| Market Metric | Value / Forecast | Key Details |

|---|---|---|

| Global Medical PCB Market Size (2023) | USD 1.7 billion | Current market valuation |

| Projected Market Size (2032) | USD 3.2 billion | Nearly doubling in 9 years |

| Compound Annual Growth Rate (CAGR) | 7.2% | Steady, consistent growth |

| Key Growth Drivers | Rising chronic diseases, wearable devices, IoT integration | Technology and health trends |

| Leading Region | North America | Largest market share currently |

| Fastest Growing Region | Asia Pacific | Highest CAGR expected |

Contents

- What is Medical PCB Assembly?

- Applications of Medical PCB Assembly

- Unique Challenges in Medical PCB Assembly

- Key Requirements for Medical PCB Assembly

- Medical PCB Assembly Process

- How to Choose a Medical PCB Assembly Partner

- Future Trends in Medical PCB Assembly

- Frequently Asked Questions

- Conclusion

What is Medical PCB Assembly?

Medical PCB assembly is the specialized process of designing, manufacturing, and assembling printed circuit boards specifically for medical devices. Unlike standard electronics, medical PCBs must meet extremely strict safety and reliability standards because they directly impact patient health and safety.

The key difference between medical PCB assembly and regular electronics lies in the zero-tolerance approach. While a smartphone might occasionally freeze or restart, a medical device failure could be life-threatening. Therefore, medical PCB assembly requires rigorous quality control, specialized materials, and compliance with strict regulatory standards like ISO 13485 and FDA 21 CFR Part 820.

Applications of Medical PCB Assembly

Medical PCB assembly serves a wide range of healthcare applications. Each application has unique requirements, but all share the common need for exceptional reliability and safety.

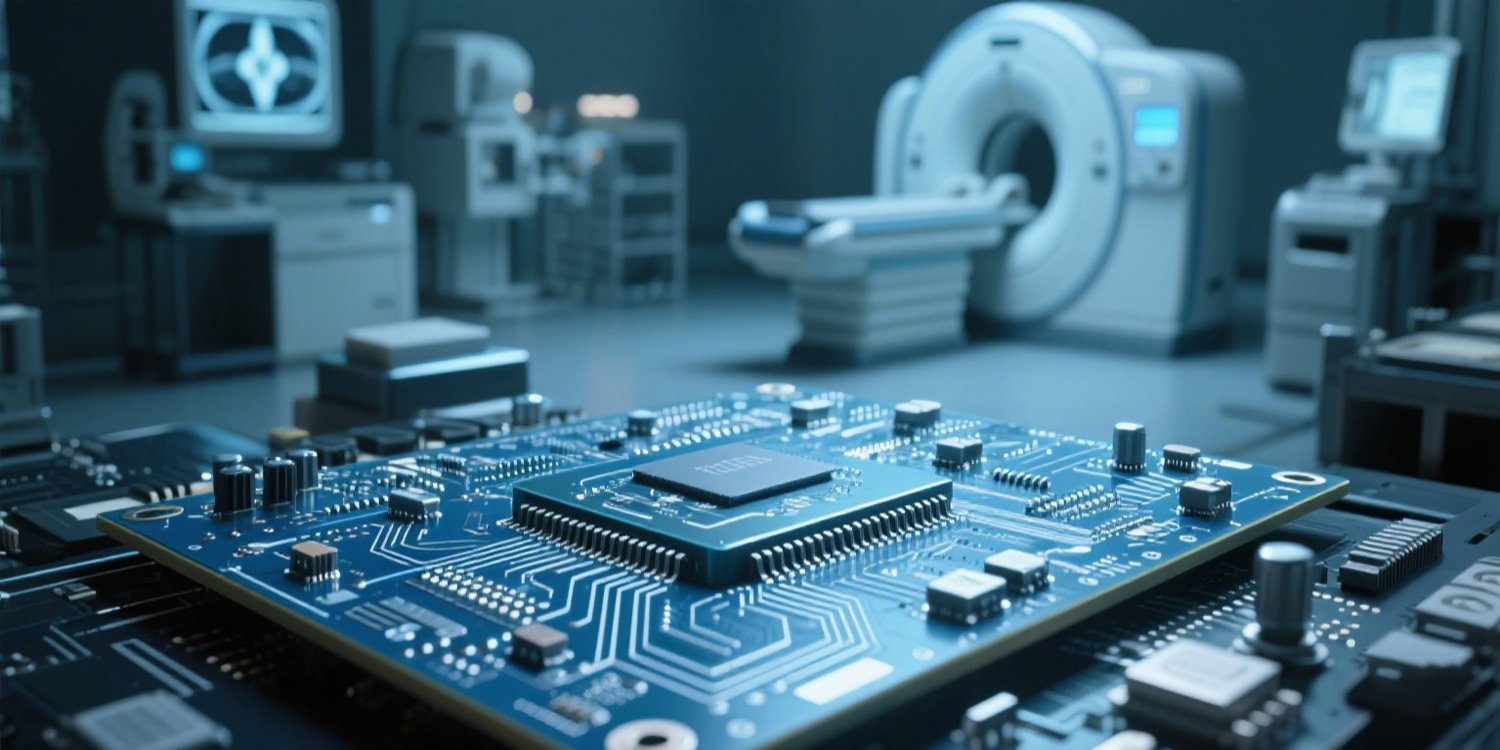

Diagnostic Equipment

Medical diagnostic equipment relies heavily on sophisticated PCB assemblies. MRI machines use complex multi-layer PCBs to process magnetic field data, while CT scanners require high-speed processing boards to reconstruct detailed images. Additionally, ultrasound machines depend on specialized PCBs for signal processing and image generation.

Monitoring Devices

Patient monitoring represents one of the largest segments in medical PCB assembly. Heart rate monitors use sensitive PCBs to detect cardiac rhythms, while glucose monitors require precise analog-to-digital conversion circuits. Furthermore, pulse oximeters and blood pressure monitors all depend on reliable PCB assemblies for accurate readings.

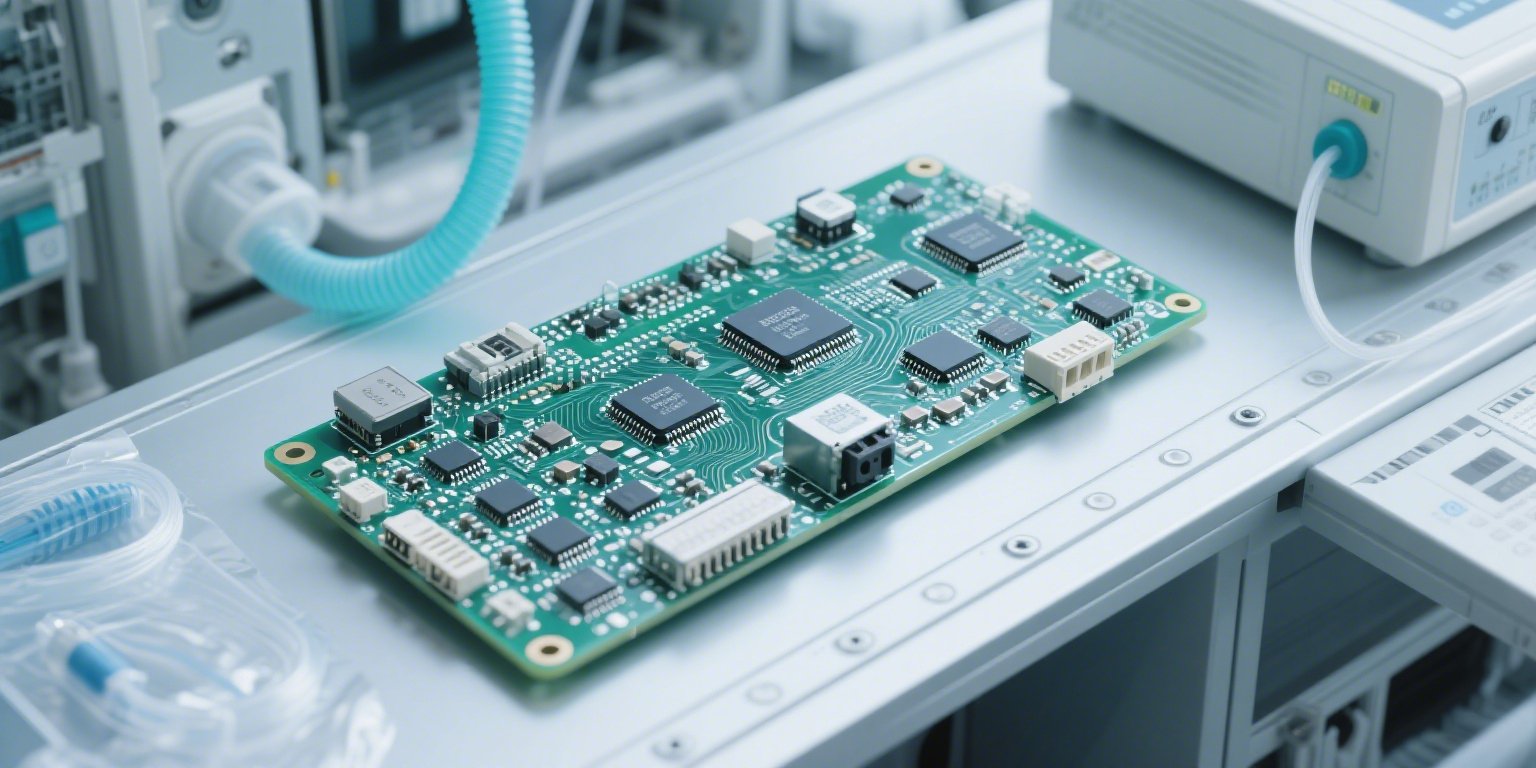

Therapeutic Devices

Life-sustaining therapeutic devices demand the highest quality medical PCB assembly. Pacemakers require ultra-miniaturized, biocompatible PCBs that can function flawlessly for years inside the human body. Similarly, infusion pumps and ventilators use sophisticated control PCBs to deliver precise medication doses and breathing support.

Medical Cosmetic Equipment

The growing field of medical aesthetics also relies on advanced PCB assembly. Laser skin treatment devices use high-power control PCBs to deliver precise energy levels. Moreover, radiofrequency and ultrasound cosmetic devices require specialized PCB assemblies for safe and effective treatments.

Unique Challenges in Medical PCB Assembly

Medical PCB assembly faces several unique challenges that set it apart from other electronics manufacturing. Understanding these challenges is crucial for successful medical device development.

Zero Tolerance for Failure

The most significant challenge in medical PCB assembly is the absolute requirement for reliability. Unlike consumer electronics, medical devices cannot afford to fail. Consequently, manufacturers must implement extensive testing, use high-grade components, and maintain strict quality control throughout the assembly process.

Regulatory Compliance Requirements

Medical PCB assembly must comply with numerous regulatory standards. The FDA requires adherence to 21 CFR Part 820, while international markets demand ISO 13485 certification. Additionally, manufacturers must maintain detailed documentation and traceability records for every component and process step.

Miniaturization Demands

Modern medical devices increasingly require smaller, more compact PCBs without sacrificing functionality. This miniaturization challenge forces engineers to use advanced techniques like HDI (High Density Interconnect) technology, embedded components, and multi-layer designs. Furthermore, thermal management becomes critical in smaller form factors.

Biocompatibility Needs

Medical PCBs, especially those in implantable devices, must use biocompatible materials. This requirement limits material choices and often increases costs. Moreover, manufacturers must ensure that all materials meet ISO 10993 biological evaluation standards for medical devices.

Key Requirements for Medical PCB Assembly

Successful medical PCB assembly requires adherence to specific requirements that ensure safety, reliability, and regulatory compliance. These requirements form the foundation of quality medical device manufacturing.

ISO 13485 and FDA Compliance

Medical PCB assembly facilities must maintain ISO 13485 certification, which demonstrates a comprehensive quality management system specifically designed for medical devices. Additionally, FDA compliance requires adherence to Good Manufacturing Practices (GMP) and detailed documentation of all processes.

Material Selection

Choosing the right materials is crucial for medical PCB assembly. FR-4 remains the most common substrate, but specialized applications may require polyimide for flexibility or ceramic substrates for high-frequency applications. Furthermore, all materials must meet flame retardancy requirements and biocompatibility standards when applicable.

Cleanroom Standards

Medical PCB assembly often requires cleanroom environments to prevent contamination. Class 10,000 or better cleanrooms are typically necessary, especially for implantable device PCBs. Moreover, personnel must follow strict protocols for gowning, equipment sterilization, and environmental monitoring.

Testing and Validation

Comprehensive testing is essential in medical PCB assembly. This includes In-Circuit Testing (ICT), Functional Circuit Testing (FCT), and environmental stress testing. Additionally, manufacturers must perform Design Verification and Validation (V&V) testing to ensure devices meet their intended specifications.

Medical PCB Assembly Process (Step-by-Step)

The medical PCB assembly process follows a structured approach that ensures quality and compliance at every stage. Understanding this process helps in planning and managing medical device projects effectively.

Design and Prototyping

The process begins with careful PCB design that considers medical-specific requirements. Engineers use Design for Manufacturability (DFM) principles to ensure the design can be reliably manufactured. Subsequently, prototypes are built and tested to validate the design before full production.

Component Sourcing

Medical PCB assembly requires high-reliability components from qualified suppliers. Component sourcing engineers verify that all parts meet medical-grade specifications and maintain proper certifications. Furthermore, traceability documentation must be maintained for every component used in the assembly.

SMT and Through-Hole Assembly Techniques

The assembly process typically combines Surface Mount Technology (SMT) and through-hole techniques. SMT assembly handles miniaturized components like 0201 resistors and fine-pitch BGAs. Meanwhile, through-hole assembly is used for larger components and connectors that require mechanical strength.

Inspection, Testing, and Quality Assurance

Multiple inspection and testing stages ensure assembly quality. Automated Optical Inspection (AOI) catches placement errors, while X-ray inspection reveals hidden solder joint defects. Additionally, electrical testing verifies functionality, and environmental testing ensures reliability under operating conditions.

Final Assembly, Packaging, and Certification

The final stage includes any additional assembly steps, such as enclosure installation or cable attachment. Products are then packaged in anti-static materials and properly labeled with traceability information. Finally, certification documents are prepared to accompany each shipment.

How to Choose a Medical PCB Assembly Partner

Selecting the right medical PCB assembly partner is crucial for successful medical device development. The chosen partner must demonstrate both technical capability and regulatory compliance.

Certifications to Look For

Your medical PCB assembly partner should hold essential certifications including ISO 13485 for medical device quality management, IPC-A-610 for electronic assembly standards, and relevant FDA registrations. Additionally, look for automotive certifications like IATF 16949, which often indicate advanced quality systems.

Experience and Expertise

Choose a partner with proven experience in medical PCB assembly. They should demonstrate successful projects in your specific medical device category and understand the unique challenges of medical electronics. Moreover, their engineering team should provide design support and DFM guidance.

Quality Management Systems

Evaluate the partner’s quality management system thoroughly. They should maintain comprehensive documentation, provide full traceability, and demonstrate continuous improvement processes. Furthermore, their quality system should include supplier qualification programs and change control procedures.

Future Trends in Medical PCB Assembly

The medical PCB assembly industry continues to evolve rapidly, driven by technological advances and changing healthcare needs. Understanding these trends helps in planning future medical device developments.

Wearable Devices

The growing popularity of wearable medical devices is driving demand for flexible and ultra-thin PCBs. These devices require specialized assembly techniques and materials that can withstand repeated flexing and body contact. Additionally, power management becomes critical in battery-powered wearable devices.

IoT Integration

Internet of Things (IoT) connectivity is becoming standard in medical devices. This trend requires PCB assemblies with integrated wireless modules, advanced security features, and cloud connectivity capabilities. Moreover, edge computing functionality is increasingly built into medical device PCBs.

Advanced Materials

New materials are enabling better performance in medical PCB assembly. High-frequency materials support 5G connectivity, while thermally conductive substrates improve heat dissipation. Furthermore, biodegradable materials are being developed for temporary implantable devices.

Frequently Asked Questions

Medical PCB assembly is the process of designing, manufacturing, and assembling printed circuit boards specifically for medical devices, ensuring high reliability, safety, and compliance with strict regulatory standards. These PCBs are critical components in devices such as pacemakers, diagnostic equipment, and monitoring systems, where failure is not an option due to patient safety concerns.

The main challenges include miniaturization and complexity of the PCBs, zero tolerance for failure, strict regulatory compliance (e.g., FDA, ISO 13485), and the need for biocompatible, durable materials. Ensuring traceability, rigorous testing, and cleanroom assembly are also critical to meet medical industry standards.

Medical PCB assembly must comply with regulations such as FDA 21 CFR Part 820 (Quality System Regulation), ISO 13485 (Quality Management System for medical devices), and IPC standards for electronics manufacturing. These ensure the safety, reliability, and traceability of medical PCBs throughout the production process.

Medical PCBs are used in a wide range of devices including implantable devices like pacemakers, diagnostic imaging equipment (MRI, CT scanners), patient monitoring systems, therapeutic devices (infusion pumps, ventilators), and cosmetic medical devices like laser treatment equipment.

Reliability is ensured through careful material selection (medical-grade substrates and components), design for manufacturability, cleanroom assembly, comprehensive testing (functional, environmental, X-ray inspection), and strict adherence to regulatory standards and quality management systems.

Medical PCB assembly requires higher reliability, stricter quality control, use of medical-grade materials, and compliance with more rigorous regulatory standards compared to other industries. The zero-failure tolerance and traceability requirements are significantly more demanding in medical applications.

Conclusion: Your Partner for Medical PCB Assembly Excellence

Medical PCB assembly represents one of the most demanding sectors in electronics manufacturing. The combination of strict regulatory requirements, zero-failure tolerance, and complex technical challenges requires specialized expertise and proven capabilities.

As the medical PCB market continues to grow at 7.2% CAGR, reaching $3.2 billion by 2032, choosing the right assembly partner becomes increasingly critical. Success in medical device development depends on partnering with a manufacturer that understands both the technical complexities and regulatory landscape of medical electronics.

Ready to Start Your Medical PCB Assembly Project?

Mustar brings over 25 years of experience in high-precision PCB assembly, with dedicated medical-grade production lines and ISO 13485 certification. Our team of 600+ professionals, including specialized sourcing engineers and quality experts, ensures your medical devices meet the highest standards of reliability and compliance.

From prototype to full production, we provide comprehensive turnkey solutions including PCB fabrication, component sourcing, assembly, testing, and enclosure assembly – all under one roof.

Get Your Medical PCB Quote TodayJoin over 100 medical device companies who trust Mustar for their critical PCB assembly needs. Contact our medical electronics specialists for a consultation on your next project.

Mustar projects: