Contents

- What is Flexible PCBA(FPC) and why it’s essential in wearable devices?

- Key Applications of Flexible PCBA for Wearables

- FPC Design Considerations in Wearable Devices

- Industry Market Trends & Data

- Challenges and solutions in wearable flexible PCBA design

- Mustar’s strengths in flexible PCBA for wearables

- FAQs (Frequently Asked Questions)

- Conclusion:Embrace Flexible PCBA with Mustar for Next-Gen Wearables

What is Flexible PCBA(FPC) and why it’s essential in wearable devices?

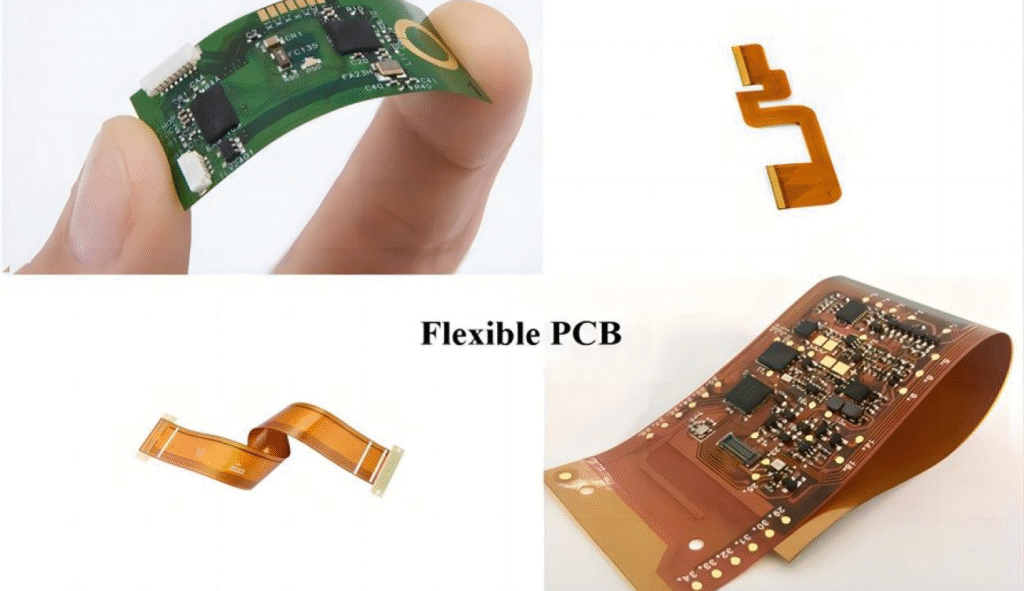

Flexible PCBA are printed circuit boards which can be bent, twisted, and conformed to irregular shapes, without compromising their electrical performance. Wearables are a great example of this flexibility, as they must fit comfortably to the contours of the human body and withstand constant movement.

The following are some of the benefits of using FPC for wearable devices:

-

Compact Design: Allows for ultra-slim and unobtrusive forms.

-

Durability Resistant against mechanical stress, such as twisting and bending.

-

Ergonomic integration: Seamlessly integrates curved surfaces such as wrists and skin.

-

Improved Performance: Reduced Signal Loss and improved Reliability in Tight Spaces.

Key Applications of Flexible PCBA for Wearables

-

Smartwatches & Fitness Trackers: Fit-for-purpose watches (FPCs) have slim profiles, curved designs and can be worn all day.

-

Medical Monitoring devices: Flexible PCBs can be used in patches or implants to measure health data continuously and non-invasively.

-

Wearable AR/VR and Smart Eyewear : Flexible and lightweight boards improve device comfort and performance without sacrificing weight.

FPC Design Considerations in Wearable Devices

-

Bend radius: In order to prevent circuit damage, a dynamic bend radius of at least 10 times that of the FPC is required. A board that is 0.1mm thick requires a bend radius of at least 1mm.

-

Layer stack: Wearable components commonly use 1 to 4 layers in order to maximize flexibility and support multi-functional components.

-

Placement of components: Important components should be placed away from zones with high flex. Stiffeners are often used to reinforce connector areas.

-

Material Selection: Polyimide substrates, biocompatible materials and skin-contact devices are durable.

Industry Market Trends & Data

| Attribute | Data / Detail | Source/Notes |

|---|---|---|

| Global Flexible PCB market size (2023). | $21.42 billion | Industry Reports |

| Market size projections (2032). | $61,75 billion (CAGR of 12.5%). | Market Forecasts |

| Consumer Electronics Segment Revenue (2022) | 8 billion dollars | Substantial wearable device share |

| Reduce Device Thickness Using FPC | From 10mm down to less than 5mm | Wearables are a popular trend. |

| Dynamic bend radius for durability | Thickness >=10x of FPC | Engineering best practices |

The market for flexible PCBs is growing rapidly, driven by the demand for multifunctional, compact and lightweight wearable devices. The adoption of 5G integration, medical monitoring expansion and other advancements is also boosted.

Challenges and solutions in wearable flexible PCBA design

Challenges:

-

FPCs are subjected to repeated bending, twisting and torsion. This can lead to component or trace failure.

-

The selection of materials must be balanced between flexibility, electrical performance and mechanical resistance.

-

Devices that directly contact users must be biocompatible and safe for the skin.

Solutions From Mustar:

-

Use of high-grade Polyimide materials, and advanced stacking that increases flex durability.

-

Stiffeners on connectors reinforce the placement of components away from flex zones.

-

To ensure reliability, we conduct comprehensive testing and quality controls, including AOI, functional and X-ray testing.

Mustar’s strengths in flexible PCBA for wearables

Mustar, a Shenzhen-based PCBA manufacturer of 25+ years experience, offers:

-

Comprehensive one-stop solutions: From fabrication of PCBs (1-64 layers, including flexible and rigid flex), to component sourcing, and final assembly.

-

Advanced Manufacturing: 16 lines of SMT (including medical grade lines), precision assembly of 01005, BGA and QFN components.

-

Quality Assurance Certified ISO 9001 (medical), ISO 13485 Automotive, IATF 16949 Automobile plus IPC A-610E Class II quality standards.

-

Fast Turnaround & Cost Efficiency: 10% savings compared to competitors. Prototyping in 3-7 days without a minimum order quantity.

-

Global Experience Serving over 98 countries including long-term partners like Germany Telecom.

Mustar’s expertise allows wearable device manufacturers to reduce the size and weight of their products while maintaining durability and high performance.

FAQs (Frequently Asked Questions)

1. Why are flexible PCBs preferred to rigid PCBs in wearables

Wearables are more comfortable and durable because flexible PCBAs can bend and conform to the body shape. Miniaturization is possible without compromising reliability.

2. What is the typical thickness and bend radius specification for FPC used in wearable devices

Wearables require FPC boards with thicknesses between 0.01mm and 0.3mm, as well as minimum dynamic bend radiuses of at least 10x the board thickness.

3. Mustar’s flexible PCBAs are designed to be wornable

Mustar performs 100% inline and final functional tests, AOI inspections, X-rays and E-tests to detect defects. We follow strict IPC, ISO and medical standards.

4. Mustar stands out from other PCBA manufacturers

We offer unmatched flexibility and quality with our combination of cost-effective manufacturing, rapid prototyping and international certifications.

Conclusion:Embrace Flexible PCBA with Mustar for Next-Gen Wearables

The evolution of wearable technologies is based on flexible PCBAs (FPCs), which allow for sleek designs that do not compromise durability or performance. The wearable market is expected to grow exponentially. Partnering with an experienced manufacturer such as Mustar will ensure that your product meets design innovations, manufacturing excellence and cost efficiency.

Visit MUSTAR or contact us for expert consultation and flexible PCBA solutions tailored to your wearable technology needs.

Mustar projects: