Quick Answer: PCB Layer Counts & Applications

| Layer Count | Typical Applications | Cost Level |

|---|---|---|

| 1-2 Layers | Simple electronics, LED boards, power supplies | Low |

| 4-6 Layers | Smartphones, medical devices, automotive | Medium |

| 8-12 Layers | Graphics cards, servers, aerospace | High |

| 20+ Layers | Telecom, military, supercomputers | Very High |

Quick Answer: PCBs can have anywhere from 1 to 100+ layers, with the world record being 129 layers. However, most commercial PCBs use between 4-12 layers for the best balance of performance and cost.

Contents

- What Is a PCB Layer?

- How Many Layers Can a PCB Have?

- Most Common PCB Layer Counts

- PCB Layer Count by Industry & Application

- How to Choose the Right Number of Layers for Your Project

- Cost vs. Performance: What More Layers Mean

- Frequently Asked Questions

- Industry Trends & Future of PCB Layers

- Conclusion

What Is a PCB Layer?

Think of a PCB layer like a slice of bread in a sandwich. Each layer is a thin sheet that serves a specific purpose in your electronic circuit. Just as a sandwich has different ingredients between bread slices, a PCB has different materials between its layers.

A PCB layer consists of two main types of materials:

- Conductive layers – Usually made of copper, these carry electrical signals

- Insulating layers – Made of materials like fiberglass, these separate the conductive layers

When manufacturers stack these layers together, they create a multilayer PCB. Therefore, the more layers you add, the more complex circuits you can build in a smaller space.

How Many Layers Can a PCB Have? (The Complete Answer)

The short answer is: PCBs can theoretically have up to 100+ layers, but the practical limit depends on several factors including cost, manufacturing capability, and application requirements.

World Record: The highest number of layers ever achieved in a PCB is 129 layers, accomplished by a Japanese company in 2012. This remains the Guinness World Record for multilayer PCBs.

However, let’s break down the realistic numbers:

- Typical range: Most commercial PCBs use between 4-12 layers

- High-end applications: 20-40 layers for specialized equipment

- Extreme cases: 50-100+ layers for military and aerospace applications

The reason for these limits comes down to manufacturing complexity and cost. As you add more layers, the PCB becomes harder to manufacture and significantly more expensive.

Most Common PCB Layer Counts (What You’ll Actually See)

In the real world, you’ll encounter certain layer counts much more frequently than others. Here’s what you need to know about the most common PCB layer configurations:

Single Layer PCBs (1 Layer)

These are the simplest and cheapest PCBs. You’ll find them in basic electronics like LED strips, simple switches, and radio circuits. Since they only have one conductive layer, all components must fit on one side.

Double Layer PCBs (2 Layers)

Also called double-sided PCBs, these have copper on both sides. They’re perfect for more complex circuits that need more space. Examples include power supplies, amplifiers, and HVAC systems.

4-Layer PCBs

This is where things get interesting. 4-layer PCBs are extremely popular because they offer excellent signal integrity and EMI shielding. You’ll find them in smartphones, tablets, and most consumer electronics.

6-8 Layer PCBs

These are used for more demanding applications like medical devices, networking equipment, and automotive electronics. They provide better power distribution and signal routing.

Why Even Numbers?

Most multilayer PCBs have an even number of layers because it provides better mechanical balance. This reduces warping during manufacturing and improves reliability. While odd-layer PCBs are possible, they’re less common due to higher manufacturing risks.

PCB Layer Count by Industry & Application

Different industries have different requirements for PCB complexity. Here’s how various sectors typically use PCB layers:

| Industry | Typical Layer Count | Specific Applications |

|---|---|---|

| Consumer Electronics | 2-6 layers | Smartphones, tablets, gaming consoles |

| Automotive | 4-8 layers | Engine control units, infotainment systems |

| Medical | 6-12 layers | Ultrasound equipment, patient monitors |

| Telecommunications | 10-32 layers | 5G base stations, network routers |

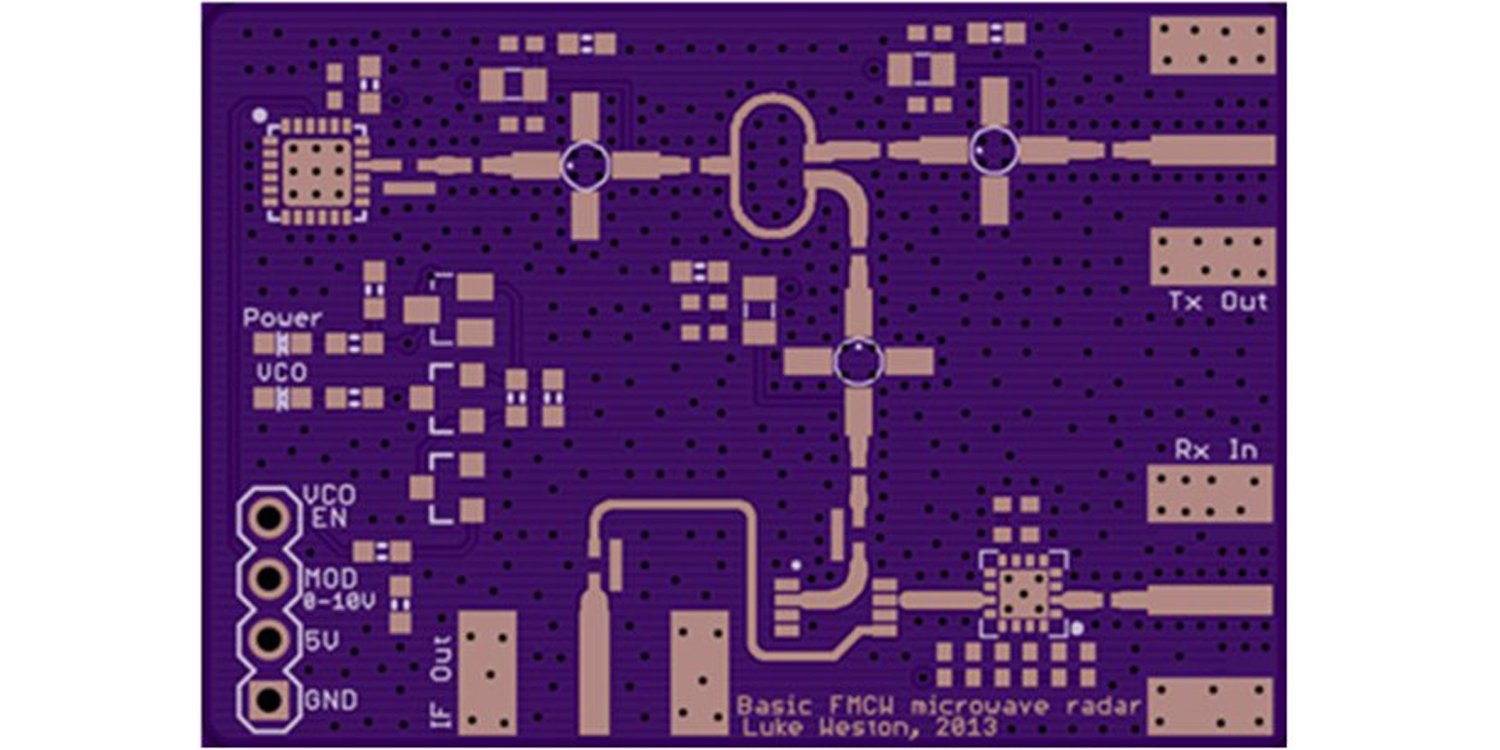

| Aerospace/Military | 20-100+ layers | Radar systems, satellite communications |

According to industry reports, the global PCB market is experiencing significant growth, with multilayer PCBs representing the largest segment due to increasing demand for compact, high-performance electronics.

How to Choose the Right Number of Layers for Your Project

Choosing the right number of PCB layers is crucial for your project’s success. Here’s a step-by-step guide to help you make the right decision:

Step 1: Analyze Your Circuit Complexity

- Component count: More components usually need more layers

- Signal types: Digital, analog, and power signals may need separation

- Trace density: How many connections do you need to make?

Step 2: Consider Performance Requirements

- Signal speed: High-speed signals need dedicated layers

- EMI/EMC compliance: More layers provide better shielding

- Power distribution: Complex circuits need dedicated power planes

Step 3: Evaluate Size Constraints

If your device must be compact, you’ll likely need more layers to fit everything. Conversely, if size isn’t critical, you might use fewer layers to save costs.

Step 4: Set Your Budget

Remember that each additional layer significantly increases manufacturing costs. Therefore, balance your performance needs with your budget constraints.

Pro Tip:

Start with the minimum number of layers that meet your requirements. You can always add layers later if needed, but removing them is much harder once you’ve committed to a design.

Cost vs. Performance: What More Layers Mean

Understanding the cost-performance relationship is essential when deciding on PCB layer count. Here’s what happens as you add more layers:

Performance Benefits of More Layers

- Better signal integrity: Dedicated signal and ground planes reduce interference

- Improved EMI shielding: More ground planes provide better electromagnetic shielding

- Enhanced power distribution: Dedicated power planes ensure stable voltage delivery

- Increased circuit density: More space for complex routing in smaller form factors

Cost Implications

The cost doesn’t increase linearly with layer count. Instead, it follows a more complex pattern:

| Layer Count | Relative Cost | Manufacturing Time |

|---|---|---|

| 2 layers | 1x (baseline) | 1-2 days |

| 4 layers | 2-3x | 3-5 days |

| 8 layers | 4-6x | 1-2 weeks |

| 16+ layers | 10-20x | 3-4 weeks |

Frequently Asked Questions

Q: Can I have an odd number of PCB layers?

A: Yes, but it’s not recommended. Odd-layer PCBs are more prone to warping and mechanical stress because they lack symmetrical construction. Most manufacturers prefer even-layer designs for better reliability.

Q: What’s the most cost-effective layer count?

A: For most applications, 2-4 layers offer the best balance of performance and cost. However, the “most cost-effective” depends on your specific requirements and volume.

Q: How do I know if my PCB design needs more layers?

A: Signs you need more layers include:

- Difficulty routing all connections

- Signal integrity issues

- EMI/EMC compliance problems

- Insufficient space for proper ground planes

Q: What’s the difference between high-layer count and standard PCBs?

A: High-layer count PCBs (typically 10+ layers) require specialized manufacturing processes, materials, and equipment. They also need more sophisticated design software and experienced engineers.

Q: Can any manufacturer produce high-layer count PCBs?

A: No, high-layer count PCBs require advanced manufacturing capabilities. Only experienced manufacturers with specialized equipment can reliably produce PCBs with 10+ layers. For example, IPC standards provide guidelines for high-layer count PCB manufacturing.

Industry Trends & Future of PCB Layers

The PCB industry is evolving rapidly, driven by demands for smaller, faster, and more powerful electronic devices. Here are the key trends shaping the future of PCB layer counts:

Market Growth

According to recent market research, the high-layer count PCB market is experiencing significant growth:

- Market value: $16.8 billion in 2023

- Projected growth: Expected to reach $35.2 billion by 2033

- Growth rate: Approximately 7.6% annually

Driving Factors

Several factors are pushing the demand for higher layer count PCBs:

- 5G technology: Requires complex, high-frequency circuit designs

- AI and machine learning: Demand for high-performance computing boards

- Automotive electronics: Electric vehicles and autonomous driving systems

- IoT devices: Need for compact, multifunctional circuits

Emerging Applications

New applications are constantly pushing the boundaries of PCB layer counts:

- Data centers: Server motherboards with 20-40 layers

- Quantum computing: Requires extremely precise, high-layer count circuits

- Space exploration: Satellite and spacecraft electronics with 50+ layers

Industry experts predict that we’ll see continued growth in multilayer PCB adoption, especially in the semiconductor industry where miniaturization and performance are critical.

Conclusion

Understanding PCB layer counts is essential for anyone involved in electronics design and manufacturing. While PCBs can theoretically have up to 100+ layers (with the record being 129 layers), most practical applications use between 2-12 layers depending on complexity and budget requirements.

The key takeaways are:

- Start simple: Use the minimum number of layers that meet your requirements

- Consider your industry: Different sectors have different typical layer counts

- Balance cost and performance: More layers mean better performance but higher costs

- Think about the future: High-layer count PCBs are becoming more common in advanced applications

Whether you’re designing a simple LED controller or a complex server motherboard, choosing the right number of PCB layers is crucial for your project’s success.

Ready to Start Your PCB Project?

Get expert guidance on choosing the right PCB layer count for your specific application. Our experienced engineers can help you optimize your design for performance and cost.

Why Choose Mustar for Your PCB Needs?

- ✓ Capability to manufacture 1-64 layer PCBs

- ✓ Over 25 years of PCB manufacturing experience

- ✓ Advanced technologies including HDI and embedded components

- ✓ Certified to automotive (IATF16949) and medical (ISO13485) standards

- ✓ Fast turnaround times – samples in 4-8 hours

Contact us today to discuss your PCB layer requirements and get a customized solution that meets your exact specifications and budget.

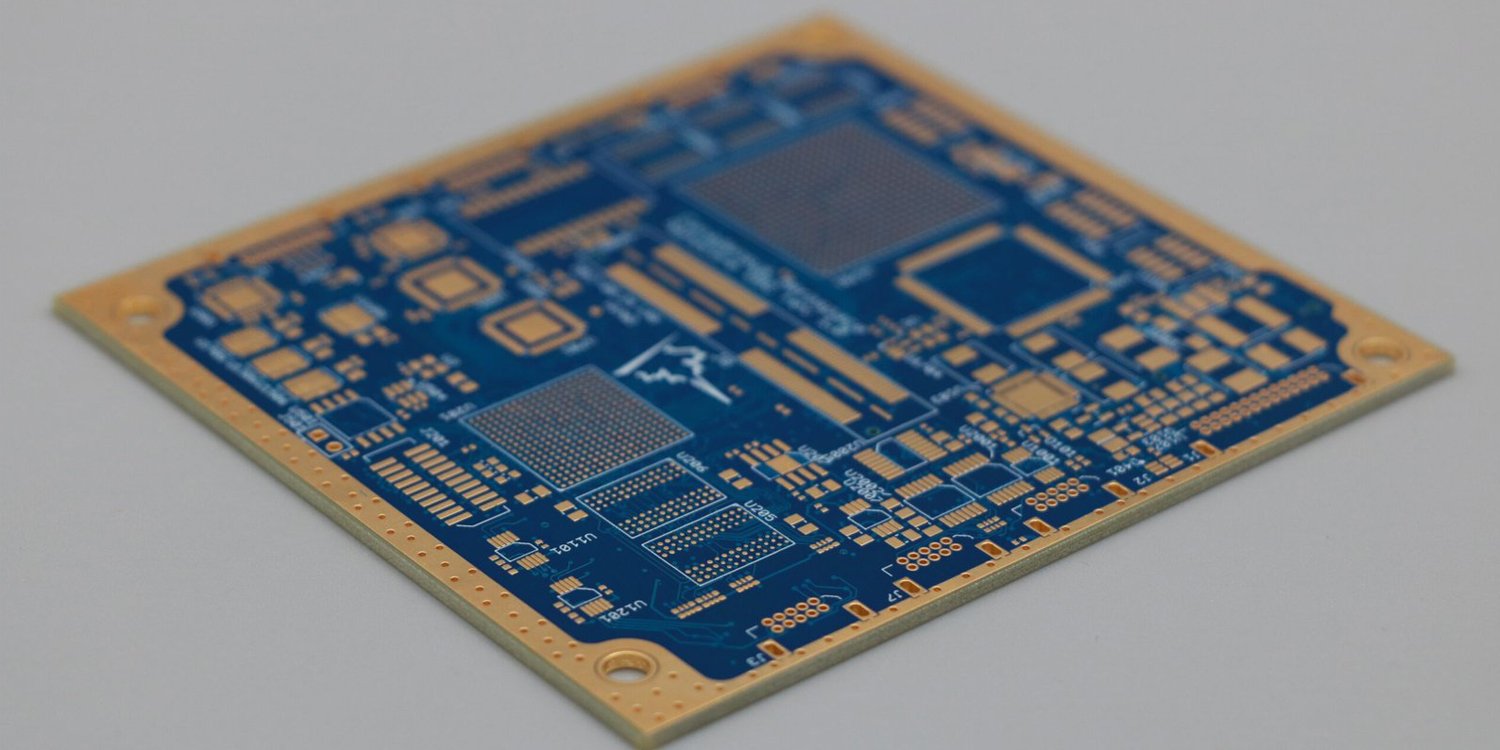

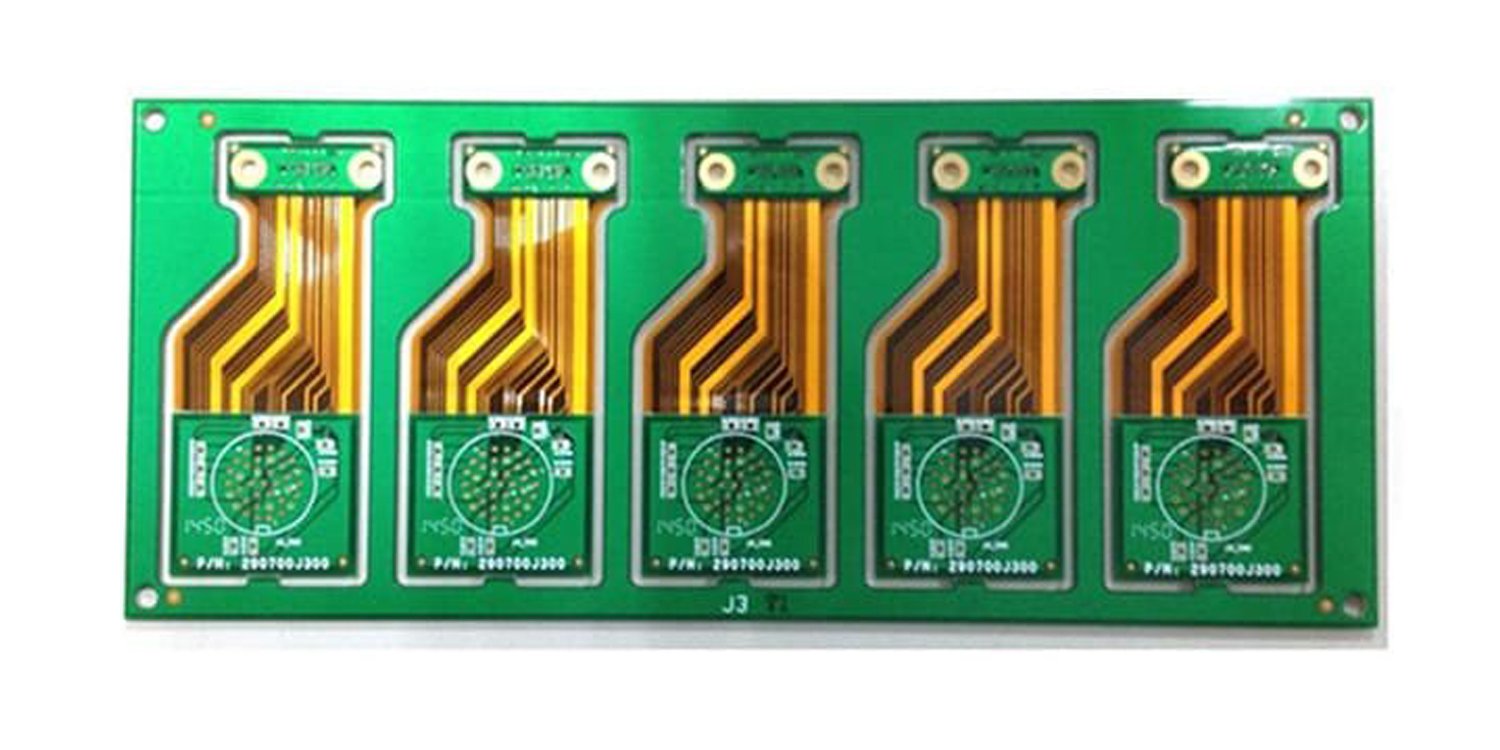

Mustar projects: