How Much Does PCB Assembly Cost?

Quick Answer: PCB assembly costs typically range from $10 to over $100 per board. However, the final price depends on several key factors including board complexity, component types, and order volume. Small prototype runs cost $30-$100+ per board, while large production runs can reduce costs to $5-$20 per board.

Contents

- Quick Answer: PCB Assembly Cost Overview

- What Is PCB Assembly and Why Costs Vary So Much?

- The 6 Key Factors That Drive PCB Assembly Costs

- Real PCB Assembly Costs

- How Order Volume Dramatically Changes Your Costs

- Hidden Costs You Need to Budget For

- How to Get Accurate PCB Assembly Quotes

- 5 Smart Ways to Reduce Your PCB Assembly Costs

- Why Mustar Delivers Superior Value for PCB Assembly

- Conclusion

Quick Answer: PCB Assembly Cost Overview

How Much Does PCB Assembly Cost?When you’re planning your next electronics project, understanding PCB assembly costs is crucial for budgeting. Therefore, we’ve compiled real industry data to give you immediate answers.

| PCB Specification | Quantity | Cost per PCB (USD) | Total Cost (USD) |

|---|---|---|---|

| Simple 2-layer PCB (10×10 cm) | 50 | $1 – $5 | $50 – $250 |

| PCB Assembly (100 in² per PCB) | 50 | $0.02 – $0.05 per in² | $100 – $250 |

| Mid-complexity Assembly | 100 | $30 – $70 | $3,000 – $7,000 |

| High-volume Production | 1000+ | $5 – $20 | $5,000 – $20,000 |

Most importantly, these costs include both PCB manufacturing and component assembly. Additionally, setup fees and testing can add 20-40% to your total project cost.

What Is PCB Assembly and Why Costs Vary So Much?

PCB assembly is the process of mounting electronic components onto printed circuit boards. Furthermore, this process involves multiple steps that directly impact your final costs.

The assembly process includes several key steps:

- Component sourcing: Finding and purchasing all required parts

- PCB preparation: Applying solder paste and positioning components

- Surface Mount Technology (SMT): Automated placement of small components

- Through-hole assembly: Manual insertion of larger components

- Quality testing: Ensuring proper functionality and reliability

Consequently, costs vary dramatically because each step requires different levels of expertise, equipment, and time investment.

The 6 Key Factors That Drive PCB Assembly Costs

Understanding these factors helps you make smarter decisions about your PCB assembly cost budget. Moreover, each factor can significantly impact your final pricing.

1. Board Complexity and Design

Complex designs with multiple layers, dense component placement, and advanced features cost more to assemble. For instance, a simple 2-layer board costs much less than a 12-layer board with impedance control.

2. Component Types and Availability

Specialized components like high-frequency chips or automotive-grade parts increase costs. Additionally, component shortages can drive prices up significantly.

3. Production Volume

Higher volumes spread setup costs across more units. Therefore, ordering 1000 units typically costs much less per board than ordering 50 units.

4. Labor Requirements

Hand-soldered components and complex assembly processes require skilled technicians. Consequently, labor-intensive boards cost more to assemble.

5. Testing and Quality Standards

Medical and automotive applications require extensive testing. Furthermore, certifications like ISO 13485 add to assembly costs.

6. Geographic Location

Assembly costs vary by region, with Asian manufacturers typically offering competitive pricing. However, shipping and lead times must also be considered.

Real PCB Assembly Costs: Industry Data and Examples

Based on current market data, here are realistic PCB assembly cost examples for different project types:

| Project Type | Board Size | Components | Quantity | Cost per Board |

|---|---|---|---|---|

| Simple IoT Device | 5×5 cm | 50-100 | 100 | $15 – $25 |

| Consumer Electronics | 10×8 cm | 200-500 | 500 | $25 – $45 |

| Industrial Control | 15×12 cm | 500-1000 | 200 | $60 – $90 |

| Automotive Module | 12×10 cm | 300-600 | 1000 | $35 – $55 |

These examples include both PCB manufacturing and assembly costs. However, additional services like programming or testing may increase the final price.

How Order Volume Dramatically Changes Your Costs

Volume has the biggest impact on your PCB assembly cost per unit. Therefore, understanding economies of scale helps you plan better budgets.

Prototype Quantities (1-50 units)

Small runs face several cost challenges:

- Setup fees spread across fewer units

- Minimum order quantities for components

- Limited automation benefits

- Higher per-unit labor costs

Consequently, prototype PCB assembly typically costs $30-$100+ per board.

Medium Production (100-500 units)

Medium volumes start showing cost benefits:

- Setup costs become more manageable

- Some component quantity discounts apply

- More efficient assembly processes

Therefore, costs typically drop to $20-$50 per board for medium complexity designs.

High Volume Production (1000+ units)

Large volumes unlock significant savings:

- Maximum component purchasing power

- Fully automated assembly processes

- Lowest per-unit setup costs

- Optimized manufacturing workflows

As a result, high-volume PCB assembly costs can drop to $5-$20 per board.

Hidden Costs You Need to Budget For

Many customers focus only on assembly costs but forget additional expenses. Moreover, these hidden costs can add 20-40% to your total project budget.

Setup and Engineering Fees

Most manufacturers charge one-time setup fees ranging from $200-$1,500. Additionally, design for manufacturing (DFM) reviews may cost extra.

Testing and Quality Control

Essential testing services include:

- In-Circuit Testing (ICT): $0.50-$2 per board

- Functional Testing: $1-$5 per board

- Automated Optical Inspection (AOI): $0.25-$1 per board

- X-ray Inspection: $0.50-$2 per board

Certifications and Compliance

Industry certifications add costs but ensure quality:

- IATF 16949 (Automotive): $500-$2,000 setup

- ISO 13485 (Medical): $300-$1,500 setup

- RoHS compliance: $100-$500 testing

Packaging and Shipping

Protective packaging and shipping costs vary by destination. Furthermore, expedited shipping can significantly increase expenses.

How to Get Accurate PCB Assembly Quotes (Step-by-Step)

Getting precise PCB assembly cost quotes requires proper preparation. Therefore, follow these steps to ensure accurate pricing.

Step 1: Prepare Complete Design Files

Manufacturers need these essential files:

- Gerber files (latest RS-274X format)

- Drill files (Excellon format)

- Pick and place files

- Assembly drawings

- Fabrication notes

Step 2: Create a Detailed Bill of Materials (BOM)

Your BOM should include:

- Part numbers and descriptions

- Quantities required

- Preferred manufacturers

- Alternative part options

- Special handling requirements

Step 3: Specify Your Requirements

Clearly communicate:

- Target quantities and delivery dates

- Quality standards and certifications

- Testing requirements

- Packaging preferences

- Budget constraints

Step 4: Request Multiple Quotes

Compare quotes from 3-5 reputable manufacturers. Additionally, consider factors beyond just price, such as quality track record and delivery reliability.

5 Smart Ways to Reduce Your PCB Assembly Costs

How Much Does PCB Assembly Cost?Implementing these strategies can significantly lower your PCB assembly cost without compromising quality. Moreover, small design changes can lead to substantial savings.

1. Optimize Your PCB Design

Smart design choices reduce assembly complexity:

- Use standard component packages when possible

- Minimize the number of unique components

- Design for automated assembly processes

- Avoid ultra-fine pitch components unless necessary

2. Choose Components Strategically

Component selection dramatically impacts costs:

- Select readily available parts to avoid sourcing delays

- Use multiple approved vendors for critical components

- Consider functional equivalents that cost less

- Avoid obsolete or end-of-life components

3. Plan Your Volumes Wisely

Volume planning can optimize your budget:

- Consider ordering larger quantities to hit price breaks

- Plan for future orders to negotiate better rates

- Balance inventory costs against assembly savings

4. Simplify Testing Requirements

Testing costs add up quickly, so:

- Design for testability from the beginning

- Use boundary scan where appropriate

- Minimize custom test fixture requirements

- Consider statistical sampling for large volumes

5. Build Strong Manufacturer Relationships

Long-term partnerships offer advantages:

- Better pricing for repeat customers

- Priority scheduling during busy periods

- Access to engineering expertise

- Flexible payment terms

Why Mustar Delivers Superior Value for PCB Assembly

When considering PCB assembly cost options, Mustar stands out as a trusted partner with over 25 years of experience. Furthermore, our comprehensive approach ensures both competitive pricing and exceptional quality.

Comprehensive Cost Optimization

Mustar’s integrated approach reduces your total PCB assembly cost:

- One-stop solution: From PCB fabrication to final assembly under one roof

- Component sourcing expertise: Over 200 global suppliers ensure competitive pricing

- Volume flexibility: Efficient handling of both prototypes and mass production

- Fast turnaround: PCB samples in 4-8 hours reduces development costs

Advanced Manufacturing Capabilities

Our technology investments deliver cost-effective solutions:

- 20 SMT lines with 6 dedicated automotive/medical lines

- Capability for 1-64 layer PCBs with advanced technologies

- Ultra-fine pitch assembly including 01005 components

- Comprehensive testing with ICT, FCT, 3D SPI, and X-ray

Industry Certifications Reduce Risk

Our certifications ensure compliance without additional costs:

- IATF 16949 for automotive applications

- ISO 13485 for medical device assembly

- ISO 9001, ISO 14001, CE, RoHS, and UL compliance

Proven Track Record

Mustar’s experience translates to cost savings for you:

- Over 500 types of automotive PCBAs produced

- Trusted by 100+ automotive electronics enterprises

- 25+ years of continuous innovation and improvement

- 600+ experienced staff including 50+ sourcing engineers

Conclusion: Make Smart PCB Assembly Cost Decisions

How Much Does PCB Assembly Cost?Understanding PCB assembly costs empowers you to make informed decisions for your electronics projects. As we’ve shown, costs typically range from $10-$100+ per board, depending on complexity, volume, and requirements.

Key takeaways for managing your PCB assembly budget:

- Volume dramatically impacts per-unit costs

- Design optimization can reduce expenses by 20-40%

- Hidden costs like testing and setup fees matter

- Choosing the right manufacturing partner saves money long-term

Most importantly, working with an experienced manufacturer like Mustar ensures you get competitive pricing without sacrificing quality. Our 25+ years of expertise, comprehensive certifications, and integrated approach deliver exceptional value for your PCB assembly needs.

Ready to Get Your PCB Assembly Quote?

Don’t let PCB assembly costs surprise you. Get a detailed, transparent quote from Mustar’s experienced team today. We’ll help you optimize your design and budget for maximum value.

✓ Fast 24-hour response ✓ DFM review included ✓ No hidden fees

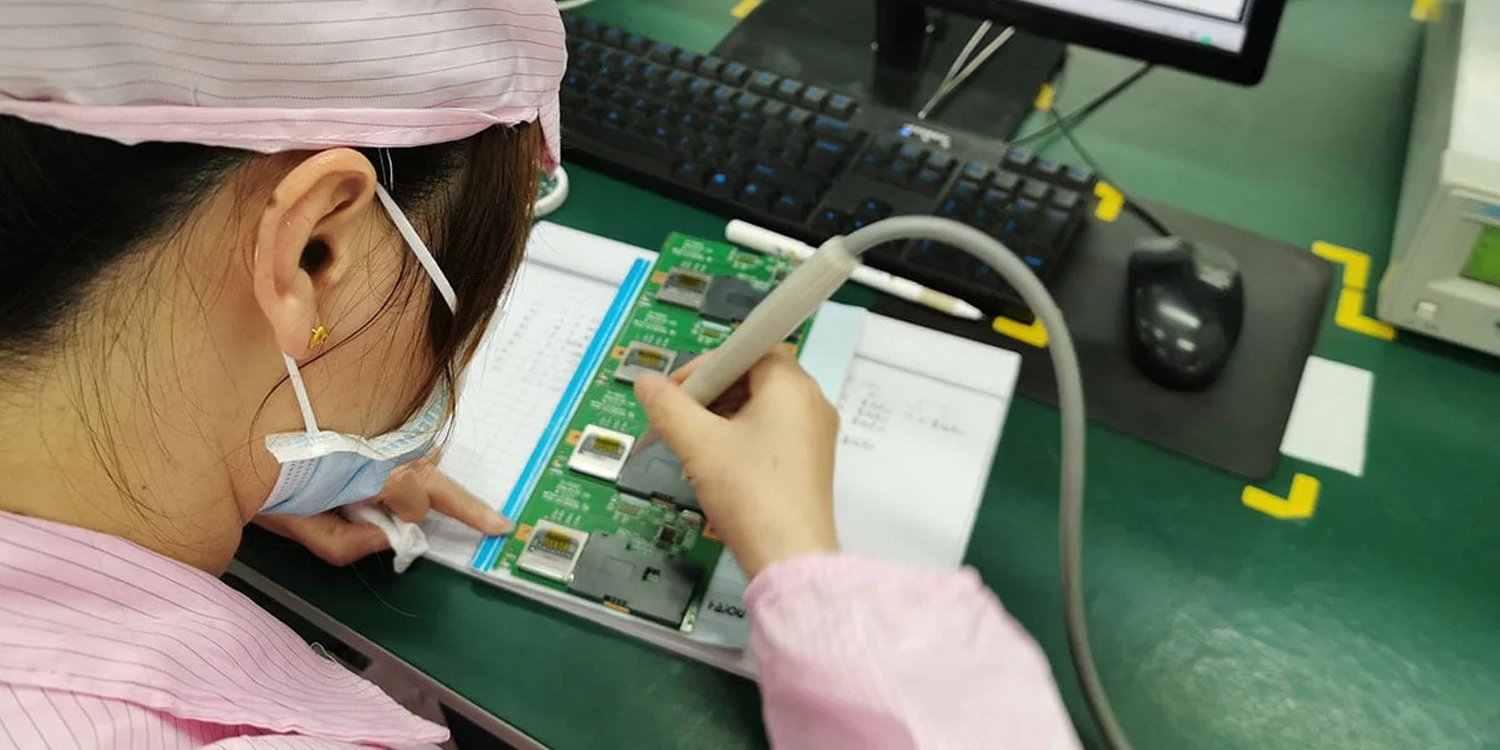

Mustar projects: