Contents

What is PCB Box Build Assembly?

Box build assembly (also known as System Integration or Final Product Assembly) goes beyond PCBA and includes:

-

Mechanical enclosure assembly in plastic/metal

-

Integration of connectors, wiring, and cabling

-

Installation of display, sensor and antenna

-

Functional Testing & Firmware Programming

-

Product labeling & final packaging

Our turnkey service helps our clients reduce the complexity of their supply chains, minimize costs and get products to market quicker.

Why Choose Mustar For Box Build Services?

Mustar has over 25 year’s experience. We are more than a manufacturer, we are a partner who offers complete manufacturing solutions.

Unique advantages at a glance:

-

12,000m2 facility with 600+ highly skilled employees

-

20 SMT Lines including six dedicated to Automotive & Medical

-

Advanced features: 1-64-layer PCBs; 01005 components; HDI, BGA etc.

-

Global Supply Network with more than 200 vetted vendors

-

PCB samples within 4-8 hours

Our factory is able to support low-volume prototyping as well as mass production. This ensures flexibility and consistency at all stages of the product development.

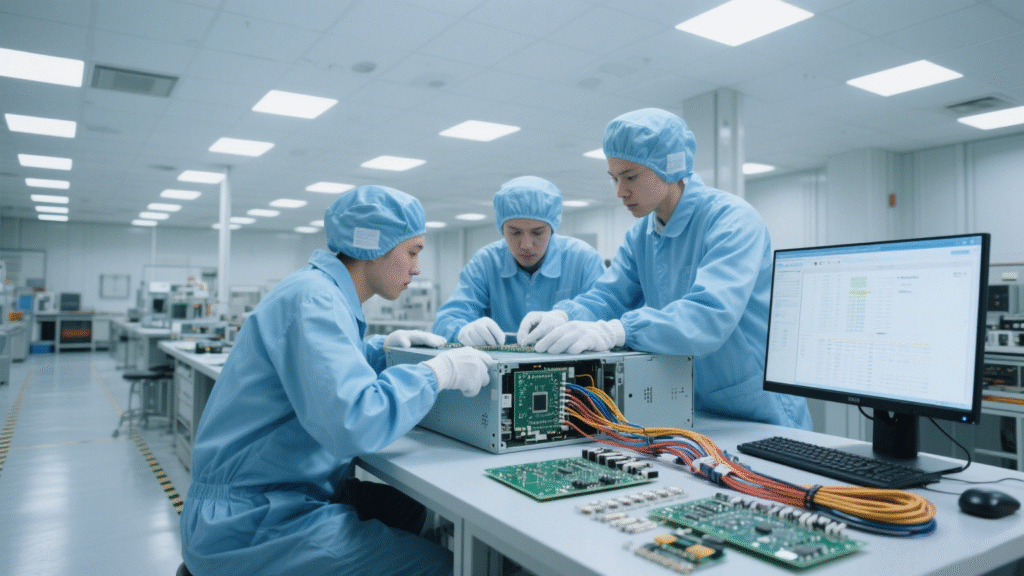

Comprehensive Box Build Capabilities

We can handle the entire box assembly process, including:

-

Assembly of PCBA in custom metal or plastic enclosures

-

Integrating connectors and switches, LCD displays, antennas

-

Connecting cables and power supplies

-

Final functional and burn-in testing

-

Barcodes, labels and documentation

-

Customized packaging & logistics support

We offer a solution that is scalable and tailored to meet your specific needs, whether you are manufacturing a Medical Monitoring Device or EV Charging Controller.

Industries We Serve

-

Automotive Electronics: ECU modules, ADAS systems

-

Medical Devices : wearable diagnostics and infusion pumps

-

New Energy: Power control boards, inverters

-

Industrial Control : smart meters, PLCs and embedded systems

FAQs (Frequently Asked Questions)

1. What services are included in the box build assembly service?

Our box-build service includes PCB assembly and enclosure integration. It also covers wiring, testing, packaging, and labeling. Turnkey solutions help reduce vendor coordination, allowing customers to launch quicker.

2. Do you supply enclosures, or will I have to provide them?

We can do both. We can either source your enclosure or you can provide us with one.

3. What qualifications do you have?

Mustar has been certified by ISO13485 for medical devices, ISO9001 for quality management and IATF16949 for automotive. Our production processes are certified to international standards.

4. Can you handle both low-volume prototypes and mass production?

Yes. Yes.

5. How long does it typically take to build PCBAs and boxes?

-

PCB prototyping: 4-6 hours

-

Standard PCBA: 3-7 days

-

Full box build: 7-15 day depending on complexity of materials.

Conclusion

Mustar goes beyond PCB assembly with complete box-build solutions to streamline your production and accelerate time-to market. We are the ideal partner for high precision PCBAs and enclosure integration. With our 25 years of expertise, advanced SMT line, and industry leading certifications, you can rely on us. Our team can support you at every stage, from prototyping through final assembly and delivery, whether you are developing medical devices, automotive electronic systems, or industrial control system.

🚀READY TO START?

Mustar is your PCBA and box build assembly partner. Our team of experts is ready to help you with your project by providing technical insight, rapid prototypes, and quality manufacturing.

Contact Mustar today and discover how our PCBA expertise can accelerate your project from concept to market success!

Mustar projects: