Contents

- What is ATE Testing?

- Why is ATE Testing Essential in PCBA?

- Understanding the differences between ATE, ICT and FCT

- The Core Components for an ATE System

- Types of ATE tests

- Market Analysis for ATE Testing

- Mustar’s Advantage

- Real-world applications and case studies ATE testing is used widely across

- How to Implement ATE Testing into Your PCBA Workflow

- How ATE Testing Boosts the Product Value

- FAQs about ATE testing

- Conclusion

What is ATE Testing?

Automated test equipment (ATE) is computer-controlled testing equipment that tests the functionality of PCBAs (Printed Circuit Board Assembly). ATE automates the testing process by simulating and measuring real-world signals. This provides a reliable solution for verifying electronic performance prior to final product integration.

Why is ATE Testing Essential in PCBA?

ATE testing is essential in PCBA because it ensures that the PCBA will perform exactly as intended. Manual testing is becoming inefficient as circuits and components become more complex. ATE provides high-speed, precise, and consistent validation. This reduces defective product rates, while ensuring industry compliance.

Understanding the differences between ATE, ICT and FCT

| Test Type | Full Name | Purpose | Automation | Suitable Stage |

|---|---|---|---|---|

| ICT | In-Circuit Testing | Detects shorts, opens, component values | Semi-auto | Early in the production |

| FCT | Functional Circuit Test | Testing assembled PCB functionality | Manual | The final production stage |

| ATE | Automated Test Equipment | Functional system testing fully automated | Full-auto | High-volume production |

ATE is known for its high-throughput, reproducibility, and ability to handle complex PCBA scenarios.

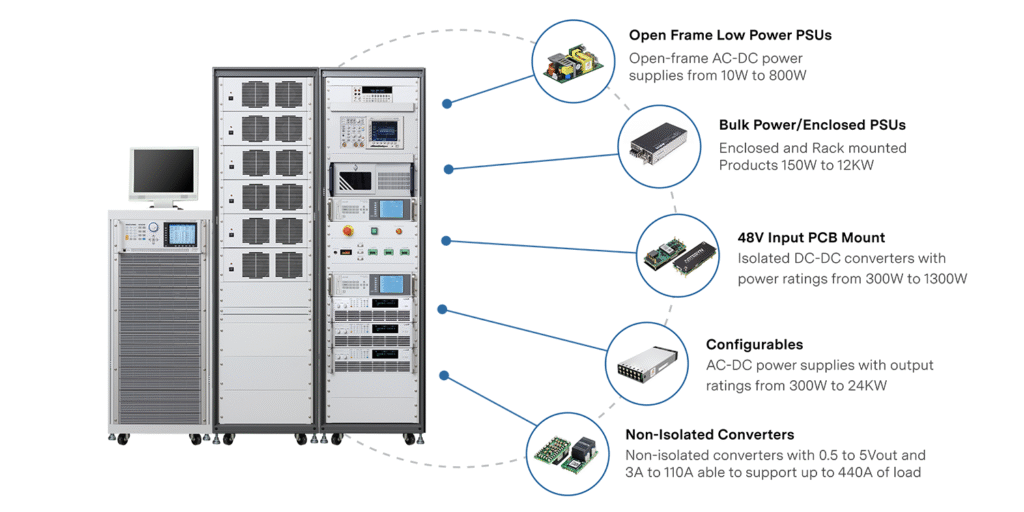

The Core Components for an ATE System

-

Test Control: A PC industrial or embedded system is usually used.

-

Handler/Prober: Positions unit to be tested.

-

Interface test adapter (ITA).: Connects PCBA and ATE.

-

Measurement instruments: power meters, waveform Generators, digital I/Os.

-

Control software: LabVIEW or ATLAS to program and execute test.

Types of ATE tests

-

Digital Signal Testing

-

High-Speed Interface Testing (USB, Ethernet, etc. )

-

Power Supply Verification

-

RF & Wireless Test

-

Functional Load Test

-

Simulation of Sensors and Actuators

Market Analysis for ATE Testing

| Metric | 2024 Value | Forecast (2030/2033) | CAGR (2025-30) |

| Global ATE Market | $7.75 Billion | $10.19 Billion (2030) | 4.8% |

| Market for PCB-specific ATE | $1.5-4.5 Billion | $2.8-7.8 Billion (2032/3) | 6.5% – 7.5% |

| Asia-Pacific Market Share | 50% global | The fastest growth by 2030 | Leading CAGR region |

Data sources: Grand View Research, Verified Market Reports ,LinkedIn Insights, Data Intelo

Mustar’s Advantage

Mustar(About Us) deploys high-precision ATE testing solutions tailored to the customer’s designs and applications. Our services include:

-

Custom fixture development

-

Test program design

-

Real-time data logging & reporting

-

Integration with SMT lines and post-assembly line

-

Traceability from end-to-end and quality assurance

Real-world applications and case studies ATE testing is used widely across

-

Automotive Electronics : Verifying the ECU, radar and infotainment board

-

Medical Devices : Ensure safe and stable operation for diagnostic PCBs

-

Consumer Electronics : mass testing of smart homes and wearable boards

Mustar’s automated ATE setup helped a medical device manufacturer reduce test time by 40% and increase pass rates by 15%.

How to Implement ATE Testing into Your PCBA Workflow

-

Test coverage requirements should be defined

-

Customize or develop the fixture

-

Create test scripts and logic

-

Integrate with the production environment

-

Validate pilot runs with calibration

-

Run full-volume tests with reporting

How ATE Testing Boosts the Product Value

-

Increases customer confidence and reliability

-

RMA rates are reduced

-

Ensures faster market entry via compliance with industry standards (ISO/IEC 17025)

-

Helps win contracts with strict quality requirements

FAQs

Q. What is the difference between ICT and ATE?

A: ICT focuses primarily on static checks such as shorts, opens, and resistance values. ATE, however, validates real-world functionality by using dynamic signals simulations and responses.

Q. Is ATE testing expensive?

A: While the upfront cost may be higher, ATE significantly reduces defects and improves production efficiency, leading to long-term savings.

Q. Which industries rely the most on ATE technology?

A: Due to their strict quality and reliability standards, the automotive, medical, telecommunications, and high-end consumer electronic industries are the most common users.

Q. How can I tell if my project requires ATE?

A: ATE testing should be performed if your PCBA contains complex signal processing, a high volume of components, or safety-critical features.

Conclusion

ATE testing plays a critical role in ensuring the functional integrity and reliability of PCBA in modern electronics. With growing product complexity and shrinking time-to-market windows, integrating automated testing is not just a quality measure—it’s a strategic necessity. At Mustar, we bring years of experience and technology to help our partners optimize every stage of their PCBA validation lifecycle.

Contact Mustar to learn how ATE testing can improve your PCBA performance.

Mustar projects:

[…] Functional testing (FCT) or ATE […]

[…] FR4 has become the mainstream PCB substrate material due to its comprehensive cost-performance ratio and performance, suitable for most general scenarios. In FR4 material applications, Mustar provides FR4 PCB Assembly solutions with strict IPC-A-610E quality standards and 100% functional testing. […]