🚀 UPS Market Explosive Growth

| Year | UPS Market Size (Billion USD) | CAGR (%) |

|---|---|---|

| 2024 | $10.06 | 8.2% |

| 2025 | $10.88 | 8.2% |

| 2029 | $14.77 | 7.9% |

Source: The Business Research Company, 2025

The demand for customized PCBA solutions for UPS systems has skyrocketed as businesses seek reliable power backup solutions. Meanwhile, the global UPS market is projected to grow from $10.06 billion in 2024 to an impressive $14.77 billion by 2029. Furthermore, this explosive growth creates massive opportunities for companies needing tailored UPS circuit board assembly solutions.

In this comprehensive guide, we’ll explore everything you need to know about customized PCBA for UPS systems. Additionally, you’ll discover why customization matters, key design considerations, and how to choose the right manufacturing partner for your project.

Contents

- What Are Customized PCBA Solutions for UPS Systems?

- Key Benefits of Customized UPS PCBA Solutions

- Critical Design Considerations for UPS PCBA

- The Customization Process: From Concept to Production

- Market Growth and Industry Trends

- Quality Control and Testing Standards

- Why Choose Mustar for Your Customized UPS PCBA

- Frequently Asked Questions About UPS PCBA

- Conclusion

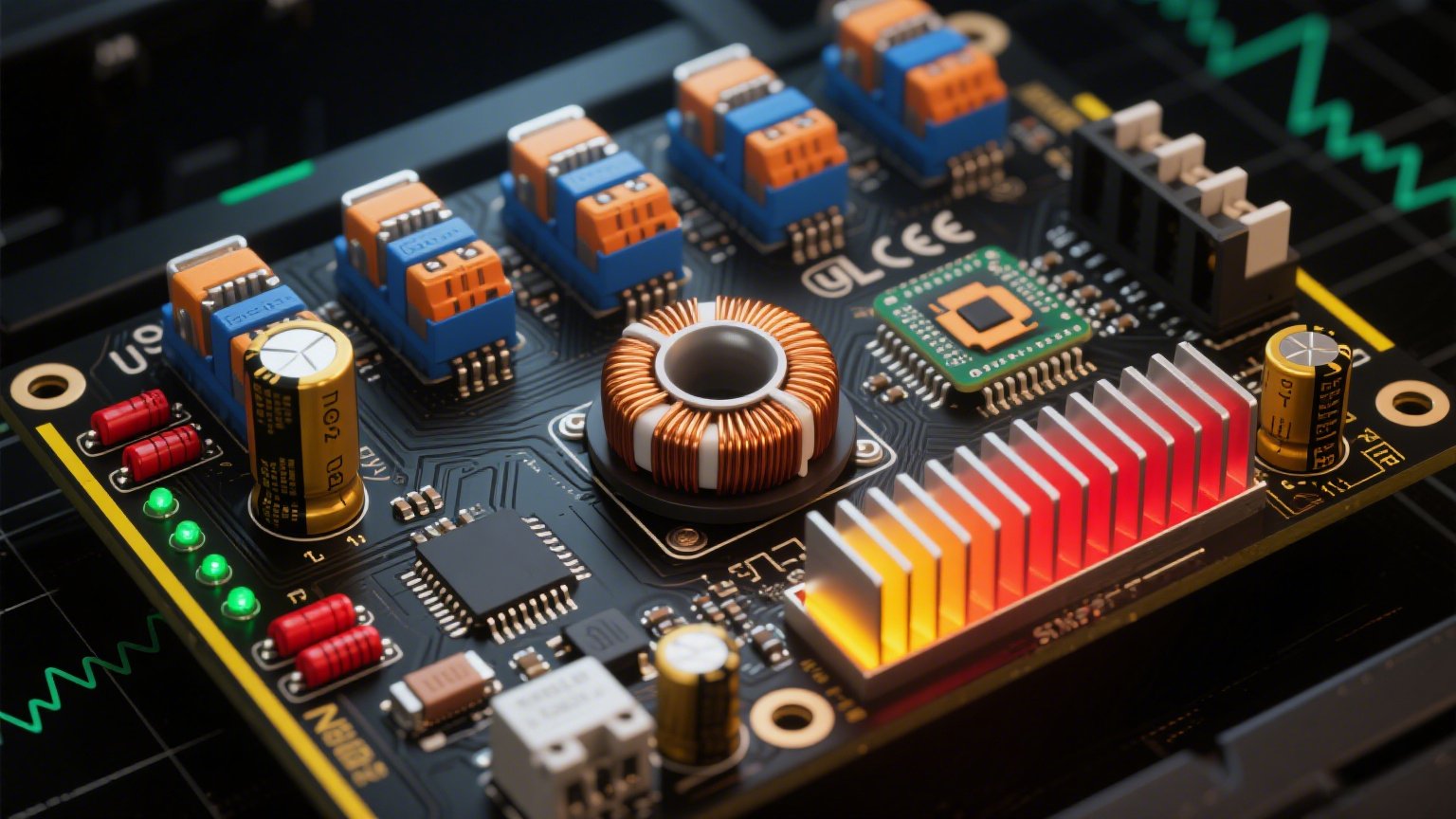

What Are Customized PCBA Solutions for UPS Systems?

💡 Quick Definition

Customized PCBA for UPS refers to the design and assembly of printed circuit boards tailored specifically to the requirements of uninterruptible power supply systems. This includes adapting the design for power handling, battery management, thermal considerations, and protection features to ensure reliable and efficient UPS operation.

Unlike standard off-the-shelf solutions, customized UPS PCBA designs meet your exact specifications. Moreover, these tailored solutions address specific voltage requirements, current loads, and environmental conditions. As a result, you get better performance, reliability, and cost-effectiveness.

The key components of customized UPS PCBA solutions include:

- Power conversion circuits – Convert DC battery power to AC output efficiently

- Battery management systems – Monitor and control charging cycles safely

- Control and monitoring circuits – Provide real-time system status feedback

- Protection circuits – Safeguard against overcurrent, overvoltage, and thermal issues

Key Benefits of Customized UPS PCBA Solutions

Choosing customized PCBA solutions for UPS systems offers significant advantages over generic alternatives. First, let’s explore how customization transforms your UPS performance and business outcomes.

Enhanced Performance and Reliability

Custom UPS PCBA designs optimize every component for your specific application. Consequently, you achieve better power conversion efficiency, reduced heat generation, and longer component lifespan. Moreover, tailored designs eliminate unnecessary features while strengthening critical functions.

“Customized PCBA solutions can improve UPS efficiency by up to 15% compared to standard designs, resulting in significant energy savings over time.” – IEEE Power Electronics Society

Cost Optimization Through Tailored Design

Although initial development costs may be higher, customized UPS PCBA solutions deliver long-term savings. Furthermore, you only pay for components you actually need. Additionally, optimized designs reduce manufacturing waste and improve yield rates.

Faster Time-to-Market Advantages

Working with experienced PCBA manufacturers accelerates your product development cycle. Similarly, proven design methodologies and rapid prototyping capabilities help you launch products faster. As a result, you can capture market opportunities before competitors.

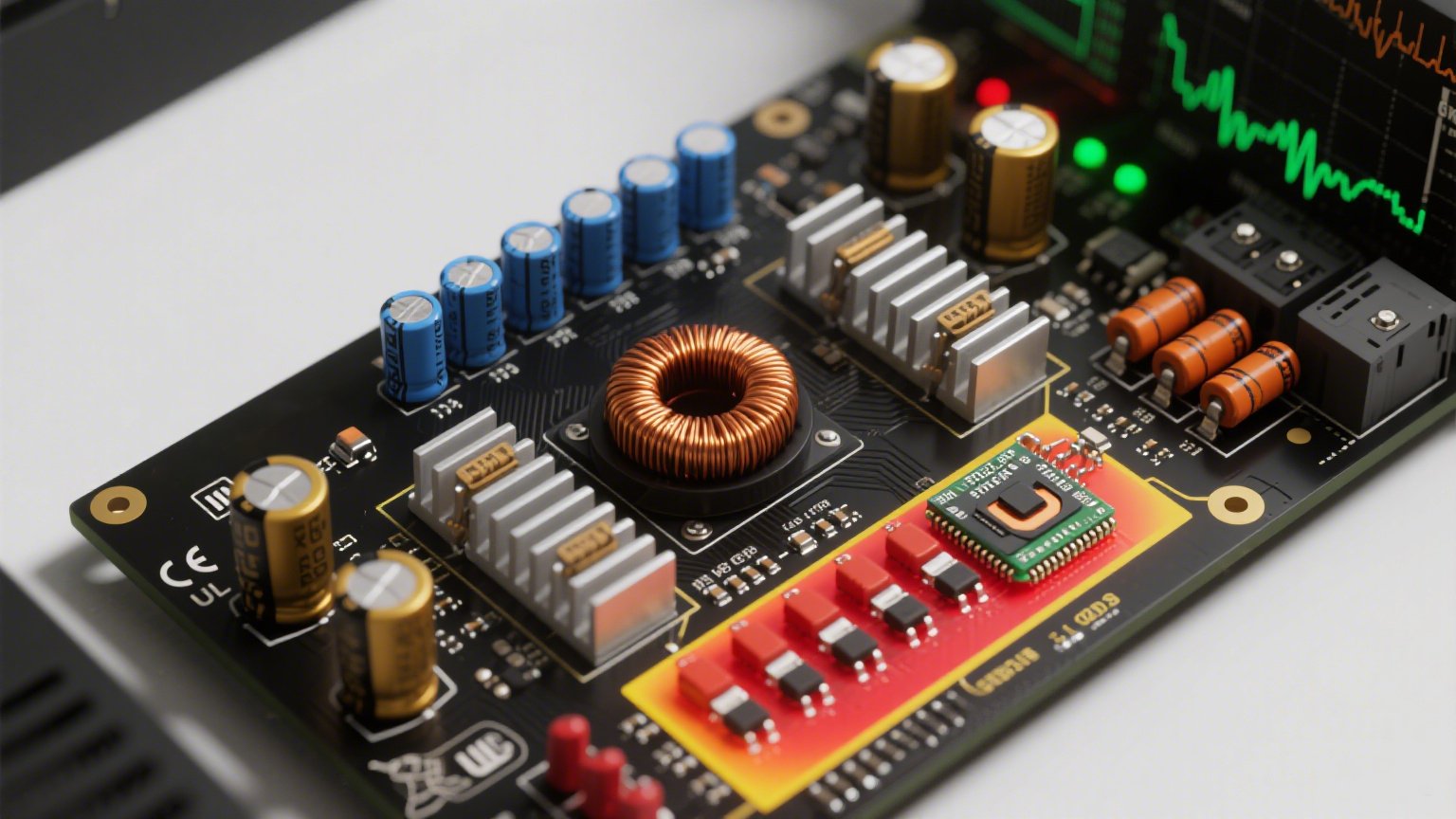

Better Thermal Management and Efficiency

Custom designs address thermal challenges specific to your UPS application. Therefore, you get better heat dissipation, improved component placement, and enhanced reliability under demanding conditions.

Critical Design Considerations for UPS PCBA

Designing effective customized PCBA solutions for UPS requires careful attention to several critical factors. Moreover, each consideration impacts overall system performance and reliability.

| Design Consideration | Description | Importance |

|---|---|---|

| Thermal Management | Heat sinks, thermal vias, component placement | Prevents overheating, extends PCB lifespan |

| Power Conversion Efficiency | High-efficiency switching regulators and inverters | Minimizes power loss and heat generation |

| Component Selection | Voltage/current ratings, temperature tolerance | Ensures stable operation and reduces failures |

| High Current Load Handling | PCB trace and via design for high current | Prevents voltage drop and trace burnout |

| EMI/EMC Compliance | Shielding, filtering, grounding | Reduces interference and ensures system stability |

Thermal Management Solutions

Effective thermal management is crucial for UPS PCBA reliability. First, proper component placement distributes heat evenly across the board. Additionally, thermal vias and copper pours help conduct heat away from critical components. Furthermore, selecting components with appropriate temperature ratings ensures stable operation.

High Current Load Handling

UPS systems must handle significant current loads during battery discharge and charging cycles. Therefore, PCB trace width calculations become critical for safe operation. Moreover, proper via sizing and copper thickness prevent overheating and voltage drops.

EMI/EMC Compliance Requirements

Switching power supplies in UPS systems generate electromagnetic interference that can affect nearby equipment. Consequently, proper shielding, filtering, and grounding techniques are essential. Additionally, compliance with FCC regulations and international EMC standards ensures market acceptance.

The Customization Process: From Concept to Production

Understanding the customized PCBA solutions for UPS development process helps you plan your project effectively. Moreover, working with experienced manufacturers streamlines each phase from initial concept to full production.

Step 1: Requirements Analysis Phase

The customization process begins with thorough requirements analysis. First, engineers evaluate your specific UPS application needs. Additionally, they consider factors such as:

- Power specifications – Input/output voltage and current requirements

- Environmental conditions – Operating temperature, humidity, and vibration

- Size constraints – Physical dimensions and weight limitations

- Regulatory requirements – Safety standards and certifications needed

Step 2: Design and Prototyping Stages

Once requirements are clear, the design phase begins. Furthermore, experienced engineers create detailed schematics and PCB layouts optimized for your application. Subsequently, rapid prototyping allows for early testing and validation.

Step 3: Testing and Quality Assurance

Comprehensive testing ensures your customized UPS PCBA meets all specifications. Moreover, testing includes functional verification, thermal analysis, and reliability assessments. Additionally, compliance testing validates regulatory requirements.

Market Growth and Industry Trends

The market for customized PCBA solutions for UPS continues expanding rapidly. Moreover, several industry trends drive this growth and create new opportunities.

| Year | PCB Assembly Market Size (Billion USD) | CAGR (%) |

|---|---|---|

| 2024 | $36.3 | 5.9% |

| 2033 | $54.8 | 5.9% |

Source: Verified Market Reports, 2025

Emerging Technologies Affecting UPS Design

Several technological advances are reshaping UPS PCBA design requirements. First, lithium-ion battery adoption demands sophisticated battery management systems. Additionally, IoT connectivity requires integrated communication modules. Furthermore, smart grid integration drives demand for advanced monitoring capabilities.

Future Opportunities in the Sector

The growing emphasis on renewable energy creates new opportunities for customized UPS PCBA solutions. Moreover, data center expansion and cloud computing growth fuel demand for reliable power backup systems. Additionally, electric vehicle charging infrastructure requires robust UPS solutions.

Quality Control and Testing Standards

Rigorous quality control ensures your customized PCBA solutions for UPS meet demanding reliability requirements. Furthermore, comprehensive testing protocols validate performance under various operating conditions.

Testing Methods and Standards

Professional PCBA manufacturers employ multiple testing methodologies to ensure quality. First, in-circuit testing (ICT) verifies component placement and soldering quality. Additionally, functional circuit testing (FCT) confirms proper operation under real-world conditions.

- Flying probe tests – Verify connectivity and component values

- Thermal shock tests – Validate performance under temperature cycling

- Solderability tests – Ensure reliable solder joint formation

- Impedance tests – Verify signal integrity for high-speed circuits

Reliability Requirements

UPS systems often operate in mission-critical applications where failure is not acceptable. Therefore, reliability testing becomes paramount for customized UPS PCBA designs. Moreover, accelerated life testing predicts long-term performance and identifies potential failure modes.

Compliance Certifications Needed

Depending on your application and target markets, various certifications may be required. Furthermore, working with manufacturers who understand regulatory requirements simplifies the compliance process. Additionally, common certifications include UL safety standards, CE marking for European markets, and FCC approval for electronic devices.

Why Choose Mustar for Your Customized UPS PCBA

Mustar brings over 25 years of experience in delivering high-quality customized PCBA solutions for UPS systems. Moreover, our comprehensive capabilities and certifications make us the ideal partner for your next project.

Company Expertise and Certifications

Our extensive certifications demonstrate our commitment to quality and compliance:

- ISO9001 – Quality management system certification

- ISO13485 – Medical device quality standards

- IATF16949 – Automotive quality certification

- ISO14001 – Environmental management certification

- CE, RoHS, UL – International safety and environmental compliance

Specialized Capabilities for UPS Applications

Mustar’s advanced manufacturing capabilities perfectly suit UPS PCBA requirements. First, our facility spans 12,000 square meters with over 600 skilled employees. Additionally, we operate 20 SMT lines including 6 dedicated automotive and medical lines for high-reliability applications.

🏭 Manufacturing Capabilities

- PCB Manufacturing: 1 to 64-layer PCBs with advanced technologies

- Component Sourcing: 200+ global suppliers with 100% BOM compliance

- Assembly Services: SMT, DIP, and mixed technology assembly

- Testing Equipment: ICT, FCT, 3D SPI, X-Ray, and AOI capabilities

Success Stories and Client Benefits

Mustar has successfully supported over 100 automotive electronics enterprises in rapidly growing their market presence. Furthermore, our clients consistently praise our quality, engineering support, and reliable delivery schedules. Additionally, our technical expertise helps clients optimize their designs for better performance and cost-effectiveness.

Frequently Asked Questions About UPS PCBA

❓ Common Questions

What is customized PCBA for UPS?

Customized PCBA for UPS refers to the design and assembly of printed circuit boards tailored specifically to uninterruptible power supply system requirements. This includes adapting designs for power handling, battery management, thermal considerations, and protection features to ensure reliable operation.

Why is customization important in UPS PCBA?

Customization allows PCBA designs to meet precise electrical, thermal, and mechanical requirements of UPS systems. Moreover, this improves reliability, efficiency, and safety while enabling cost optimization through tailored component selection.

What are the key design challenges in UPS PCB assembly?

Key challenges include managing high current loads, ensuring efficient heat dissipation, selecting components for harsh operating conditions, and minimizing electromagnetic interference. Furthermore, proper layout and comprehensive testing are critical for overcoming these challenges.

How does customized PCBA improve UPS performance?

Customized PCBA solutions improve UPS performance by optimizing power conversion efficiency, enhancing thermal management, and integrating advanced battery management systems. Consequently, this leads to longer lifespan, better energy efficiency, and reliable power backup.

What testing standards are used for UPS PCBA?

Common testing standards include flying probe tests, solderability tests, thermal shock tests, impedance tests, and metallographic analysis. Additionally, these tests ensure PCBA meets quality, reliability, and safety requirements essential for UPS applications.

What is the market outlook for UPS and PCBA industries?

The UPS market is expected to grow from $10.06 billion in 2024 to $14.77 billion by 2029. Meanwhile, the PCB assembly market is projected to grow from $36.3 billion in 2024 to $54.8 billion by 2033, driven by electronics, AI, 5G, and IoT demand.

Conclusion: Transform Your UPS Performance with Customized PCBA Solutions

The future belongs to companies that choose customized PCBA solutions for UPS systems over generic alternatives. Moreover, with the UPS market growing at 8.2% annually, now is the perfect time to invest in tailored solutions that give you competitive advantages.

Throughout this guide, we’ve explored how customization delivers superior performance, reliability, and cost-effectiveness. Furthermore, working with experienced manufacturers like Mustar ensures your project succeeds from concept to production.

🚀 Ready to Get Started?

Don’t let standard solutions limit your UPS performance. Partner with Mustar for customized PCBA solutions that exceed your expectations.

✅ 25+ Years Experience

✅ ISO Certified Quality

✅ 200+ Global Suppliers

✅ Fast Prototyping

Contact our experts today and discover how customized PCBA solutions can transform your UPS performance!

📞 Contact Information

Website: pcbamustar.com

Email: sales@mustarpcba.com

Phone: +86 136 8883 2535

Address: Floor 6th, Building C, Qianwanying Technology Industrial Park, Bao’an, Shenzhen, Guangdong, China

Mustar projects: