Contents

- Industry Background and Recycling Challenges – The Global Electronic Waste Surge & PCBA Complexity

- The Challenges of Recycling PCBA Waste

- Mustar Solutions and Practical Strategies

- Mustar’s technological innovations and customer-centric benefits

- Join Mustar Green PCBA Movement

- FAQs (Frequently Asked Questions)

- About Mustar

Industry Background and Recycling Challenges – The Global Electronic Waste Surge & PCBA Complexity

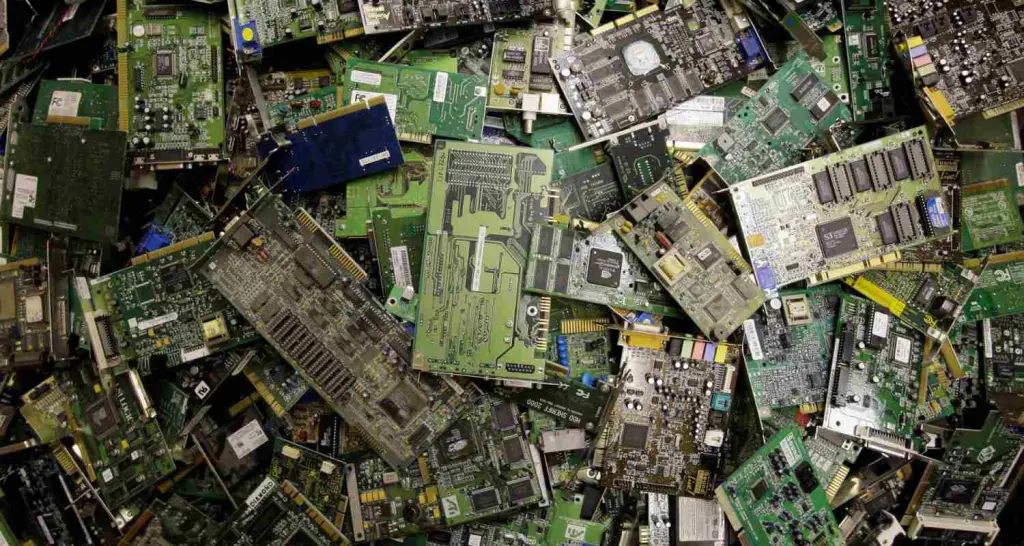

The global electronic waste (WEEE), which is estimated to reach 57,4 million metric tons in 2023 — a 3.1% rise from the year before — is growing rapidly. Only 20% of the waste generated is recycled properly, with the rest being disposed in landfills or by burning. This poses serious environmental risks.

PCBA waste is a subset of EWaste that includes complex multilayer boards, such as FR-4 or ceramic substrates. It also contains mixed solder alloys like lead and lead-free and dense populations of electronic parts such as BGAs andQFNs. The complexity of PCBA waste not only complicates the recycling process, but it also presents a risk for heavy metal and chemical contamination due to hazardous substances such as lead, palladium and gold. PCBA scrap is a valuable source of metals. Recycling it effectively is therefore both environmentally and economically imperative.

Many small and medium businesses lack access to recycling technologies and channels that are compliant. Mustar, a Shenzhen based PCBA turnkey manufacturing company with more than 25 years’ experience, is a champion of blending environmental stewardship with manufacturing efficiency, enabling its clients to achieve their growing ESG goals.

Mustar provides clients with early environmental compliance reports, enhancing brand reputations and supporting eco-conscious markets.

The Challenges of Recycling PCBA Waste

Complexity of Material Composition

-

Multilayer PCBs with 1 to 64 layers, using materials such as CIM-1 and CIM-3. Aluminum substrates are also available.

-

The recovery of mixed solder types containing toxic lead or alternatives that do not contain lead can be complicated.

-

Separation techniques are required for components with complex packaging and diverse component types.

Barriers to technical and process barriers

-

To maximize recovery, it is necessary to use precision chemical metallurgy when extracting precious metals like gold and palladium.

-

To minimize the release of toxic substances into the environment, it is important to use advanced methods of treatment such as thermal decomposition and chemical recycling.

Regulatory and Compliance Risks

| The Region of the South-East | Major Regulations and Standards | Compliance Focus |

|---|---|---|

| EU | RoHS Directive and WEEE Directive | Hazardous substance restrictions and mandatory take-back |

| China | Solid Waste Pollution Prevention Law | Mandates for strict pollution control and recycling |

| Global | ISO 14001 Environmental Management | Environmental management system compliance |

Mustar actively applies Design for Environment strategies to meet these requirements. These include limiting the use of mixed materials, and using modular designs that simplify recycling and reduce environmental footprint.

Mustar Solutions and Practical Strategies

Design-Level Prevention

-

The modular and easily disassembled PCBA structure allows for effective material separation.

-

Labeling recyclable materials clearly helps recyclers to reduce contamination and accelerate classification.

Case study: Mustar optimized the stacking of a PCBA for a medical device, reducing layers from eight to six. This simplification decreased material complexity by 25%, cut recycling processing time by 15%, and achieved a 12% cost saving in downstream waste management–showcasing measurable environmental and financial benefits.

Productivity and waste reduction

-

Lean manufacturing reduces the amount of raw PCB materials and solder scrap.

-

The use of tin-slag recycling techniques allows for the recovery of precious metals while reducing hazardous waste.

Closed-loop Systems and Recycling Partnerships

-

Mustar works with metal refineries, resin treatment facilities and other recycling companies to recycle PCBAs in an environmentally friendly manner.

-

The “PCBA Returned Discount Program” of the company encourages customers to return scrap board, lowering disposal costs and ensuring responsible handling.

Mustar’s technological innovations and customer-centric benefits

Advanced Materials and Processes

-

Mustar’s proprietary PCB materials are halogen free and deliver a 40% decrease in halogen emission during the manufacturing phase. This reduces toxic release risks by a significant amount.

-

The high-recycling solder pastes reduce environmental hazards as well as raw material costs by up to 20 percent.

-

Mustar has demonstrated its commitment to promoting sustainable production and restricting harmful chemicals by complying with ISO 14001 and RoHS directives.

Support for Customer Value and ESG

-

Mustar’s detailed environmental compliance documentation directly supports the ESG goals of customers, helping them to enhance their corporate responsibility and market position.

-

They offer a comprehensive range of services, including PCB design, component sourcing (over 500,000 ICs are available), assembly, fabrication (including automotive IATF 16949 and medical ISO 13485 certified lines), and quality testing according to IPC-A 610E and UL.

Future Vision

-

Mustar shares its commitment to sustainability in a transparent manner on the corporate platform. It invites industry collaboration for standard PCBA recycling initiatives and circular economy.

Conclusion: Join Mustar’s Green PCBA Movement

For clients: Mustar’s Green PCBA Program will help you reduce operational waste, while also leveraging the latest eco-friendly technologies and compliance expertise.

For Industry Partners Collaborate to promote standardized PCBA Recycling Processes in order to improve environmental impacts, reduce cost, and accelerate innovation for sustainable electronics manufacturing.

FAQs (Frequently Asked Questions)

Q1 – Why is PCBA waste recycling more difficult than other electronic wastes?

PCBA Waste is a complex waste consisting of multilayer substrates with mixed solder types and tightly integrated components. Its physical separation and chemical recovery are complicated.

Q2 – What are the main environmental regulations that govern PCB disposal?

Notable rules include the EU WEEE Directive, RoHS and China’s Solid Waste Pollution Prevention Law. These regulations mandate responsible recycling of hazardous materials and limit them.

Q3 – How can Mustar PCBAs be recycled from the beginning?

Applying Design for Environment (DFE), such as halogen free materials, modular designs and reduced layer count to allow for easier recycling and reduce environmental impact.

Q4 – Are precious metals recoverable from PCB?

It is possible, but requires sophisticated chemical recovery methods to efficiently recover gold, palladium and copper. This balances cost with environmental benefits.

Q5 – How can suppliers take part in Mustar’s recycling initiative?

Mustar offers a PCBA Return Discount program to clients who contact the company for scrap board returns. Clients will receive financial incentives as well as compliance assistance.

About Mustar

Mustar (Mu Star (Shenzhen) Industrial Co., Ltd.) is a PCBA turnkey solution provider based in Shenzhen. The company has more than 25 years of experience, and its clients span 98 different countries. The company is characterized by:

-

12,000 sqm factory, 600+ employees

-

16 SMT lines, including medical and automotive

-

Testing at the cutting edge: X-rays, AOIs, E-tests and functional testing

-

Certifications: ISO 9001, IATF 16949, ISO 13485, ISO 14001, RoHS

-

Expertise in medical, automotive, new energies, industrial control and consumer electronics

Mustar’s fast lead times, low minimum order quantities, affordable pricing and 24/7 engineering support make it the preferred partner for PCBA manufacturing in all parts of the world.

Mustar projects: