| Manufacturer | Experience | Key Certifications | Specialties | Sample Turnaround |

|---|---|---|---|---|

| Mustar | 25+ Years | ISO9001, IATF16949, ISO13485, RoHS | Automotive, Medical, New Energy | 4-8 Hours |

| Advanced Circuits | 30+ Years | ISO9001, AS9100, IPC | Aerospace, Defense | 24 Hours |

| TTM Technologies | 50+ Years | ISO9001, AS9100, ITAR | Military, Aerospace | 5-7 Days |

| Sanmina | 40+ Years | ISO9001, ISO14001 | Industrial, Telecom | 3-5 Days |

| NCAB Group | 35+ Years | ISO9001, UL, IPC | Consumer Electronics | 2-3 Days |

Quick comparison of top PCB assembly manufacturers in the USA, highlighting key differentiators and capabilities.

Contents

- What is PCB Assembly? Complete Process Explained

- Top 10 PCB Assembly Manufacturers in USA (2025)

- 5 Key Benefits of Choosing USA PCB Assembly Manufacturers

- PCB Assembly Market Size & Growth Statistics

- How to Choose the Right PCB Assembly Partner: 8-Point Checklist

- Common PCB Assembly Challenges & Solutions

- Why Choose Mustar for Your PCB Assembly Needs

- Frequently Asked Questions

- Conclusion

What is PCB Assembly? Complete Process Explained

PCB assembly is the process of soldering electronic components onto a printed circuit board (PCB) to create a functional electronic device. Moreover, this critical manufacturing step transforms a bare PCB into a working electronic product that powers everything from smartphones to medical devices.

The PCB Assembly Process Breakdown

The PCB assembly process typically involves several key stages. First, manufacturers prepare the bare PCB through drilling, plating, and applying solder mask. Next, they apply solder paste using stencils to create precise patterns.

Following this preparation, the assembly process begins with component placement. Surface Mount Technology (SMT) allows manufacturers to place tiny components like resistors, capacitors, and integrated circuits with incredible precision. Additionally, Through-Hole Technology (THT) handles larger components that require stronger mechanical connections.

After component placement, the boards undergo reflow soldering in specialized ovens. Subsequently, quality control teams perform multiple inspection stages including Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Circuit Testing (FCT).

“Modern PCB assembly can handle components as small as 01005 (0.4mm x 0.2mm), requiring precision equipment and experienced technicians to achieve consistent results.”

Top 10 PCB Assembly Manufacturers in USA (2025)

Choosing the right PCB assembly manufacturer in USA requires understanding each company’s unique strengths and capabilities. Furthermore, the following manufacturers represent the industry’s leading providers of high-quality PCB assembly services.

1. Mustar – Leading Turnkey PCB Assembly Solutions

Mustar stands out as a comprehensive PCB assembly manufacturer with over 25 years of experience. Notably, their 12,000 square meter facility houses 20 SMT lines and employs more than 600 skilled professionals. Additionally, Mustar specializes in automotive, medical, and new energy applications with relevant industry certifications.

2. Advanced Circuits – Aerospace & Defense Specialist

With over 30 years of experience, Advanced Circuits focuses on high-reliability applications. Moreover, their AS9100 and ITAR certifications make them ideal for aerospace and defense projects requiring strict quality standards.

3. TTM Technologies – Military & Aerospace Leader

TTM Technologies brings 50+ years of expertise to military and aerospace PCB assembly. Consequently, their ITAR registration and security clearances enable them to handle sensitive government contracts effectively.

4. Sanmina – Industrial Electronics Expert

Sanmina excels in industrial and telecommunications PCB assembly with 40+ years of experience. Furthermore, their global manufacturing network ensures consistent quality and supply chain reliability.

5. NCAB Group – Consumer Electronics Focus

NCAB Group specializes in consumer electronics PCB assembly with 35+ years of market presence. Additionally, their strong supplier relationships help manage component sourcing challenges effectively.

Additional Notable Manufacturers

- Sierra Circuits – Known for quick-turn prototypes and RF/microwave applications

- Tempo Automation – Specializes in fast prototyping with digital manufacturing

- Screaming Circuits – Focuses on quick-turn assembly services

- MacroFab – Offers cloud-based manufacturing platform

- Cosmic Circuits – Provides comprehensive turnkey solutions

5 Key Benefits of Choosing USA PCB Assembly Manufacturers

Selecting a PCB assembly manufacturer in USA offers numerous advantages over offshore alternatives. Moreover, these benefits often justify the investment for companies prioritizing quality and reliability.

1. Superior Quality & Certifications

USA manufacturers maintain strict adherence to international quality standards. For instance, companies like Mustar hold ISO9001, IATF16949 (automotive), and ISO13485 (medical) certifications. Additionally, these certifications ensure consistent quality and regulatory compliance across all production runs.

2. Enhanced IP Protection & Security

Intellectual property protection remains significantly stronger in the USA compared to many offshore locations. Furthermore, established legal frameworks and enforcement mechanisms protect your designs and proprietary technologies effectively.

3. Faster Turnaround Times

Domestic PCB assembly manufacturers offer impressive turnaround times for both prototypes and production runs. Notably, Mustar provides PCB samples in just 4-8 hours, while most USA manufacturers deliver prototype assemblies within 24-48 hours.

Turnaround Time Comparison:

- Prototypes: 4-48 hours (USA) vs 5-10 days (Offshore)

- Small batches: 3-7 days (USA) vs 2-4 weeks (Offshore)

- Production runs: 1-3 weeks (USA) vs 4-8 weeks (Offshore)

4. Supply Chain Reliability

USA-based manufacturers maintain robust supply chains with multiple domestic and international suppliers. Consequently, this diversification reduces risks associated with component shortages and shipping delays. Additionally, companies like Mustar work with over 200 global suppliers to ensure component availability.

5. Advanced Technology Capabilities

Leading USA manufacturers invest heavily in cutting-edge equipment and technologies. For example, Mustar’s facilities can produce PCBs up to 64 layers using advanced materials like Rogers, Teflon, and high-frequency substrates. Moreover, their capabilities include buried vias, blind vias, and embedded components.

PCB Assembly Market Size & Growth Statistics (2025)

The PCB assembly market continues experiencing robust growth driven by increasing demand across multiple industries. Furthermore, recent market analysis reveals compelling trends that highlight the industry’s expansion potential.

Current Market Valuation

According to Verified Market Reports, the global PCB assembly market reached $36.3 billion in 2024. Moreover, projections indicate the market will grow to $54.8 billion by 2033, representing a compound annual growth rate (CAGR) of 5.9%.

Key Market Statistics (2024-2025):

- Market Size: $36.3 billion (2024) → $54.8 billion (2033)

- Growth Rate: 5.9% CAGR

- Booking Growth: 59.6% year-over-year increase

- US Economic Impact: $1.2 trillion electronics manufacturing sector

Industry Growth Drivers

Several key factors drive the PCB assembly market expansion. First, automotive electronics demand continues surging due to electric vehicle adoption and advanced driver assistance systems. Additionally, medical device innovation requires increasingly sophisticated PCB assemblies for diagnostic and treatment equipment.

Furthermore, the new energy sector drives significant demand for PCB assemblies in solar inverters, battery management systems, and charging infrastructure. IPC (Association Connecting Electronics Industries) reports that renewable energy applications represent one of the fastest-growing PCB assembly segments.

Regional Market Trends

The USA maintains a strong position in high-value PCB assembly segments. Notably, American manufacturers excel in aerospace, defense, medical, and automotive applications where quality and reliability are paramount. Moreover, the recent emphasis on supply chain resilience has increased demand for domestic PCB assembly services.

How to Choose the Right PCB Assembly Partner: 8-Point Checklist

Selecting the ideal PCB assembly manufacturer in USA requires careful evaluation of multiple factors. Furthermore, this comprehensive checklist helps ensure you choose a partner capable of meeting your specific requirements.

1. Experience & Track Record

Look for manufacturers with extensive experience in your industry. For instance, Mustar’s 25+ years of experience includes over 500 types of automotive PCBAs and specialized medical device assemblies. Additionally, request case studies and customer references to verify their capabilities.

2. Industry Certifications

Verify that potential partners hold relevant industry certifications. Essential certifications include:

- ISO9001: Quality management systems

- IATF16949: Automotive quality standards

- ISO13485: Medical device quality management

- AS9100: Aerospace quality requirements

- IPC Standards: Electronic assembly standards

3. Technology Capabilities

Assess the manufacturer’s technical capabilities against your requirements. Advanced capabilities to consider include:

- Multi-layer PCB production (up to 64 layers)

- Advanced materials handling (Rogers, Teflon, flexible-rigid)

- Fine-pitch component assembly (01005, BGA, QFN)

- Embedded component technologies

- High-frequency and RF applications

4. Quality Control Processes

Evaluate the manufacturer’s quality control procedures thoroughly. Look for comprehensive testing capabilities including:

- In-Circuit Testing (ICT) for electrical verification

- Functional Circuit Testing (FCT) for operational validation

- 3D X-Ray inspection for hidden joint quality

- Automated Optical Inspection (AOI) for visual defects

- First Article Inspection (FAI) for process validation

5. Component Sourcing Network

A strong component sourcing network ensures project success and cost optimization. For example, Mustar maintains relationships with over 200 global suppliers and employs 50+ experienced sourcing engineers. Moreover, they guarantee 100% BOM compliance or provide approved alternatives.

6. Testing Capabilities

Comprehensive testing capabilities are essential for ensuring product reliability. Additionally, manufacturers should offer both standard and custom testing solutions tailored to your specific applications and industry requirements.

7. Customer Support

Evaluate the manufacturer’s customer support capabilities, including:

- Design for Manufacturability (DFM) reviews

- Engineering support and consultation

- Project management and communication

- Technical documentation and reporting

- Post-delivery support and warranty

8. Pricing Transparency

Request detailed pricing breakdowns that include all costs. Furthermore, reputable manufacturers provide transparent pricing with no hidden fees and offer cost optimization suggestions during the design review process.

“The best PCB assembly partners don’t just manufacture your designs – they help optimize them for better performance, reliability, and cost-effectiveness.”

Common PCB Assembly Challenges & Solutions

Understanding common challenges in PCB assembly helps you make better decisions when selecting a manufacturing partner. Moreover, experienced manufacturers like those featured in our guide have developed effective solutions for these recurring issues.

Material Cost Fluctuations

Challenge: Raw material and component prices can vary significantly due to market conditions, tariffs, and supply chain disruptions. Additionally, these fluctuations can impact project budgets and timelines unexpectedly.

Solution: Leading PCB assembly manufacturers maintain strategic supplier relationships and offer price protection programs. For instance, Mustar’s extensive supplier network allows them to source components at competitive prices while maintaining quality standards. Furthermore, they provide cost optimization suggestions during the design review process.

Component Sourcing Issues

Challenge: Component shortages and obsolescence can delay production and increase costs. Moreover, counterfeit components pose significant risks to product reliability and safety.

Solution: Experienced manufacturers maintain comprehensive supplier qualification programs and authorized distributor networks. Additionally, they offer component sourcing services with verified authentic parts and suggest suitable alternatives when necessary. Electronics Sourcing provides valuable insights into component sourcing best practices.

Quality Control Challenges

Challenge: Ensuring consistent quality across different production runs while meeting tight tolerances and specifications requires sophisticated processes and equipment.

Solution: Advanced manufacturers invest in state-of-the-art testing equipment and implement comprehensive quality management systems. For example, Mustar employs 3D SPI, X-Ray inspection, and multiple testing stages to ensure product reliability.

Quality Control Best Practices:

- Implement multiple inspection stages throughout the assembly process

- Use statistical process control (SPC) for continuous improvement

- Maintain traceability records for all components and processes

- Regular equipment calibration and maintenance schedules

- Comprehensive staff training and certification programs

Turnaround Time Pressures

Challenge: Balancing speed with quality while meeting aggressive project timelines requires efficient processes and flexible capacity management.

Solution: Successful manufacturers optimize their workflows and maintain flexible production capacity. Moreover, they offer expedited services for urgent projects without compromising quality standards. Additionally, effective project management and communication help prevent delays.

Why Choose Mustar for Your PCB Assembly Needs

Among the many PCB assembly manufacturers in USA, Mustar distinguishes itself through comprehensive capabilities, proven experience, and unwavering commitment to quality. Furthermore, their unique combination of advanced technology and customer-focused service makes them an ideal partner for demanding applications.

25+ Years of Proven Experience

Since 1998, Mustar has continuously evolved to meet changing industry demands. Moreover, their extensive experience spans over 500 types of automotive PCBAs, numerous medical device assemblies, and cutting-edge new energy applications. Additionally, this deep experience translates into practical solutions for complex manufacturing challenges.

Comprehensive One-Stop Solution

Mustar provides complete turnkey PCB assembly services under one roof. From initial PCB fabrication through final product testing, their integrated approach ensures consistency and accountability. Furthermore, their services include:

- PCB Manufacturing: 1 to 64-layer capabilities with advanced materials

- Component Sourcing: 200+ global suppliers with 100% BOM compliance

- Assembly Services: 20 SMT lines plus DIP and mixed technology capabilities

- Quality Testing: Comprehensive inspection and functional testing

- Enclosure Assembly: Complete product fulfillment services

Advanced 64-Layer Capability

Mustar’s advanced PCB manufacturing capabilities support the most demanding applications. Their ability to produce up to 64-layer PCBs using materials like Rogers, Teflon, and high-frequency substrates enables complex designs for aerospace, automotive, and telecommunications applications.

Extensive Global Supplier Network

With over 200 verified global suppliers and 50+ experienced sourcing engineers, Mustar ensures component availability and competitive pricing. Moreover, their professional purchasing team has 10+ years of experience managing complex BOMs and finding cost-effective alternatives when needed.

Industry-Specific Expertise

Mustar specializes in three key industries where quality and reliability are paramount:

- Automotive: IATF16949 certified with dedicated production lines for automotive electronics

- Medical: ISO13485 certified for medical device manufacturing with specialized clean room capabilities

- New Energy: Expertise in solar inverters, battery management systems, and EV charging equipment

Ultra-Fast Prototyping

Mustar’s industry-leading 4-8 hour sample turnaround time accelerates product development cycles significantly. Additionally, this rapid prototyping capability allows for quick design iterations and faster time-to-market for new products.

Comprehensive Certifications

Mustar maintains multiple industry certifications ensuring compliance with international standards:

- ISO9001: Quality management systems

- ISO13485: Medical device quality management

- IATF16949: Automotive quality systems

- ISO14001: Environmental management

- CE, RoHS, UL: Product safety and environmental compliance

Customer Success Stories

Mustar has successfully supported over 100 automotive electronics enterprises in rapidly growing their market presence. Furthermore, clients consistently praise their professional engineering support, reliable delivery schedules, and exceptional technical expertise.

“Mustar’s combination of advanced technology, quality certifications, and customer-focused service makes them an outstanding choice for companies requiring high-precision PCB assembly solutions.”

Frequently Asked Questions

What is the minimum order quantity for PCB assembly?

Most reputable PCB assembly manufacturers in USA, including Mustar, do not impose minimum order quantities. This flexibility allows customers to order everything from single prototypes to large production runs without penalties.

How long does PCB assembly typically take?

Turnaround times vary by complexity and quantity. Prototype assemblies typically take 1-3 days, while production runs require 1-3 weeks. However, expedited services can deliver samples in as little as 4-8 hours for urgent projects.

What certifications should I look for in a PCB assembly manufacturer?

Essential certifications include ISO9001 for quality management, plus industry-specific certifications like IATF16949 (automotive), ISO13485 (medical), or AS9100 (aerospace) depending on your application requirements.

How do I ensure component authenticity and quality?

Choose manufacturers that work exclusively with authorized distributors and maintain comprehensive supplier qualification programs. Additionally, request certificates of authenticity and traceability documentation for critical components.

Can PCB assembly manufacturers help with design optimization?

Yes, experienced manufacturers offer Design for Manufacturability (DFM) reviews to optimize designs for better assembly, reliability, and cost-effectiveness. This service often identifies potential issues before production begins.

For additional information about PCB assembly best practices, visit IPC’s official website which provides comprehensive industry standards and guidelines.

Conclusion: Partner with the Right PCB Assembly Manufacturer

Selecting the right PCB assembly manufacturer in USA is a critical decision that impacts your product’s quality, time-to-market, and overall success. Moreover, the comprehensive analysis presented in this guide demonstrates that American manufacturers offer significant advantages in quality, reliability, and innovation.

The PCB assembly market’s impressive growth trajectory—from $36.3 billion in 2024 to a projected $54.8 billion by 2033—underscores the industry’s vital role in modern electronics. Furthermore, this growth creates opportunities for companies that partner with the right manufacturing providers.

Key Takeaways for Your Decision

When evaluating potential partners, remember these critical factors:

- Experience matters: Choose manufacturers with proven track records in your specific industry

- Certifications ensure quality: Verify relevant ISO, automotive, medical, or aerospace certifications

- Technology capabilities: Ensure your partner can handle current and future design requirements

- Supply chain strength: Look for manufacturers with diverse, reliable supplier networks

- Quality control: Comprehensive testing and inspection processes are non-negotiable

Among the manufacturers evaluated, Mustar stands out for its comprehensive capabilities, industry-leading turnaround times, and commitment to quality excellence. Additionally, their 25+ years of experience, advanced 64-layer PCB capabilities, and industry-specific certifications make them an ideal partner for demanding applications.

Ready to Get Started?

Don’t let PCB assembly challenges slow down your product development. Whether you need rapid prototyping, high-volume production, or specialized assembly services, choosing the right manufacturing partner is crucial for your success.

Take Action Today

Experience the Mustar difference with industry-leading quality, lightning-fast turnaround times, and comprehensive turnkey solutions.

Get Your Free Quote in 24 Hours

✓ No minimum order quantity

✓ Free DFM review included

✓ Sample delivery in 4-8 hours

✓ 25+ years of proven expertise

Contact Mustar Today:

🌐 Visit: Get Your Free Quick Turn Quote →

📧 Email: sales@pcbamustar.com

📞 Call: +86 136 8883 2535

The electronics industry waits for no one. Moreover, partnering with an experienced, certified, and technologically advanced PCB assembly manufacturer like Mustar ensures your products meet the highest standards while reaching market faster than ever before.

Start your project today and discover why leading companies trust Mustar for their most critical PCB assembly needs. Furthermore, with comprehensive certifications, advanced capabilities, and customer-focused service, Mustar is ready to become your trusted manufacturing partner.

For the latest industry insights and PCB assembly trends, bookmark this page and follow Circuits Assembly Magazine for ongoing updates and technical developments in the PCB assembly industry.

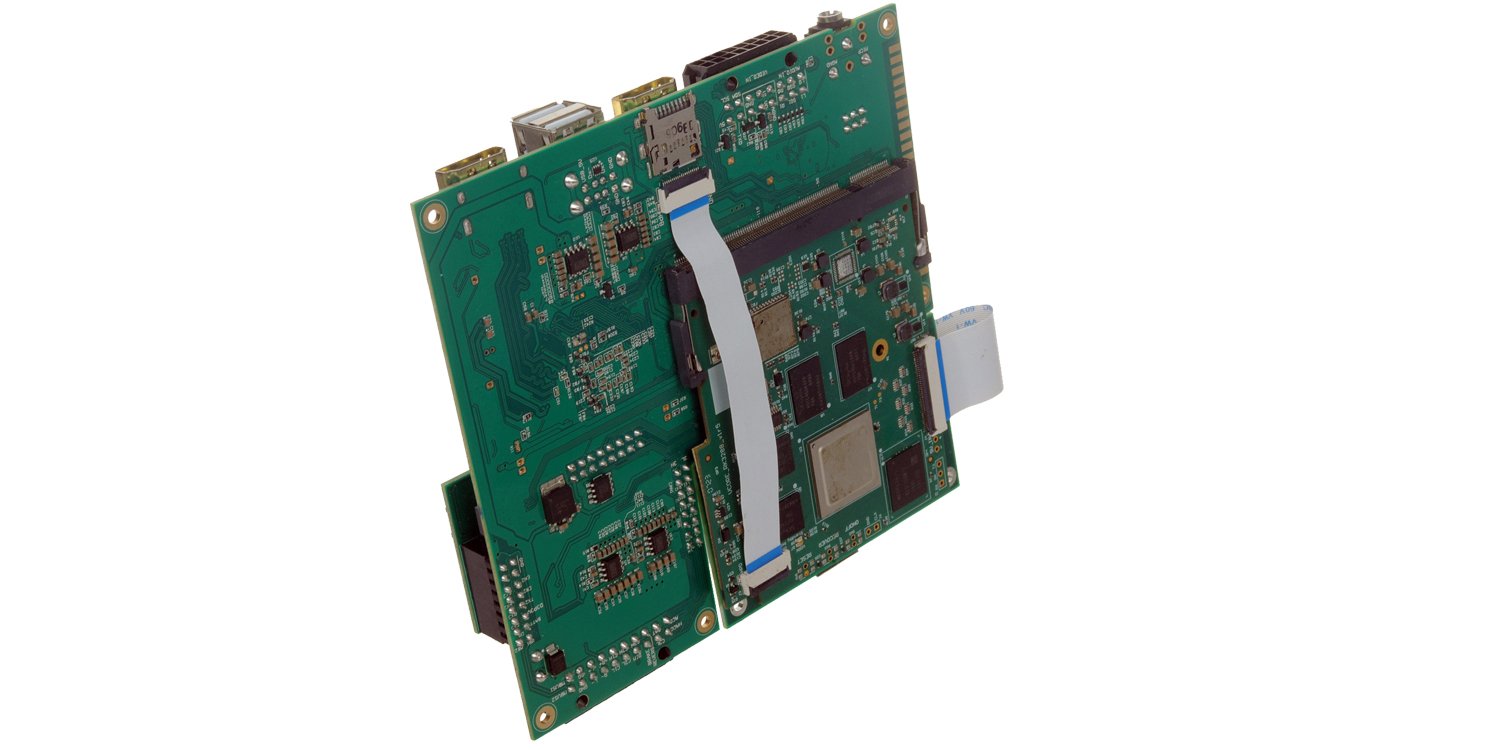

Mustar projects: