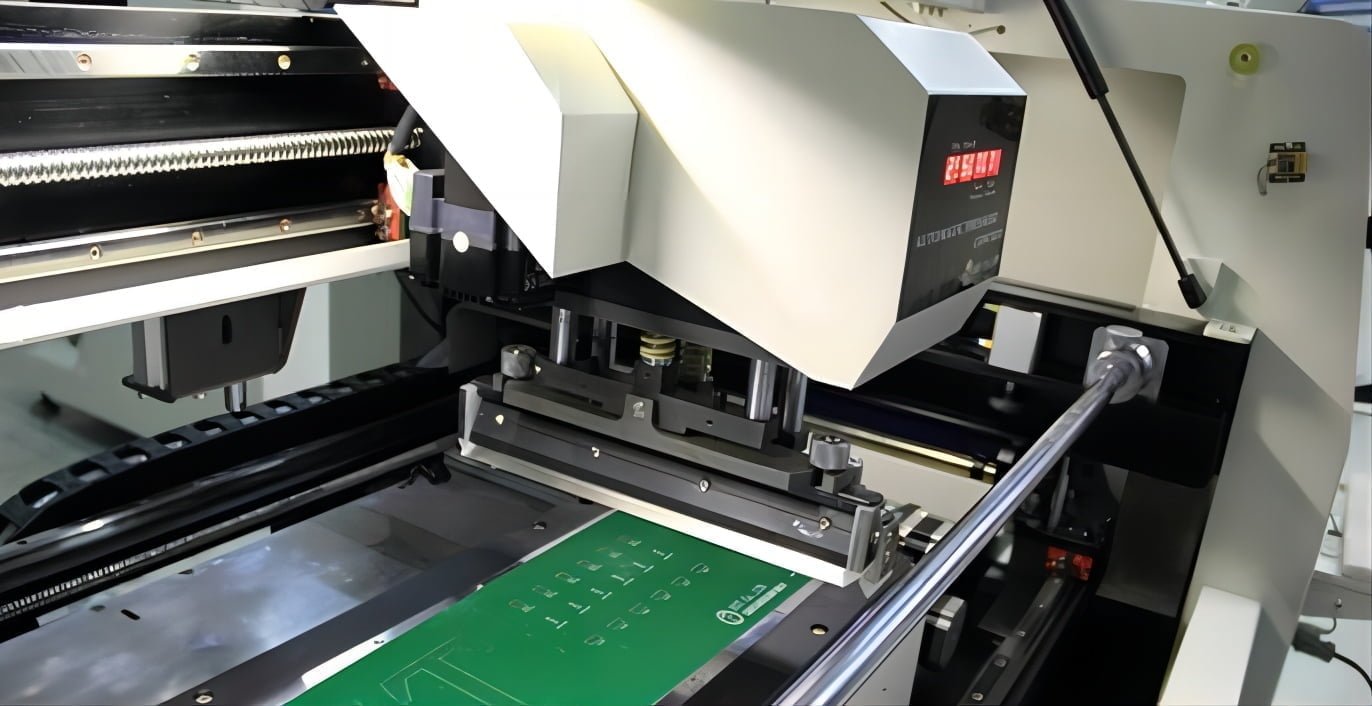

Advanced SMT assembly lines handle components as small as 01005

Comprehensive testing ensures every PCB meets quality standards

What Does Turnkey PCB Assembly Include?

A complete turnkey PCB assembly service includes several key components that work together seamlessly. Moreover, this comprehensive approach eliminates the need to coordinate with multiple vendors.

- PCB Design and Layout Assistance: Professional engineers help optimize your design for manufacturing efficiency

- Component Sourcing and Procurement: Access to over 200 global suppliers ensures parts availability and competitive pricing

- PCB Fabrication: Manufacturing of bare circuit boards from 1 to 64 layers using various materials

- Surface Mount and Through-Hole Assembly: Precise placement of components using advanced SMT and DIP technologies

- Quality Testing and Inspection: Multiple testing stages including ICT, FCT, AOI, and X-ray inspection

- Final Assembly and Packaging: Complete product fulfillment including enclosure assembly when needed

- Shipping and Logistics: Direct delivery to your specified location with tracking and documentation

“Turnkey PCB assembly providers handle everything from sourcing the smallest resistor to delivering the final tested product. This comprehensive service approach has revolutionized how electronics companies bring products to market.” – Electronics Tutorials

Options for Prototype and High-Volume PCB Assembly

Whether you’re launching a new gadget or scaling up production, flexible assembly options are essential for bringing your project to life. Professional PCB assembly providers offer a range of tailored solutions to match your workflow, from initial prototypes to mass production.

-

Quick-Turn Prototyping: Get your prototypes assembled rapidly, often within days, allowing for fast design iterations and early testing. This option is ideal for refining your circuit before scaling up.

-

High-Volume Production: Support for large-scale runs ensures your assemblies are manufactured consistently and efficiently, leveraging automated SMT lines and stringent quality controls for repeatability.

-

Box Build and Final Assembly: Beyond populating PCBs, comprehensive services can include integrating boards into enclosures, wiring, labeling, and preparing the finished product for end-users.

-

Inventory and Logistics Management: Advanced providers can store components, manage procurement, and handle shipping directly to your customers or distribution centers—removing the logistical headaches from your plate.

-

Flexible Assembly Types: Choose from full turnkey (provider sources all parts), partial turnkey (mix of supplied and sourced components), or consignment (you supply all parts). This flexibility lets you decide how much control you retain over the supply chain.

-

Specialized Finishes and Testing: Services often extend to RoHS and non-RoHS assembly, lead-free processes, conformal coating for environmental protection, and rigorous functional and in-circuit testing to guarantee reliability.

By leveraging these assembly options, you can shorten development cycles, manage costs, and ensure consistent quality—regardless of your project’s scale or complexity.

Turnkey PCB Assembly vs Traditional PCB Assembly

Understanding the differences between turnkey PCB assembly and traditional methods helps you make better decisions. Furthermore, this comparison reveals why many companies are switching to turnkey solutions.

| Aspect | Turnkey PCB Assembly | Traditional PCB Assembly |

|---|---|---|

| Vendor Management | Single provider handles everything | Multiple vendors require coordination |

| Lead Time | 30-40% faster completion | Longer due to handoffs between vendors |

| Cost Structure | Economies of scale, lower admin costs | Higher overhead from multiple relationships |

| Quality Control | Integrated testing throughout process | Testing may occur at different stages |

| Communication | Single point of contact | Multiple communication channels needed |

The Complete Turnkey PCB Assembly Process

The turnkey PCB assembly process follows a systematic approach that ensures quality and efficiency. Additionally, each step builds upon the previous one to create a seamless workflow.

-

- Design Review and DFM Analysis: Engineers review your design files and provide feedback for manufacturing optimization

- Bill of Materials (BOM) Analysis: Component sourcing engineers analyze your BOM and suggest alternatives for cost savings or availability.

- BOM Quotation Requirements:

To receive an accurate BOM (Bill of Materials) quote, you’ll need to provide the following details:- Part quantities needed for your assembly

- Reference designators that indicate component placement on your PCB

- Manufacturer names and full part numbers for each item

Providing this information ensures procurement specialists can match your exact requirements, secure compatible alternatives if necessary, and deliver precise cost estimates within a short turnaround.

- Component Procurement: Professional purchasing agents source all components from verified suppliers with quality certifications

- PCB Fabrication: Bare circuit boards are manufactured according to your specifications using advanced technologies

- Surface Mount Technology (SMT) Assembly: Automated placement of surface mount components with precision placement machines

- Through-Hole Assembly: Manual or automated insertion of through-hole components as needed

- Soldering and Reflow: Professional soldering processes ensure reliable electrical connections

- In-Circuit Testing (ICT): Automated testing verifies electrical connectivity and component functionality

- Functional Testing (FCT): Complete system testing ensures the PCB operates according to specifications

- Final Inspection and Packaging: Visual inspection, packaging, and preparation for shipment

According to Circuit Insight, this integrated approach reduces potential quality issues by eliminating handoff errors between different vendors.

How to Get a Quote for Turnkey PCB Assembly

Securing an accurate quote for turnkey PCB assembly is straightforward when you know what to expect. Here’s a step-by-step overview to help you get started:

-

Assembly Cost Estimation: Next, use the provider’s assembly quote tool to determine labor and assembly costs. This often requires uploading your PCB design files (Gerbers and Centroid data) and detailing assembly requirements such as component types, quantities, and placement preferences.

-

Bill of Materials (BOM) Submission: For precise parts sourcing and pricing, submit a complete Bill of Materials. Be sure to include quantities, reference designators, manufacturer names, and part numbers. The provider’s procurement team will analyze the BOM and respond—typically within a business day—with component availability, lead times, and detailed parts pricing.

-

Review and Place Your Order: Once you’ve reviewed all quote details—covering fabrication, assembly, and component sourcing—you’re ready to move forward at your convenience. Most companies make the order process simple and secure via their online platform.

This streamlined quoting process ensures you have a clear understanding of costs and timelines before production begins.

Key Benefits of Turnkey PCB Assembly

The advantages of turnkey PCB assembly extend far beyond simple convenience. In fact, these benefits can significantly impact your business’s bottom line and competitiveness.

Reduced Lead Times

Streamlined workflows eliminate delays between different manufacturing stages. Consequently, projects complete 30-40% faster than traditional methods. This acceleration happens because there are no waiting periods for vendor handoffs or communication delays.

Significant Cost Savings

Companies typically save 10-20% on total project costs through several mechanisms:

- Economies of scale in component purchasing

- Reduced administrative overhead

- Lower logistics and shipping costs

- Elimination of markup from multiple vendors

Enhanced Quality Control

Integrated quality systems ensure consistent standards throughout the process. Moreover, advanced testing equipment like 3D X-ray and automated optical inspection catches defects early.

Simplified Project Management

A single point of contact eliminates coordination headaches. Furthermore, you receive unified reporting and status updates throughout the project lifecycle.

Professional PCB design and layout services ensure optimal performance

Advanced SMT assembly lines handle components as small as 01005

Comprehensive testing ensures every PCB meets quality standards

How Turnkey PCB Assembly Reduces Costs and Lead Times?

The cost and time benefits of turnkey PCB assembly come from several specific mechanisms. Understanding these factors helps explain why this approach delivers such significant advantages.

Streamlined Supply Chain Management

Turnkey providers maintain relationships with over 200 global suppliers. As a result, they can secure better pricing through volume purchasing and access alternative sources when components become scarce. This supplier network also eliminates the time you would spend sourcing components individually.

Parallel Processing Capabilities

While your PCBs are being fabricated, components are simultaneously being sourced and prepared. Therefore, assembly can begin immediately after PCB fabrication completes. This parallel approach contrasts with traditional methods where each step waits for the previous one to finish.

Reduced Administrative Overhead

Managing multiple vendors requires significant administrative resources. However, turnkey assembly eliminates purchase orders, quality agreements, and communication with multiple suppliers. Studies from SMTA (Surface Mount Technology Association) show this can reduce project management time by up to 60%.

Optimized Logistics

Components ship directly to the assembly facility instead of to your location first. Consequently, this eliminates double handling, reduces shipping costs, and prevents delays from component inspection at your facility.

Quality Control in Turnkey PCB Assembly

Quality control in turnkey PCB assembly involves multiple testing stages and advanced inspection equipment. Furthermore, this comprehensive approach ensures that defects are caught early in the process.

Advanced Testing Methods

- In-Circuit Testing (ICT): Automated bed-of-nails testing verifies component placement and electrical connectivity

- Functional Circuit Testing (FCT): Tests the PCB under actual operating conditions to ensure proper functionality

- 3D Solder Paste Inspection (SPI): Measures solder paste volume and placement before component assembly

- 3D X-Ray Inspection: Examines hidden solder joints, especially for BGA and QFN components

- Automated Optical Inspection (AOI): High-resolution cameras detect component placement and soldering defects

- First Article Inspection (FAI): Comprehensive validation of the first production unit

Quality Certifications and Standards

Professional turnkey providers maintain multiple quality certifications including:

- ISO 9001 for quality management systems

- ISO 13485 for medical device manufacturing

- IATF 16949 for automotive electronics

- IPC standards for electronics assembly

- RoHS compliance for environmental safety

“The integration of multiple testing methods in turnkey PCB assembly creates a robust quality system that significantly reduces field failures and warranty claims.” – IPC Association

Choosing the Right Turnkey PCB Assembly Partner

Selecting the best turnkey PCB assembly partner is crucial for project success. Moreover, the right partner can become a long-term strategic advantage for your business.

Essential Criteria to Evaluate

Manufacturing Capabilities

- Number of SMT and DIP production lines

- Component placement accuracy and capabilities (down to 01005 components)

- PCB layer count capabilities (up to 64 layers)

- Special material handling (Rogers, Teflon, Flexible-Rigid)

Quality Systems and Certifications

- Industry-specific certifications (automotive, medical, aerospace)

- Testing equipment capabilities and calibration procedures

- Quality metrics and defect rate reporting

- Traceability systems for components and processes

Supply Chain Strength

- Number of approved component suppliers (look for 200+ suppliers)

- Component obsolescence management programs

- Alternative sourcing capabilities

- Inventory management and just-in-time delivery

Red Flags to Avoid

- Limited supplier network: Fewer than 50 suppliers may indicate sourcing challenges

- No industry certifications: Lack of ISO or industry-specific certifications

- Unclear communication: Difficulty getting clear answers about capabilities or processes

- No testing capabilities: Limited or outdated testing equipment

- Unrealistic pricing: Quotes significantly below market rates often indicate hidden costs

Common Challenges and How to Avoid Them

While turnkey PCB assembly offers many advantages, certain challenges can arise. However, understanding these potential issues helps you avoid them proactively.

Challenge 1: Communication Gaps

Problem: Misunderstandings about specifications or requirements can lead to delays and quality issues.

Solution: Establish clear communication protocols and designate specific points of contact. Additionally, request regular progress updates and milestone reports.

Challenge 2: Component Substitutions

Problem: Suppliers may substitute components without proper approval, affecting performance.

Solution: Require written approval for any component changes and establish clear guidelines for acceptable alternatives. Furthermore, request detailed documentation for all substitutions.

Challenge 3: Quality Variations

Problem: Inconsistent quality between production batches can cause field failures.

Solution: Insist on comprehensive testing protocols and request quality reports for each batch. Moreover, establish clear quality metrics and acceptance criteria upfront.

Challenge 4: Intellectual Property Concerns

Problem: Sharing design files and specifications may raise IP protection concerns.

Solution: Execute comprehensive non-disclosure agreements and work with providers who have strong IP protection policies. Additionally, consider working with providers in regions with strong IP enforcement.

Frequently Asked Questions About Turnkey PCB Assembly

What is the main difference between turnkey PCB assembly and traditional PCB manufacturing?

Turnkey PCB assembly provides an end-to-end solution managed by a single provider, including design, sourcing, assembly, and testing. In contrast, traditional PCB manufacturing often involves multiple vendors, requiring you to coordinate each step independently. This difference results in significantly reduced lead times and simplified project management.

Is turnkey PCB assembly more expensive than other methods?

While upfront costs can appear higher, turnkey PCB assembly generally results in 10-20% lower total costs. These savings come from reduced project management overhead, fewer delays, and economies of scale in component purchasing. Additionally, the time savings often justify any initial cost premium.

How long does turnkey PCB assembly take?

Turnkey PCB assembly can reduce lead times by 30-40% compared to traditional methods. Typical timelines range from 2-4 weeks for standard projects, depending on complexity and component availability. Rush services can deliver prototypes in as little as 4-8 hours for PCB fabrication.

Can I provide my own components for turnkey PCB assembly?

Yes, many turnkey providers offer partial turnkey services where you can consign specific components. However, full turnkey PCB assembly typically includes the provider sourcing all components to ensure compatibility and warranty coverage. Consigning components may affect lead times and quality guarantees.

What testing methods are used in turnkey PCB assembly?

Professional turnkey PCB assembly includes multiple testing methods such as:

- In-circuit testing (ICT) for electrical connectivity

- Functional testing (FCT) for operational verification

- Automated optical inspection (AOI) for visual defects

- X-ray inspection for hidden solder joints

- 3D solder paste inspection (SPI) for process control

How do turnkey providers handle component obsolescence?

Experienced turnkey providers maintain component lifecycle databases and proactively identify obsolescence risks. They also maintain relationships with multiple suppliers to source alternatives and often suggest design modifications to use more readily available components. According to Semiconductor Digest, this proactive approach can prevent 90% of obsolescence-related delays.

What industries benefit most from turnkey PCB assembly?

Turnkey PCB assembly particularly benefits industries with stringent quality requirements such as:

- Automotive electronics (requiring IATF 16949 certification)

- Medical devices (requiring ISO 13485 compliance)

- Aerospace and defense (requiring AS9100 standards)

- Industrial automation and control systems

- Telecommunications and networking equipment

What are the minimum order quantities for PCB assembly services?

Most turnkey PCB assembly providers cater to a range of project sizes, with minimum order quantities (MOQs) typically starting as low as 1 to 5 assembled boards for prototypes or small batches. For example, well-known industry suppliers like MUstar both offer low-volume options—ideal if you’re launching a new design or need just a handful of units for testing. This flexibility allows startups, makers, and small businesses to access professional assembly services without committing to large production runs. For higher-volume needs, MOQs generally scale up, but the industry trend favors accommodating both small and medium volume orders to support everything from rapid prototyping to mid-sized production.

Conclusion: Transform Your Electronics Manufacturing with Turnkey PCB Assembly

Turnkey PCB assembly represents the future of electronics manufacturing, offering unprecedented efficiency, quality, and cost-effectiveness. By consolidating design, sourcing, fabrication, assembly, and testing under one roof, this approach can reduce your lead times by up to 40% while cutting total project costs by 10-20%.

The key benefits include streamlined project management, enhanced quality control, and access to global supplier networks that ensure component availability even during shortages. Moreover, working with a single provider eliminates the complexity of coordinating multiple vendors while providing better visibility into your project status.

When choosing a turnkey PCB assembly partner, focus on their manufacturing capabilities, quality certifications, and supplier network strength. Look for providers with over 200 global suppliers, industry-specific certifications, and advanced testing equipment to ensure your projects meet the highest standards.

Ready to Experience the Benefits of Professional Turnkey PCB Assembly?

At Mustar, we’ve been delivering high-precision turnkey PCB assembly solutions for over 25 years. With 20 SMT lines, access to 200+ global suppliers, and certifications for automotive, medical, and industrial applications, we’re ready to accelerate your next project.

- ✓ Get PCB samples in as fast as 4-8 hours

- ✓ Save 30-40% on lead times with our integrated process

- ✓ Access professional component sourcing and BOM optimization

- ✓ Benefit from comprehensive testing and quality assurance

Or call our expert team at +86-136 8883 2535

Mustar projects