PCB Assembly Methods at a Glance

Contents

- What is PCB Assembly? (Quick Overview)

- Critical Design Requirements for Smart Grid PCBs

- Step-by-Step PCB Assembly Process

- Essential Tools for PCB Assembly

- Quality Control and Testing Methods

- Common PCB Assembly Challenges (and Solutions)

- PCB Assembly Industry Insights

- Professional vs. DIY PCB Assembly: Which to Choose?

- Ready to Get Your PCB Assembled Professionally?

What is PCB Assembly? (Quick Overview)

PCB assembly, also known as PCBA, is the process of soldering electronic components onto a bare printed circuit board. Moreover, this process transforms a simple PCB into a functional electronic device. Additionally, the assembly involves placing components like resistors, capacitors, and integrated circuits in precise locations.

Furthermore, IPC standards govern the quality requirements for PCB assembly. Consequently, proper assembly ensures your electronic device works reliably and safely. Therefore, understanding how to assemble a PCB board is crucial for anyone in electronics manufacturing.

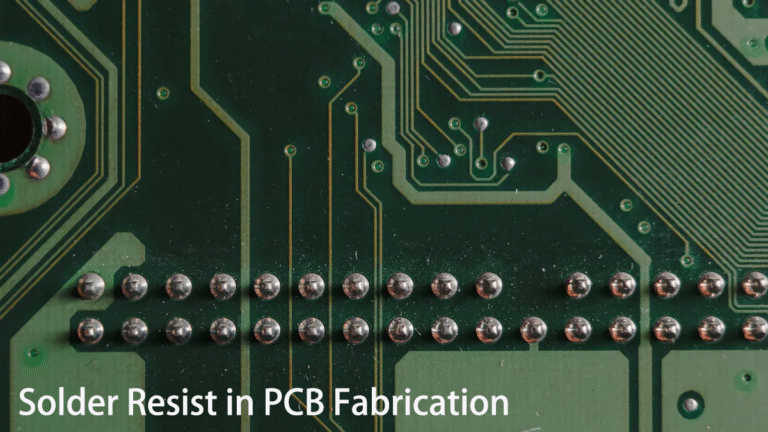

PCB Assembly Methods Explained

Surface Mount Technology (SMT)

Surface Mount Technology represents the most common method for PCB assembly today. Additionally, SMT components mount directly onto the board’s surface without drilling holes. Furthermore, this method enables high-density component placement and faster assembly speeds.

Moreover, SMT assembly uses automated pick-and-place machines that can handle up to 50,000 components per hour. Consequently, this method is perfect for mass production and compact electronic devices. Therefore, most smartphones, tablets, and modern electronics use SMT assembly.

Through-Hole Technology (THT)

Through-hole technology involves inserting component leads through drilled holes in the PCB. Additionally, the leads are then soldered on the opposite side of the board. Furthermore, this method provides stronger mechanical connections compared to SMT.

Moreover, THT assembly is ideal for components that experience mechanical stress. Consequently, power connectors, transformers, and large capacitors often use through-hole mounting. Therefore, beginners find THT easier to work with due to larger component sizes.

Hybrid Assembly

Hybrid assembly combines both SMT and THT techniques on the same PCB. Additionally, this method allows designers to optimize component placement for different requirements. Furthermore, complex electronic devices often require hybrid assembly for optimal performance.

Moreover, hybrid assembly enables the use of both compact SMT components and robust through-hole components. Consequently, this approach provides the best of both worlds. Therefore, professional PCB assembly services often recommend hybrid solutions for complex projects.

Step-by-Step PCB Assembly Process

Step 1: Apply Solder Paste

The PCB assembly process begins with applying solder paste using a stencil. Additionally, the paste contains tiny solder balls suspended in flux. Furthermore, precise paste application ensures proper component attachment during reflow soldering.

Moreover, the stencil thickness determines the paste volume. Consequently, different component types require specific paste amounts. Therefore, professional manufacturers use automated paste dispensing systems for consistency.

Step 2: Component Placement

Component placement involves positioning electronic parts onto the solder paste. Additionally, this step requires extreme precision to ensure proper connections. Furthermore, automated pick-and-place machines achieve accuracy within ±0.05mm.

Moreover, component orientation and polarity must be correct during placement. Consequently, incorrect placement can cause circuit failures. Therefore, professional assembly services use vision systems to verify component placement accuracy.

Step 3: Reflow Soldering

Reflow soldering melts the solder paste to form permanent connections. Additionally, the PCB passes through a reflow oven with controlled temperature zones. Furthermore, proper thermal profiling ensures reliable solder joints.

Moreover, different solder alloys require specific temperature profiles. Consequently, lead-free soldering operates at higher temperatures than traditional lead-based solders. Therefore, proper temperature control prevents component damage and ensures joint quality.

Step 4: Inspection and Quality Control

Quality inspection verifies proper component placement and solder joint quality. Additionally, multiple inspection methods ensure assembly reliability. Furthermore, automated optical inspection (AOI) systems check for defects quickly and accurately.

Moreover, X-ray inspection examines hidden solder joints under components like BGAs. Consequently, comprehensive inspection catches defects before they reach customers. Therefore, professional manufacturers implement multiple inspection stages throughout the assembly process.

Step 5: Through-Hole Component Assembly

If the design includes through-hole components, they are inserted and soldered after SMT assembly. Additionally, wave soldering or selective soldering techniques attach these components. Furthermore, manual soldering may be required for complex or delicate parts.

Step 6: Final Testing

Final testing verifies the assembled PCB functions correctly. Additionally, in-circuit testing (ICT) checks electrical connections and component values. Furthermore, functional testing simulates real-world operating conditions.

Moreover, boundary scan testing verifies complex digital circuits. Consequently, comprehensive testing ensures product reliability. Therefore, proper testing protocols prevent field failures and warranty claims.

Essential Tools for PCB Assembly

The right tools make PCB assembly more efficient and reliable. Additionally, tool selection depends on assembly complexity and volume requirements. Furthermore, professional-grade equipment ensures consistent results.

Professional Assembly Tools

- Pick-and-place machines – Automated component placement

- Reflow ovens – Controlled soldering environment

- Stencil printers – Precise solder paste application

- AOI systems – Automated quality inspection

- X-ray machines – Hidden joint inspection

DIY Assembly Tools

- Soldering iron – Temperature-controlled preferred

- Solder paste – Lead-free recommended

- Tweezers – Precision component handling

- Magnification – Stereo microscope or magnifying glass

- Hot air gun – Reflow soldering for small batches

Moreover, proper ventilation and safety equipment are essential. Consequently, fume extraction systems protect workers from harmful vapors. Therefore, workplace safety standards must be followed during assembly operations.

Quality Control and Testing Methods

Quality control ensures every assembled PCB meets specifications. Additionally, multiple testing stages catch defects early in the process. Furthermore, statistical process control helps maintain consistent quality levels.

Visual Inspection Techniques

- Manual inspection – Human operators check for obvious defects

- Magnified inspection – Detailed examination of solder joints

- Automated Optical Inspection (AOI) – Computer vision systems detect anomalies

Advanced Testing Methods

- X-ray inspection – Examines hidden solder joints

- 3D Solder Paste Inspection (SPI) – Verifies paste volume and placement

- In-Circuit Testing (ICT) – Electrical parameter verification

- Functional Circuit Testing (FCT) – Real-world operation simulation

Moreover, IPC-A-610 standards define acceptable quality criteria for electronic assemblies. Consequently, adherence to these standards ensures industry-standard quality. Therefore, professional assembly services maintain certification to these standards.

Common PCB Assembly Challenges (and Solutions)

Understanding assembly challenges helps prevent costly mistakes and rework. Additionally, proper planning and execution avoid common pitfalls. Furthermore, experienced manufacturers develop solutions for complex assembly issues.

Solder Paste Application Issues

- Challenge: Uneven paste distribution

- Solution: Regular stencil cleaning and proper squeegee pressure

- Prevention: Use automated paste inspection systems

Component Misplacement Problems

- Challenge: Components placed incorrectly or rotated

- Solution: Vision-guided pick-and-place systems

- Prevention: Clear component orientation markings

Thermal Management Difficulties

- Challenge: Uneven heating causing solder joint defects

- Solution: Proper thermal profiling and oven maintenance

- Prevention: Design thermal balance into PCB layout

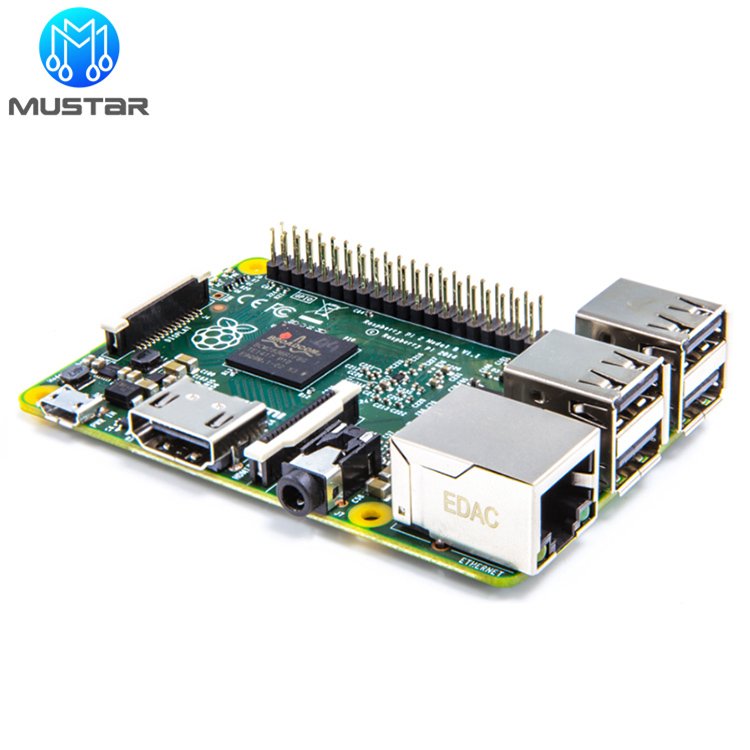

Moreover, component obsolescence can disrupt assembly schedules. Consequently, proactive component lifecycle management prevents supply disruptions. Therefore, experienced manufacturers like Mustar maintain relationships with over 200 global suppliers to ensure component availability.

PCB Assembly Industry Insights

The PCB assembly industry continues growing rapidly driven by digital transformation. Additionally, emerging technologies create new opportunities and challenges. Furthermore, understanding market trends helps make informed business decisions.

| Statistic | Value | Year |

|---|---|---|

| Global PCB Assembly Market | $90 billion | 2024 |

| Asia Pacific Market Share | Over 60% | 2025 |

| China PCB Market Share | 32.8% | 2024 |

| Projected HDI PCB Market Value | Nearly $40 billion | 2032 |

| Assembly Speed (parts/hour) | Up to 50,000 | Current |

Key Industry Trends

- Miniaturization: Smaller components require higher precision assembly

- AI Integration: Smart factory automation improves efficiency

- Environmental Compliance: RoHS and REACH regulations drive material changes

- 5G Technology: High-frequency applications demand specialized assembly techniques

Moreover, market research indicates continued growth in automotive and medical electronics. Consequently, assembly providers must adapt to stricter quality requirements. Therefore, certifications like ISO13485 and IATF16949 become increasingly important.

Professional vs. DIY PCB Assembly: Which to Choose?

Choosing between professional and DIY assembly depends on multiple factors including complexity, volume, and budget. Additionally, each approach has distinct advantages and limitations. Furthermore, understanding these differences helps make the right decision for your project.

When to Choose Professional Assembly

- High volume production (>100 units)

- Complex designs with fine-pitch components

- Critical applications requiring reliability

- Tight deadlines and fast turnaround

- Limited assembly experience or equipment

When DIY Assembly Makes Sense

- Prototyping and learning projects

- Simple through-hole designs

- Very small quantities (1-10 units)

- Budget constraints for hobby projects

- Educational purposes and skill development

Professional Assembly Advantages

Professional assembly services like Mustar offer comprehensive solutions including component sourcing, assembly, testing, and quality assurance. Additionally, their 25+ years of experience ensures reliable results. Furthermore, advanced equipment and certified processes minimize defect rates.

“Professional assembly services can achieve defect rates below 100 PPM (parts per million), while manual assembly typically ranges from 1,000-10,000 PPM.” – Assembly Magazine

Moreover, professional services provide comprehensive testing including ICT, FCT, and burn-in testing. Consequently, products meet stringent quality standards for automotive, medical, and industrial applications. Therefore, the investment in professional assembly often pays for itself through reduced field failures and warranty claims.

Cost-Benefit Analysis

While professional assembly has higher upfront costs, it offers significant value through reduced risk and faster time-to-market. Additionally, economies of scale make professional assembly cost-effective for medium to high volumes. Furthermore, the comprehensive service model eliminates the need for multiple suppliers.

Moreover, professional assemblers like Mustar maintain relationships with over 200 global suppliers, ensuring competitive component pricing. Consequently, total project costs often favor professional assembly even for moderate volumes. Therefore, a detailed cost analysis should include factors beyond just assembly fees.

Ready to Get Your PCB Assembled Professionally?

Mustar has been a trusted PCB assembly partner for over 25 years, serving automotive, medical, industrial, and consumer electronics companies worldwide. With our state-of-the-art facility, certified processes, and experienced team, we deliver high-quality assemblies on time and within budget.

Why Choose Mustar for Your PCB Assembly?

- ✓ Comprehensive one-stop solution from PCB fabrication to final testing

- ✓ Advanced manufacturing capabilities supporting 1-64 layer PCBs

- ✓ Industry certifications including ISO9001, ISO13485, IATF16949

- ✓ Fast turnaround with samples in 4-8 hours

- ✓ Global supplier network ensuring component availability

- ✓ Dedicated automotive and medical production lines

Don’t let assembly challenges delay your product launch. Contact our expert team today for a free quote and discover how professional PCB assembly can accelerate your project success.

Get Free Quote Now →