Quick Reference: Top 8 Factors for Choosing a Reliable PCBA Manufacturer

| Factor | Why It Matters | What to Look For |

|---|---|---|

| Experience & Expertise | Reduces project risks | 25+ years, industry specialization |

| Certifications | Ensures quality standards | ISO 9001, IPC-A-610, industry-specific |

| Manufacturing Capabilities | Handles complex requirements | Advanced equipment, 64-layer PCBs |

| Quality Control | Prevents defects | Multiple testing stages, >95% FPY |

| Cost Transparency | Budget predictability | Detailed quotes, no hidden fees |

| Communication | Smooth project flow | Responsive support, English fluency |

| Location & Logistics | Delivery efficiency | Strategic location, reliable shipping |

| Value-Added Services | Complete solutions | Turnkey services, design support |

Key Industry Insight: The global PCB market is expected to reach $85.4 billion in 2025, growing at 5.5% annually. However, choosing the wrong PCBA manufacturer can cost you more than money—it can damage your product’s reputation and delay your time-to-market.

Contents

- What is PCBA Manufacturing and Why Does Your Choice Matter?

- 8 Essential Factors When Choosing a PCBA Manufacturer

- How to Evaluate PCBA Manufacturer Quality

- Red Flags to Avoid When Choosing a PCBA Manufacturer

- Industry Trends Affecting PCBA Manufacturing in 2025

- Your Complete PCBA Manufacturer Selection Checklist

- Frequently Asked Questions About PCBA Manufacturers

- Conclusion

What is PCBA Manufacturing and Why Does Your Choice Matter?

PCBA (Printed Circuit Board Assembly) manufacturing involves mounting electronic components onto printed circuit boards to create functional electronic devices. Therefore, your choice of PCBA manufacturer directly impacts your product’s quality, reliability, and market success.

Modern SMT production line with automated component placement

Advanced quality control testing with AOI inspection

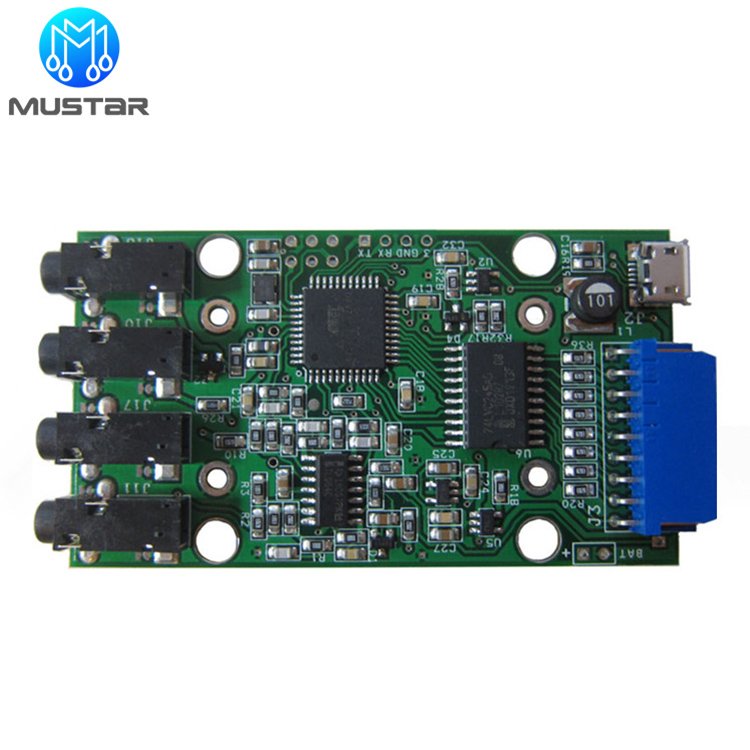

Finished PCBA

Moreover, a reliable PCBA manufacturer ensures your products meet industry standards while maintaining cost-effectiveness. Additionally, they provide technical expertise that can improve your design and reduce manufacturing risks.

8 Essential Factors When Choosing a PCBA Manufacturer

When selecting a PCBA manufacturer, you need to evaluate multiple factors systematically. Furthermore, each factor plays a crucial role in determining your project’s success and long-term partnership quality.

1. Experience and Industry Expertise

First and foremost, look for manufacturers with extensive experience in your specific industry. For instance, automotive PCBA requires different expertise than medical device manufacturing. Additionally, experienced manufacturers understand common challenges and can provide valuable design feedback.

“A manufacturer with 25+ years of experience has likely encountered and solved most manufacturing challenges you might face. This experience translates directly into fewer delays and higher success rates for your projects.”

Furthermore, industry expertise means understanding specific regulations and standards. For example, medical PCBA manufacturers must understand FDA regulations, while automotive manufacturers need knowledge of IATF 16949 standards.

2. Critical Certifications and Quality Standards

Next, verify that your potential PCBA manufacturer holds relevant industry certifications. These certifications demonstrate their commitment to quality and compliance with international standards.

| Certification | Purpose | Industry Application |

|---|---|---|

| ISO 9001 | Quality management systems | All industries |

| IPC-A-610 | Electronic assembly standards | Electronics manufacturing |

| ISO 13485 | Medical device quality systems | Medical electronics |

| IATF 16949 | Automotive quality management | Automotive electronics |

| RoHS & CE | Environmental compliance | European markets |

Additionally, look for manufacturers who maintain these certifications actively. Hence, ask for recent audit reports and renewal dates to ensure their compliance is current.

3. Manufacturing Capabilities and Advanced Technology

Subsequently, evaluate the manufacturer’s technical capabilities to handle your specific requirements. Modern PCBA manufacturing requires sophisticated equipment and advanced processes.

Advanced reflow oven with precise temperature control

3D X-ray inspection system for hidden solder joint analysis

Key manufacturing capabilities to verify include:

- PCB Complexity: Ability to handle 1-64 layer PCBs with advanced features

- Component Handling: Support for ultra-fine pitch components (01005, BGA, QFN)

- Production Volume: Scalability from prototypes to high-volume production

- Technology Support: HDI, flexible-rigid, high-frequency materials

- Assembly Types: SMT, through-hole, and mixed technology capabilities

Moreover, manufacturers with advanced capabilities can often suggest design improvements that reduce costs or improve reliability. Therefore, their technical expertise becomes an additional value proposition.

4. Quality Control and Testing Procedures

Quality control separates reliable PCBA manufacturers from average ones. Consequently, you should thoroughly investigate their quality processes and testing procedures.

| Quality Metric | Industry Standard | What It Measures |

|---|---|---|

| First Pass Yield (FPY) | >95% | Percentage of units passing initial testing |

| Defect Rate | <50 PPM | Defects per million opportunities |

| Return Rate | <0.5% | Percentage of products returned due to defects |

| MTBF (Mean Time Between Failures) | >100,000 hours | Product reliability measurement |

Furthermore, reliable manufacturers use comprehensive testing methods including:

- In-Circuit Testing (ICT): Verifies component placement and values

- Functional Circuit Testing (FCT): Tests actual circuit operation

- Automated Optical Inspection (AOI): Detects visual defects

- 3D Solder Paste Inspection (SPI): Ensures proper solder application

- X-Ray Testing: Identifies hidden solder joint issues

Additionally, ask about their continuous improvement processes. For example, manufacturers using Lean Six Sigma methodology typically achieve better quality outcomes.

5. Cost Transparency and Pricing Structure

Transparent pricing is essential for budget planning and avoiding unexpected costs. However, the lowest price doesn’t always mean the best value when choosing a PCBA manufacturer.

💡 Pro Tip: Understanding PCBA Pricing Components

A detailed quote should include: PCB fabrication costs, component costs, assembly fees, testing charges, tooling costs, and shipping expenses. Beware of quotes that seem too low—they often have hidden costs.

When evaluating pricing, consider these factors:

- Component Sourcing: Access to genuine components at competitive prices

- Volume Discounts: Pricing scalability for different order quantities

- Engineering Support: Design for manufacturability (DFM) feedback included

- Quality Costs: Testing and inspection services

- Lead Time Options: Rush order capabilities and associated costs

Moreover, reliable manufacturers provide detailed cost breakdowns and explain any price variations. Thus, you can make informed decisions about design trade-offs.

6. Communication and Customer Support

Effective communication prevents misunderstandings and keeps projects on track. Therefore, evaluate the manufacturer’s communication capabilities early in your selection process.

“Poor communication is the #1 cause of PCBA project delays and quality issues. A manufacturer who responds quickly and clearly to your questions will likely handle your production with the same attention to detail.”

Key communication factors include:

- Language Proficiency: Clear English communication for international clients

- Response Time: Quick replies to emails and technical questions

- Technical Expertise: Engineering support for design discussions

- Project Management: Regular updates on production status

- Time Zone Compatibility: Overlapping business hours for real-time communication

Additionally, test their communication during the quotation process. Consequently, their responsiveness and clarity will give you insight into future working relationships.

7. Location and Logistics Considerations

Geographic location affects shipping costs, delivery times, and communication ease. However, don’t automatically assume that closer means better for PCBA manufacturing.

Consider these location-related factors:

- Shipping Costs: Impact on total project costs

- Delivery Speed: Standard and expedited shipping options

- Supply Chain Access: Proximity to component suppliers

- Regulatory Environment: Trade policies and tariff implications

- Quality Infrastructure: Local testing and certification capabilities

Furthermore, many successful companies work with manufacturers in China, where established supply chains and advanced capabilities often offset shipping considerations. For instance, China’s electronics manufacturing ecosystem provides comprehensive solutions.

8. Value-Added Services and Turnkey Solutions

Finally, consider manufacturers who offer comprehensive services beyond basic assembly. These value-added services can simplify your supply chain and reduce management overhead.

Valuable additional services include:

- Design for Manufacturing (DFM): Optimization recommendations

- Component Sourcing: Global supplier network management

- Inventory Management: Just-in-time delivery programs

- Enclosure Assembly: Complete product fulfillment

- Regulatory Support: Compliance testing and documentation

- After-Sales Support: Field failure analysis and improvements

Moreover, turnkey solutions reduce your vendor management complexity while ensuring better integration between different manufacturing stages.

How to Evaluate PCBA Manufacturer Quality (Step-by-Step)

Systematic evaluation ensures you choose the right PCBA manufacturer for your needs. Therefore, follow this step-by-step process to make an informed decision.

📋 PCBA Manufacturer Evaluation Checklist

Phase 1: Initial Research

- ☐ Review company website and capabilities

- ☐ Check years of experience and industry focus

- ☐ Verify certifications and compliance standards

- ☐ Read customer testimonials and case studies

Phase 2: Technical Assessment

- ☐ Request detailed capability documentation

- ☐ Evaluate equipment list and technology level

- ☐ Review quality control processes and metrics

- ☐ Assess design support and engineering expertise

Phase 3: Business Evaluation

- ☐ Obtain detailed pricing breakdown

- ☐ Confirm lead times and delivery schedules

- ☐ Test communication responsiveness

- ☐ Review terms and conditions

Phase 4: Final Verification

- ☐ Request and evaluate sample work

- ☐ Conduct facility audit (virtual or in-person)

- ☐ Check references from current clients

- ☐ Negotiate trial production agreement

Additionally, consider starting with a small trial order to evaluate their actual performance before committing to larger volumes. This approach minimizes risk while providing real-world experience.

Red Flags to Avoid When Choosing a PCBA Manufacturer

Recognizing warning signs early can save you time, money, and frustration. Therefore, watch for these red flags during your manufacturer selection process.

🚩 Critical Warning Signs

Pricing Red Flags:

- Quotes significantly below market rates without explanation

- Reluctance to provide detailed cost breakdowns

- Hidden fees appearing after initial agreements

- No clear policy on component price fluctuations

Communication Red Flags:

- Slow response times (>24 hours for initial inquiries)

- Vague answers to technical questions

- No dedicated project manager or point of contact

- Language barriers affecting technical discussions

Quality Red Flags:

- Inability to provide quality metrics or certifications

- No formal quality control processes

- Reluctance to allow facility inspections

- Limited or no testing capabilities

Furthermore, trust your instincts. If something feels wrong during initial interactions, it’s likely to become a bigger problem during production. Therefore, take time to find the right partner rather than rushing into a decision.

Industry Trends Affecting PCBA Manufacturing in 2025

Understanding current industry trends helps you choose a PCBA manufacturer who can adapt to future requirements. Consequently, these trends are shaping manufacturing capabilities and focus areas.

Key Technology Drivers:

Artificial Intelligence Integration: AI applications require high-performance computing PCBAs with advanced thermal management. Moreover, manufacturers must understand AI chip packaging and cooling requirements.

Electric Vehicle Growth: The automotive PCB market reached $74.6 billion in 2023, driven by EV adoption. Additionally, automotive PCBA requires specialized knowledge of high-voltage systems and automotive-grade components.

5G Infrastructure Expansion: 5G technology demands high-frequency PCBs with specialized materials and precise manufacturing tolerances. Furthermore, manufacturers need expertise in RF design and testing.

IoT Device Proliferation: Internet of Things devices require compact, power-efficient PCBAs with wireless connectivity. Consequently, manufacturers must understand miniaturization and power management techniques.

For more insights on industry trends, refer to IPC’s industry reports and SMTA technical resources.

Your Complete PCBA Manufacturer Selection Checklist

Use this comprehensive checklist to ensure you don’t miss any critical factors when choosing your PCBA manufacturer. Therefore, print this section or bookmark it for easy reference during your evaluation process.

✅ Final Selection Checklist

| Evaluation Criteria | ✓ Check | Notes |

|---|---|---|

| Company has 15+ years experience | ☐ | Years: ___ |

| Holds relevant industry certifications | ☐ | Certs: ___ |

| Can handle your PCB complexity requirements | ☐ | Max layers: ___ |

| Provides transparent, detailed pricing | ☐ | Quote received: ___ |

| Offers comprehensive quality testing | ☐ | Testing types: ___ |

| Demonstrates responsive communication | ☐ | Response time: ___ |

| Provides customer references | ☐ | References: ___ |

| Offers value-added services | ☐ | Services: ___ |

Frequently Asked Questions About PCBA Manufacturers

These commonly asked questions provide additional insights to help you make the best decision when choosing a PCBA manufacturer.

What certifications should a reliable PCBA manufacturer have?

A reliable PCBA manufacturer should hold industry-recognized certifications such as ISO 9001 for quality management, IPC-A-610 for electronic assembly standards, and industry-specific certifications like ISO 13485 for medical electronics or IATF 16949 for automotive electronics. Additionally, environmental certifications like RoHS and REACH compliance are essential for global market access.

How can I evaluate the quality of a PCBA manufacturer?

Evaluate quality through key metrics like First Pass Yield (FPY) above 95%, defect rates below 50 PPM, and return rates under 0.5%. Furthermore, assess their quality control processes, including multiple testing stages, root cause analysis procedures, and continuous improvement programs. Moreover, customer testimonials and third-party audits provide valuable quality insights.

What manufacturing capabilities should I look for in a PCBA supplier?

Look for manufacturers with advanced equipment capable of producing complex PCBAs, such as HDI (High-Density Interconnect) boards, fine-pitch components down to 01005 size, and multilayer boards up to 64 layers. Additionally, they should have scalable production capacity, robust supply chain management, and the ability to handle both SMT and through-hole technologies.

How important is communication when choosing a PCBA manufacturer?

Effective communication is absolutely critical for project success. A reliable manufacturer should provide knowledgeable and responsive contacts who understand your requirements and can provide timely updates. Moreover, poor communication often leads to misunderstandings, delays, and quality issues. Therefore, test their communication during the quotation process.

What are typical lead times and cost considerations for PCBA manufacturing?

Lead times vary based on complexity and volume but typically range from 2-4 weeks for prototypes and 4-8 weeks for production runs. However, costs should be competitive while maintaining quality standards. Additionally, transparent pricing should include all components: PCB fabrication, components, assembly, testing, and shipping. Furthermore, beware of quotes that seem unusually low, as they often have hidden costs.

Should I choose a local or overseas PCBA manufacturer?

The choice depends on your priorities. Local manufacturers offer easier communication and faster shipping but may have higher costs. Conversely, overseas manufacturers (particularly in China) often provide cost advantages and advanced capabilities, though with longer shipping times. However, many successful companies work with overseas manufacturers who offer excellent communication and quality. Therefore, evaluate each manufacturer individually rather than making location-based assumptions.

Conclusion: Making the Right Choice for Your PCBA Manufacturing Partner

Choosing the right PCBA manufacturer is one of the most important decisions for your product’s success. Throughout this guide, we’ve covered the eight essential factors that determine manufacturer reliability: experience, certifications, capabilities, quality control, pricing transparency, communication, location, and value-added services.

Remember that the lowest price doesn’t always represent the best value. Instead, focus on finding a manufacturer who demonstrates consistent quality, responsive communication, and the technical expertise to support your specific requirements. Additionally, start with a trial order to verify their capabilities before committing to larger volumes.

The global PCB market’s growth to $85.4 billion in 2025 reflects the increasing demand for reliable electronics manufacturing. Therefore, partnering with an experienced, certified manufacturer positions your products for success in this expanding market.

Ready to Find Your Ideal PCBA Manufacturing Partner?

Mustar has been delivering high-precision PCBA solutions for over 25 years, serving automotive, medical, and industrial clients worldwide.

✓ ISO 9001, ISO 13485, IATF 16949 Certified

✓ 1-64 Layer PCB Capabilities

✓ 95%+ First Pass Yield

✓ 4-8 Hour Sample Turnaround

✓ Global Component Sourcing Network

Get Your Free Quote Today!

Contact our engineering team to discuss your PCBA requirements and receive a detailed quote within 24 hours.

📧 Email: sales@pcbamustar.com | 📞 Phone: +86 136 8883 2535

🏭 Factory: Shenzhen, China | 🌐 Website: pcbamustar.com

Additional Resources:

Mustar projects: