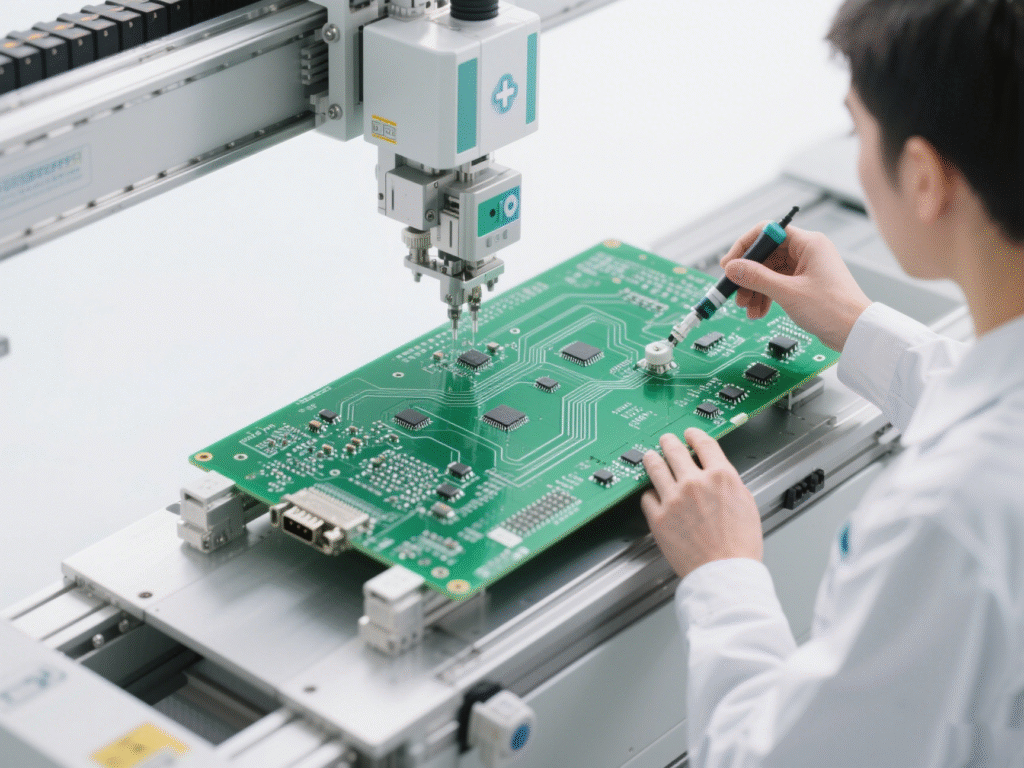

High-Reliability Medical PCBA Solutions

We specialize in delivering precision-engineered PCBAs for critical medical applications, ensuring strict compliance and superior performance.

WHY CHOOSE US

Our Medical PCBA Capabilities

Our Medical PCBA Capabilities ensure precision, reliability, and full compliance with international medical standards to support advanced healthcare technologies.

ISO 13485 certified production

ISO 13485 certified production ensures our PCBA manufacturing meets the stringent quality and regulatory requirements of the medical device industry.

SMT, THT, mixed-technology capabilities

We offer SMT, THT, and mixed-technology assembly capabilities to meet diverse design requirements and ensure optimal performance for complex medical PCBA applications.

Class 10K cleanroom assembly available

Class 10K cleanroom assembly ensures a controlled, low-particulate environment for producing high-reliability medical PCBA with superior cleanliness and safety.

Traceable components sourcing

Traceable components sourcing guarantees full transparency and accountability throughout the supply chain, ensuring quality and compliance for every medical PCBA we build.

Why Choose Us

Choose Us for Your Medical PCBA Needs

With over 15 years of experience in PCBA manufacturing, we specialize in delivering high-reliability solutions for the medical industry. Our strict control over materials and processes ensures consistent quality and compliance with regulatory standards. We offer fast prototyping, on-time delivery, and flexible support for both low-volume and high-mix orders. Backed by a professional engineering team and a dedicated medical project group, we provide expert technical guidance and personalized service from development to production.

What we offer

Optimization Solutions Provided For Free

We offer comprehensive optimization solutions at no additional cost, helping you refine your PCBA design for better functionality, reliability, and manufacturability. Our experienced engineering team conducts in-depth reviews to identify potential improvements in layout, component selection, thermal management, signal integrity, and production efficiency—ultimately reducing time-to-market and total project costs while ensuring compliance with medical industry standards.

Sign NDA

High standard confidentiality measures, signed confidentiality agreement, to ensure that 100% of the documents are not leaked.

Expert Sourcing Engineers Cut Costs, Ensure Quality

More than 50 electronic component sourcing engineers with over 8 years experience, help you to optimize project cost basic on ensuring quality.

100+ Expert Sales for Your Turnkey PCBA Solutions

More than 100 rich experience sales serve you on professional Turnkey PCBA.

Certifications & Compliance

ISO 13485: Medical devices QMS ISO 9001: Quality Management RoHS / REACH compliance IPC-A-610 Class II & III workmanship Full documentation support for audits

We provide PCBA services for a wide range of medical devices

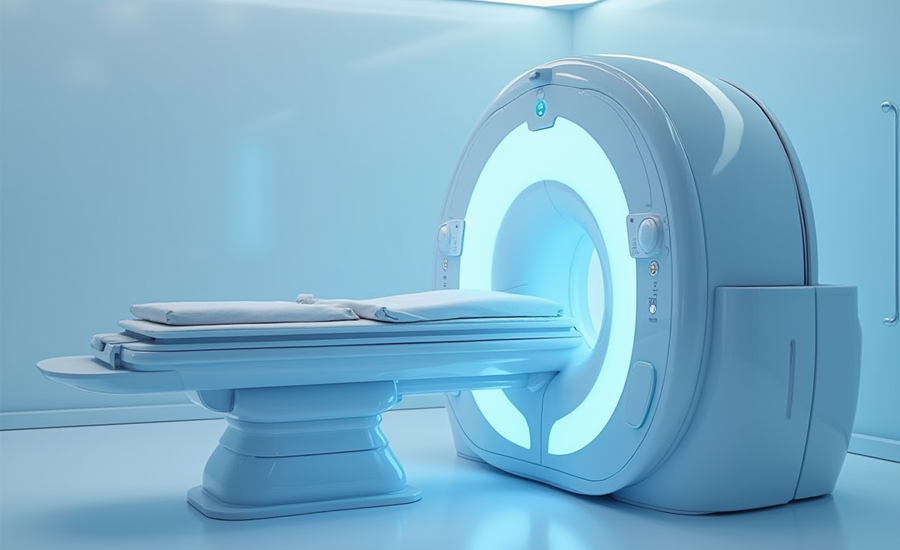

PCBA Solutions for Medical Imaging Equipment

PCBA Solutions for Medical Devices

PCBA Solutions for Ventilators

PCBA Solutions for Infusion pumps

PCBA Solutions for Wearable Health Devices

PCBA Solutions for

Portable Medical Devices

Our Customers

Established Clients

Walmart

Partnered in OEM consumer electronics PCBA production with rapid lead times and cost-effective solutions.

Danfoss

Provided high-reliability PCBA for industrial control and HVAC systems, meeting strict European quality standards.

3B medical

Supplied precision PCBA for respiratory and sleep therapy devices, ensuring ISO 13485 medical compliance.

Q-loud

Delivered customized IoT control boards with secure communication protocols, supporting their smart home initiatives.

Factory Overview

At present, our factory is 12,000 square meters with more than 600 employees (Including more than 100 professional International sales, more than 50 Components sourcing engineers with over 8 years’ experience, more than 50 Quality control personnel).

There are 20 SMT lines (6 SMT lines are specially used for the production of Medical and Automotive products), 2 Fast sample preparation lines, 5 DIP lines, 3 Post welding lines, 3 Assembly lines and 3 Test lines).

MU STAR

PCBA SOLUTION

At MU STAR, we deliver end-to-end PCBA solutions covering PCB fabrication, component sourcing, SMT/DIP assembly, testing, and final integration. With over 25 years of experience and state-of-the-art facilities, we serve diverse industries including medical, automotive, new energy, and industrial automation. Whether you need rapid prototyping or large-scale production, our solutions ensure high reliability, customization flexibility, and strict quality control at every stage.

PCBA Solutions IN Reliability Medical

Precision-engineered PCBA solutions for critical medical devices, ensuring reliability, compliance, and patient safety.

PCBA Solutions IN New Energy Field

High-efficiency PCBA solutions for solar energy, EV systems, and smart power storage, driving sustainable innovation.

PCBA Solutions IN Industrial Control

Reliable and precise PCBA solutions for automation systems, PLCs, motor drives, and intelligent control units in industrial environments.

PCBA Solutions In Security Field

Secure and stable PCBA solutions for surveillance, access control, alarm systems, and smart security devices.

PCBA Solutions In Automotive Field

Advanced PCBA solutions for EVs, ECU systems, ADAS, and automotive electronics, ensuring safety, performance, and compliance.

HOW to order?

Get a customized quote at no cost—talk to our team today!

Submit Your Requirements

Upload your Gerber files, BOM list, assembly drawings, and any special process instructions.

Project Evaluation & Quotation

Our engineering team will review your files and provide a detailed quotation with lead time.

Order Confirmation & Payment

Confirm the quotation and production details, sign the order, and complete the payment.

Production & Delivery

We proceed with PCB manufacturing, component sourcing, and assembly, followed by quality testing and on-time shipment.

What People Think About Us

We are proud to earn the trust of our clients worldwide. Their feedback drives us to continuously deliver high-quality PCBA solutions, fast turnaround, and exceptional service for every project.

Mustar has been an outstanding partner for our PCBA needs. Their fast prototyping and consistent quality helped us speed up our product launches without any compromise on reliability.

We appreciate Mustar's flexibility and technical expertise. From small batches to large production runs, they always deliver high-quality PCBA assemblies on time and within budget.

Thanks to Mustar’s professional team and strict quality control, our medical devices have met international certification standards effortlessly. Highly recommended for any precision PCBA projects.

Frequently Asked Questions

Yes,we support 3-7 days fast proofing.

Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process. All documents from customers are never shared with any third parties. NDA can be signed.

There is no MOQ. We are able to handle small as well as large volume production with flexibility. We have two fast proofing production lines.

We can offer OEM service including PCBA making, PCB assembly, components sourcing. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

ln order to guarantee PCB product quality,usually tested by flying probe; electrical fixture; automated optical inspection (AOI); X-ray inspection for BGA parts; first article inspection (FAl), and so on.

Gerber or Eagle, BOM listing, PNP and Components Position.

Get In Touch

Contact Us

sales@mustarpcba.com

Tel

+86 136 8883 2535

+ 1 (347) 718 9175

Address

#602 ~ 603, Building C, Qianwan Key & Core Technology Industrial Park, Bao'an District, Shenzhen China