Contents

Why are PCBA prototyping files so important?

The prototyping process validates if your PCB design works, if components are correctly matched, and if assembly is possible. Any missing or incorrect documentation during prototyping can lead to soldering failures, circuit faults, or mismatched electrical characteristics–wasting time, resources, and expensive components.

Three essential files for PCBA Prototyping

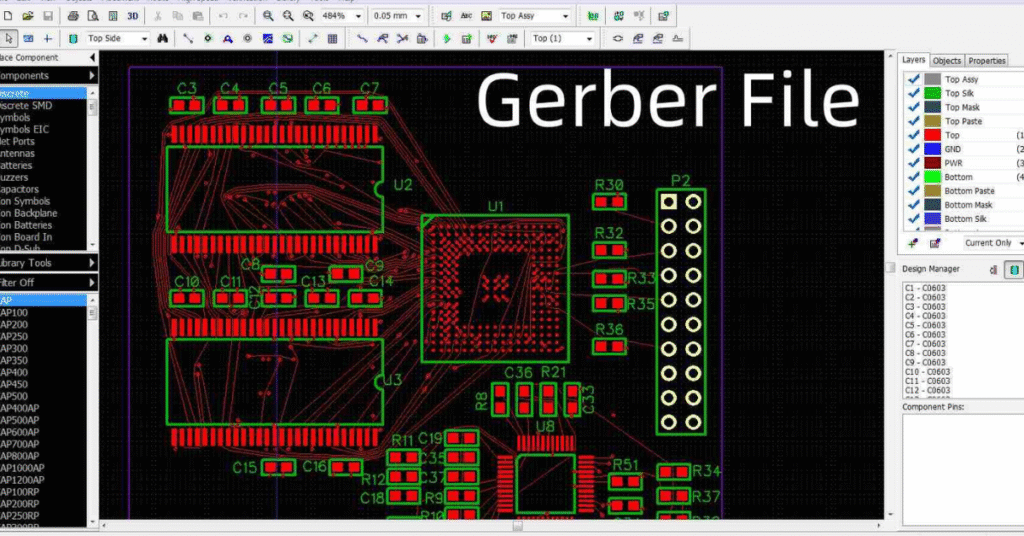

1. Gerber Files: The Blueprint for Your PCB

Gerber Files is the standard file format for PCB layers. It’s critical to manufacturing processes like routing, drilling and solder masking.

Common Gerber files include:

-

.gtl– Top copper layer -

.gbl– Bottom copper layer -

.gts/.gbs– Solder mask layers -

.gto/.gbo– Silkscreen layers -

Drill file

Tips:

-

Export in RS-274X Format

-

Define the board size, thickness and units (mm/mil)

-

Consistently name your files and include all layers

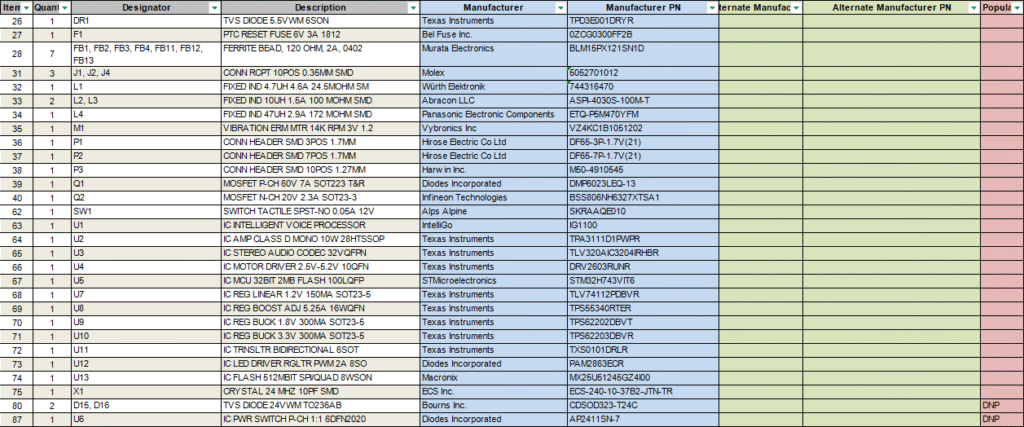

2. BOM File (Bill Of Materials) – Component list

The BOM file is an important document that informs the manufacturer of what components they should procure, where to place them and if any parts can be substituted.

The standard BOM should include the following:

| Ref Designator | Part Number | Package | Quantity | Brand | Substitutes are allowed | Notes |

|---|

Tips:

-

Include part numbers as well as preferred brands (e.g. Murata, TI or ST).

-

Specificate which parts cannot be replaced and are therefore critical.

-

Package names should match your PCB design

3. Placement Coordinates for SMT Placement Files

This document, also known as the PnP or placement file is used by SMT to accurately place components onto the PCB using X/Y coordinates.

Standard PnP Fields include:

-

Reference designator

-

Coordinates X and Y

-

Rotation (angle of rotation)

-

Package Type

Tips:

-

Use the same units of measurement (mm or mil).

-

Define the origin clearly

-

Save in CSV, TXT or Excel formats for compatibility

Optional but Recommended Files

| File | Purpose |

|---|---|

| Assembly Drawing | Reduces errors by displaying part orientation and location. |

| 3D File (STEP). | Validates mechanical compatibility with enclosure fit |

| Test Plan | Functional testing (FCT) or ATE |

| Process Instructions | For special requirements like BGA underfill, pin forming, etc. |

Mustar, Your PCBA Prototyping Expert Partner

Mustar is a leading one-stop PCBA manufacturing company based in Shenzhen, China. Mustar has over 25-years of experience as well as a global presence in 98 different countries . Mustar offers PCB manufacturing, electronic component sourcing and PCB assembly all under one roof.

Mustar’s Advantages

-

Fast Turnaround

-

8-hour quick-turn PCB fabrication

-

PCBA prototyping in 3-7 days

-

Two dedicated prototyping lines

-

-

Engineering Support

-

Gerber, BOM and PnP files can be reviewed for free

-

DFM to help prevent production issues

-

-

No MOQ

-

Minimum order quantity is not required

-

Ideal for design studios, startups and pilot runs

-

-

Advanced Manufacturing Facility

-

16 SMT lines and 32 AOI machines for 100% functional testing

-

Certification for automotive (IATF 16949) and medical (ISO 13485) production

-

-

Efficient Component Sourcing

-

Purchase agents with 50+ years of experience

-

500K+ IC part database

-

Original and authorized supply chains only

-

FAQs

❓1. What is PCBA prototyping and why is it important?

A: PCBA prototyping is the process of assembling a small batch of circuit boards to test a new design. It helps identify potential issues early and ensures the design is production-ready, saving time and costs before mass manufacturing.

❓2. What files are required for prototyping?

A: You’ll need three key files: Gerber files (for PCB layout), BOM (Bill of Materials), and Pick & Place files (for SMT machine coordinates). Providing accurate files is critical for successful PCBA prototyping.

❓3. What happens if my BOM is incomplete or has errors?

A: An incomplete BOM can delay your PCBA prototyping process. Missing part numbers, packages, or unclear substitutes can lead to sourcing issues or assembly mistakes. Mustar’s engineering team offers free BOM review to avoid such problems.

❓4. Can I request PCBA prototyping without minimum order quantity?

A: Yes! At Mustar, there is no MOQ. Whether you need one piece or a small batch, we support fast-turn PCBA prototyping with flexible volumes.

❓5. How long does PCB prototyping usually take?

A: With complete and correct files, PCB prototyping at Mustar typically takes 3–7 working days. PCB fabrication can be completed in as fast as 8 hours.

❓6. Do you help check my prototyping files before production?

A: Absolutely. Mustar offers free DFM file checking and technical support to ensure your Gerber, BOM, and Pick & Place files are error-free before production starts.

❓7. Can you source components for my PCBA prototype?

A: Yes. Mustar has a team of 50+ sourcing professionals and access to over 500,000 ICs. We provide fast and reliable electronic component sourcing for your PCBA prototyping needs.

❓8. What industries do you support for PCBA prototyping?

A: Mustar supports PCBA prototyping for medical devices, automotive, industrial control, new energy, and consumer electronics, with certifications like ISO 13485 and IATF 16949.

Conclusion: Let Mustar Simplify Your PCBA Prototyping Process

The first step towards successful mass production is prototyping. Mustar offers PCBA prototyping tailored to your specific needs, whether you are developing medical devices or industrial controls.

Are you ready to prototype your design?

Send us your Gerber, BOM and Pick & Place Files today. Mustar will review your files for free, and provide you with a quote in 24 hours.

Mustar projects: