Contents

- Identifying the Heat Sources on Your PCBA

- PCB Layout Optimization for Thermal Balance

- Thermal Simulation & Validation: CFD Tools Matter

- Establishing a Robust Thermal Path

- Choosing the Right Thermal Interface Materials (TIM)

- Heatsinks, Shielding, and Structural Cooling

- Testing and Thermal Validation

- Intelligent Thermal Management Systems

- Material Choices & High-Tg Substrates

- Summary Table: Key Metrics for PCBA Thermal Optimization

- People Also Ask (With Expert Answers)

- Conclusion

🔍 1. Identifying the Heat Sources on Your PCBA

The first step to optimizing thermal performance is identifying heat-generating components. These usually include:

-

Power ICs and voltage regulators

-

High-frequency processors and FPGAs

-

RF modules and power amplifiers

-

LED drivers and MOSFETs

Use power consumption data and thermal resistance specifications (R<sub>θJA</sub>) to quantify heat load. Proper estimation enables more accurate thermal simulation and heat path planning.

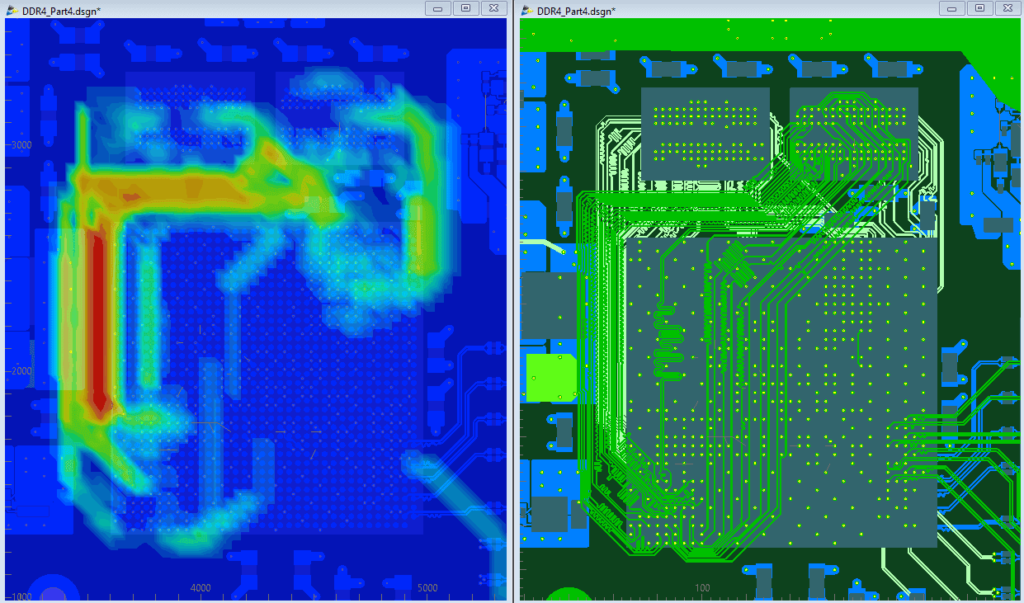

🧭 2. PCB Layout Optimization for Thermal Balance

Component placement plays a huge role in heat dissipation:

-

Distribute heat-generating components evenly to avoid hotspots.

-

Use large copper pours and thermal vias to expand the heat dissipation area.

-

Place high-power parts near edges or near board cutouts to facilitate airflow.

🧪 Data Insight: A recent case study shows that optimizing component layout reduced post-SMT solder defects from 5% to under 1%, largely due to improved thermal equilibrium during reflow soldering.

— Source: JC-PCBA.com

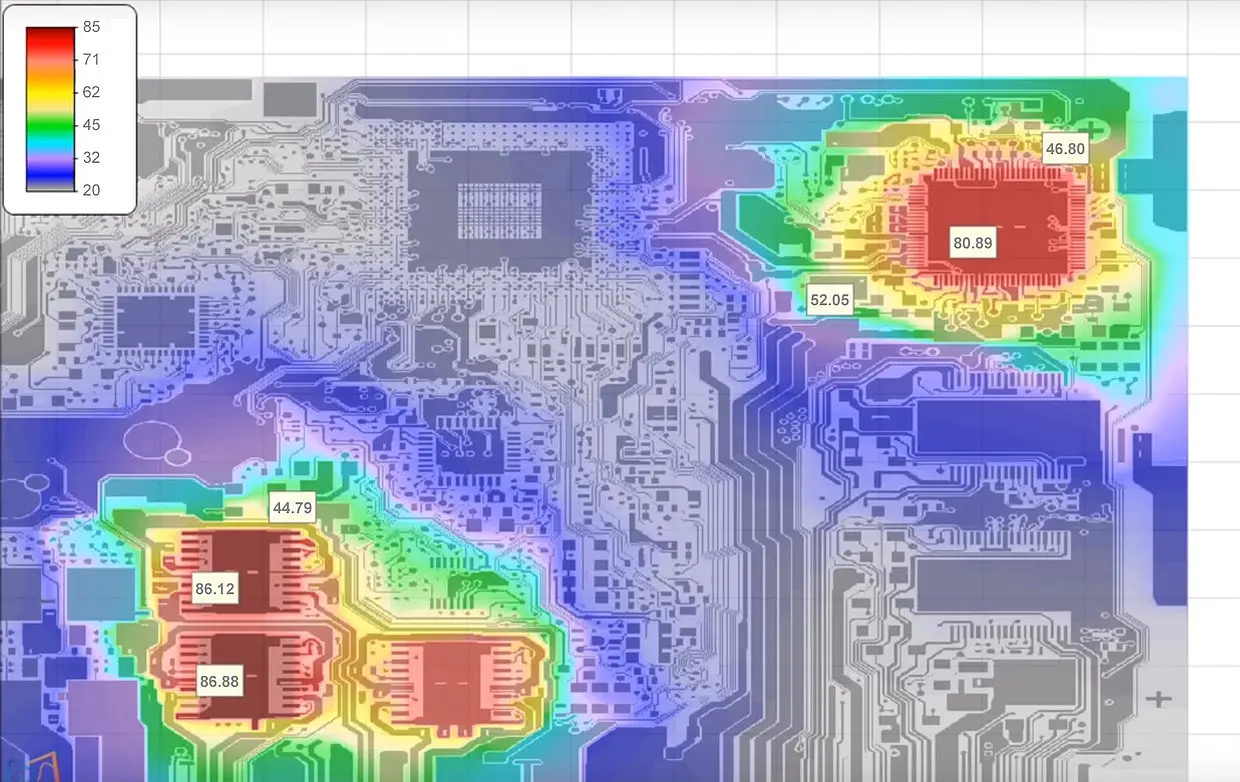

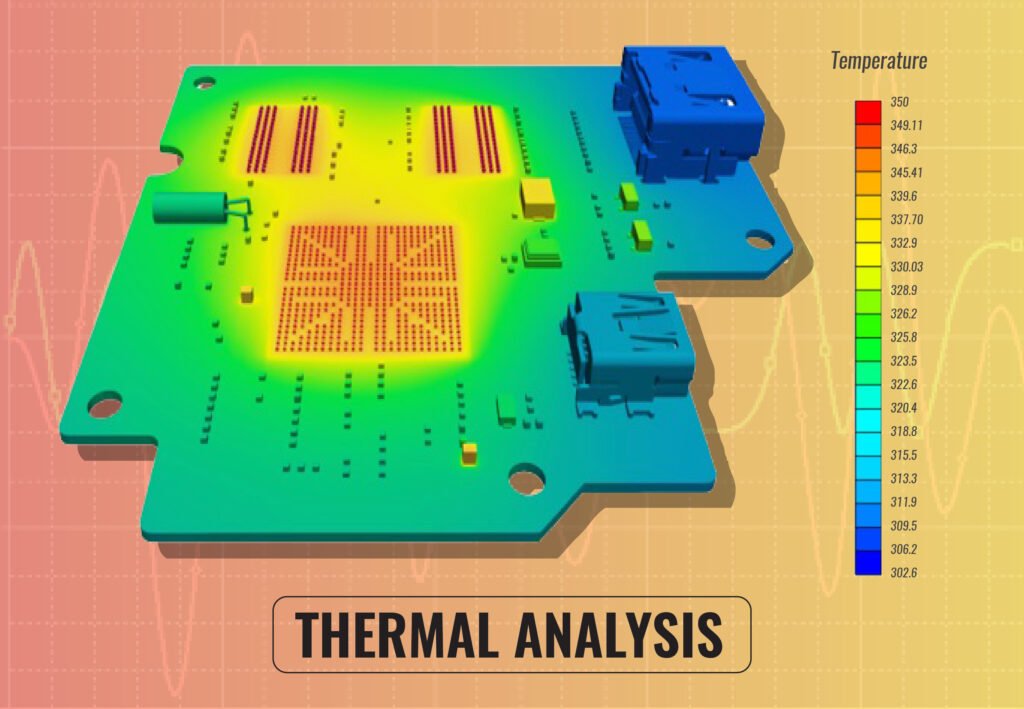

🧪 3. Thermal Simulation & Validation: CFD Tools Matter

Thermal simulation is critical for high-reliability applications (Why thermal simulation matters – Cadence Blog). Use tools like:

-

ANSYS Icepak

-

Mentor Graphics FloTHERM

-

SolidWorks Thermal Analysis

-

COMSOL Multiphysics

These platforms simulate airflow, temperature gradients, and identify heat concentration zones, allowing for design corrections early in the development cycle.

🔧 Statistic: More than 50% of electronics failures are due to thermal stress, especially in tightly packed assemblies.

— Source: Cadence PCB Design Blog, 2024

🔄 4. Establishing a Robust Thermal Path

A well-designed thermal path helps heat flow from components to the ambient environment. This includes:

-

Thermal vias under components

-

Direct heat spreading planes using copper pours

-

High-conductivity substrates, such as aluminum or metal-core PCBs (MCPCBs)

Multi-layer PCBs with internal copper planes can significantly reduce thermal resistance, especially when used with high-Tg materials.

🧱 5. Choosing the Right Thermal Interface Materials (TIM)

The choice of TIM can affect overall thermal resistance. Let’s compare common types:

| TIM Type | Typical Thermal Conductivity (W/m·K) | Notes |

|---|---|---|

| Thermal Grease | 3–5 | Excellent fill, requires reapplication |

| Thermal Pads | 1.5–4 | Easy to use, decent performance |

| Thermal Adhesives | 0.8–3 | Permanent bond, moderate performance |

| Phase-Change Materials | 1–5 | Activates with heat, great for long-term use |

📚 Reference: Wikipedia & Electronic Cooling Journal

🧊 6. Heatsinks, Shielding, and Structural Cooling

Depending on the power density, heatsinks or heat spreaders may be necessary:

-

Aluminum heatsinks offer 166–229 W/(m·K) conductivity

-

Copper heatsinks provide ~400 W/(m·K) but are heavier and costlier

-

Embedded heat pipes can transfer heat to remote cooling zones in complex enclosures

Combine structural design with airflow simulations to maximize efficiency.

🧪 7. Testing and Thermal Validation

Don’t skip this step. Use:

-

IR thermal cameras for hotspot mapping

-

Thermal couples to verify component temperatures

-

Accelerated aging tests to evaluate long-term thermal performance under real-world loads

🧠 8. Intelligent Thermal Management Systems

In complex applications, consider smart control systems:

-

Temperature sensors to trigger fan activation

-

PWM-controlled blowers for active cooling

-

Air duct design that channels cool air over the right areas

⚙ 9. Material Choices & High-Tg Substrates

Your substrate matters. Regular FR-4 has a Tg of ~130°C, which may not suffice. Instead, consider:

| Material | Tg Rating (°C) | Application |

|---|---|---|

| FR-4 | 130 | Low to medium-power circuits |

| High-Tg FR-4 | 170–180 | Industrial & automotive use |

| Ceramic | > 200 | Military, medical, high-frequency |

| MCPCB | 150–200 | LEDs, power converters |

🧾 10. Summary Table: Key Metrics for PCBA Thermal Optimization

| Design Element | Optimization Strategy | Key Benefit |

|---|---|---|

| Layout | Spread heat sources, thermal vias | Reduced hotspot formation |

| Simulation | CFD-based modeling | Early validation, fewer failures |

| TIMs | High conductivity pads/grease | Lower junction temperatures |

| Substrate | High-Tg FR-4 or MCPCB | Improved heat resistance |

| Testing | IR camera, thermocouples, aging tests | Proven performance under load |

❓ People Also Ask (With Expert Answers)

Q1: Why does a PCBA overheat?

Overheating is typically caused by poor layout, dense component placement, insufficient copper for heat conduction, or use of low thermal conductivity materials.

Q2: What are the best TIM materials for PCBA?

Silicone-based thermal grease and high-quality thermal pads are the most commonly used due to their balance of cost and performance.

Q3: What simulation software is best for thermal analysis?

ANSYS Icepak and FloTHERM are industry standards. SolidWorks Simulation and COMSOL are also great for integrated workflows.

Q4: Which PCB materials have better thermal performance?

High-Tg FR-4, aluminum-core MCPCBs, and ceramic substrates provide excellent thermal conductivity for demanding applications.

✅ Conclusion

Thermal design is no longer optional—it’s a competitive advantage. At Mustar, we don’t just manufacture PCBs. We engineer thermally reliable PCBA solutions that perform in the most demanding environments. Whether you’re working with high-power LEDs or mission-critical medical devices, our engineering team can help you optimize thermal pathways and improve product lifespan.

👉 Explore our PCBA capabilities at pcbamustar.com

Mustar projects: