| Application Area | Market Size/Growth | Key Requirements | Common Products |

|---|---|---|---|

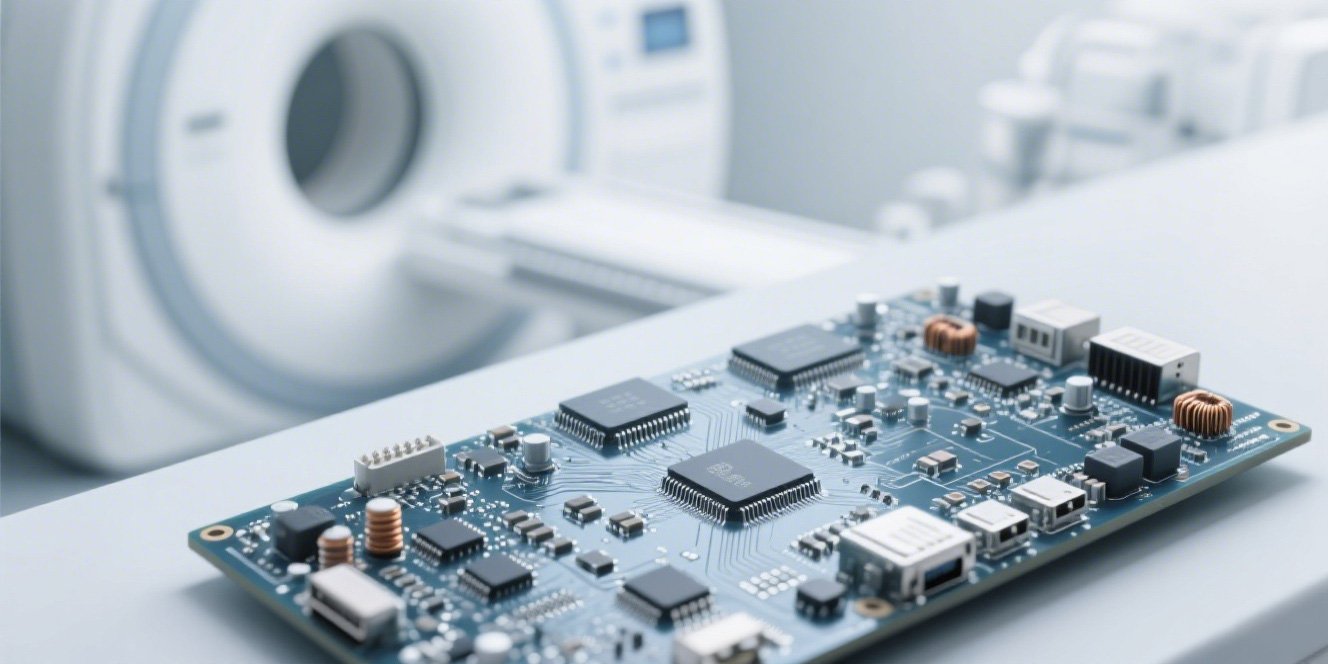

| Medical Devices | Growing HDI & Flexible PCB demand | High reliability, small size | Pacemakers, monitors, imaging systems |

| Consumer Electronics | 77% smartphone ownership in US | High density, low cost | Smartphones, laptops, tablets |

| Automotive | Safety systems expansion | Temperature tolerance, vibration resistance | Engine control, safety systems |

| Industrial Equipment | Automation growth | Thermal resistance, rugged materials | Power control, automation systems |

| Telecommunications | 5G and IoT expansion | High-frequency capabilities | Routers, towers, IoT devices |

| Aerospace & Defense | Rigid-flex PCB adoption | High reliability, lightweight | Flight systems, military equipment |

| Global Market | $9.1B to $21.46B (2023-2032) | 10% CAGR growth rate | All electronic products |

Contents

- What is PCBA and Why Does Every Industry Need It?

- Top 7 Industries Using PCBA Technology

- Medical Devices: Life-Saving PCBA Applications

- Consumer Electronics: PCBA in Your Daily Life

- Automotive Industry: Driving Safety with PCBA

- Industrial Equipment: Heavy-Duty PCBA Solutions

- Telecommunications: Connecting the World Through PCBA

- Emerging PCBA Applications for 2025

- Market Growth: PCBA Industry Projections

- Choosing the Right PCBA Manufacturer

- Frequently Asked Questions About PCBA Applications

- Conclusion

What is PCBA and Why Does Every Industry Need It?

PCBA stands for Printed Circuit Board Assembly. Think of it as the brain of every electronic device you use daily. Furthermore, PCBA combines a printed circuit board with electronic components like resistors, capacitors, and microchips.

Every modern device needs PCBA because it connects all the electronic parts together. Additionally, without PCBA, your smartphone couldn’t make calls, and your car’s safety systems wouldn’t work. Moreover, PCBA makes devices smaller, faster, and more reliable than ever before.

Fun Fact: A single smartphone contains multiple PCBA boards, each designed for different functions like processing, communication, and power management.

Top 7 Industries Using PCBA Technology

The following industries rely heavily on PCBA technology for their operations:

- Medical Devices – Life-saving equipment and monitoring systems

- Consumer Electronics – Smartphones, computers, and entertainment devices

- Automotive – Engine control, safety systems, and infotainment

- Industrial Equipment – Automation systems and power control

- Telecommunications – Network infrastructure and IoT devices

- Aerospace & Defense – Flight systems and military equipment

- Emerging Technologies – AI robotics and green energy systems

These industries represent the backbone of modern technology. Similarly, each sector has unique requirements that shape how PCBA is designed and manufactured.

Medical Devices: Life-Saving PCBA Applications

Medical devices demand the highest quality PCBA because people’s lives depend on them. Consequently, medical PCBA must meet strict standards for reliability and safety.

Common medical PCBA applications include:

- Pacemakers – Tiny boards that regulate heartbeats

- Imaging systems – MRI and CT scanner control boards

- Patient monitors – Heart rate and vital sign displays

- Respiratory equipment – Ventilator control systems

- Surgical instruments – Precision cutting and monitoring tools

Medical PCBA requires ISO13485 certification to ensure patient safety. Additionally, these boards often use flexible materials to fit inside small medical devices. FDA medical device regulations guide the strict manufacturing standards.

Consumer Electronics: PCBA in Your Daily Life

Consumer electronics represent the largest PCBA market globally. With 77% smartphone ownership in the US, demand for miniaturized PCBA continues growing rapidly.

Popular consumer electronics using PCBA include:

- Smartphones – Multiple boards for processing, camera, and battery management

- Laptops and tablets – Motherboards with integrated graphics and storage

- Gaming devices – High-performance boards for smooth gameplay

- Smart home devices – IoT-enabled appliances and security systems

- Wearable technology – Fitness trackers and smartwatches

Consumer PCBA focuses on cost-effectiveness and miniaturization. Moreover, manufacturers use advanced techniques like HDI (High Density Interconnect) to pack more features into smaller spaces. Global smartphone statistics show the massive scale of this market.

Automotive Industry: Driving Safety with PCBA

Automotive PCBA must survive extreme conditions while ensuring passenger safety. Therefore, automotive boards face unique challenges like temperature swings, vibrations, and electromagnetic interference.

Key automotive PCBA applications include:

- Engine control units – Managing fuel injection and ignition timing

- Safety systems – Airbag controllers and collision detection

- Driver assistance – Parking sensors and lane departure warnings

- Infotainment systems – Navigation, audio, and connectivity features

- Electric vehicle components – Battery management and charging systems

Automotive PCBA requires IATF16949 certification for quality assurance. Additionally, these boards must withstand temperatures from -40°C to 125°C. SAE automotive standards define the strict requirements for automotive electronics.

Industrial Equipment: Heavy-Duty PCBA Solutions

Industrial PCBA operates in harsh environments with dust, moisture, and extreme temperatures. Consequently, these boards require special materials and protective coatings for long-term reliability.

Common industrial PCBA applications include:

- Factory automation – Robotic assembly line controllers

- Power management – High-voltage switching and distribution

- Motor drives – Variable frequency drives for industrial motors

- Process control – Temperature and pressure monitoring systems

- Safety systems – Emergency shutdown and alarm systems

Industrial PCBA emphasizes durability and thermal resistance. Furthermore, many industrial boards use through-hole components for better mechanical strength. NEMA industrial standards guide the design requirements for industrial electronics.

Telecommunications: Connecting the World Through PCBA

Telecommunications PCBA enables global connectivity through internet, cellular, and satellite networks. Moreover, the 5G rollout drives demand for high-frequency PCBA with advanced signal processing capabilities.

Telecommunications PCBA applications include:

- Cell towers – Base station equipment and signal amplifiers

- Network equipment – Routers, switches, and fiber optic systems

- IoT devices – Smart sensors and connected appliances

- Satellite systems – Communication satellites and ground stations

- Data centers – Server motherboards and networking hardware

Telecom PCBA requires high-frequency materials like Rogers laminates for optimal signal performance. Additionally, outdoor equipment needs weatherproof coatings and UV protection. IEEE telecommunications standards ensure compatibility and performance across networks.

Emerging PCBA Applications for 2025

New technologies create exciting opportunities for PCBA applications. Furthermore, these emerging markets show strong growth potential for manufacturers and suppliers.

Flexible PCBs for Wearables

Flexible PCBA enables bendable electronics in smartwatches, fitness trackers, and medical patches. Additionally, flexible circuits conform to curved surfaces and moving parts.

AI and Robotics Applications

Artificial intelligence requires specialized PCBA for machine learning processors and neural networks. Similarly, robotics demands precise motor control and sensor integration boards.

Green Energy Systems

Solar inverters, wind turbine controllers, and battery management systems drive demand for power electronics PCBA. Moreover, electric vehicle charging stations need high-power PCBA solutions.

Trend Alert: Flexible and rigid-flex PCBA markets are growing 15% annually, driven by wearable technology and IoT devices.

Market Growth: PCBA Industry Projections

The global PCBA market shows impressive growth across all sectors. Moreover, technological advancement and increased electronics adoption drive this expansion.

Growth Rate: 10% CAGR from 2024-2032

Regional Market Insights

- Asia Pacific – Dominates manufacturing with 60% market share

- North America – Leads innovation and high-tech applications

- Europe – Strong automotive and industrial markets

- Rest of World – Emerging markets showing rapid growth

Key growth drivers include automotive electrification, 5G infrastructure, and IoT device proliferation. Additionally, market research reports confirm these positive trends across all application areas.

Choosing the Right PCBA Manufacturer

Selecting the right PCBA manufacturer impacts product quality, delivery time, and total cost. Therefore, consider these key factors when choosing a partner:

Experience and Track Record

Look for manufacturers with proven experience in your industry. For example, Mustar’s 25+ years of experience demonstrates deep knowledge across multiple sectors.

Certifications and Standards

Verify that manufacturers hold relevant certifications:

- ISO9001 – Quality management systems

- ISO13485 – Medical device manufacturing

- IATF16949 – Automotive quality standards

- IPC standards – Electronic assembly best practices

Manufacturing Capabilities

Ensure the manufacturer can handle your specific requirements:

- Layer count (1-64 layers)

- Component types (SMT, through-hole, BGA)

- Volume requirements (prototype to high-volume)

- Testing capabilities (ICT, FCT, AOI)

Pro Tip: Choose manufacturers with dedicated production lines for your industry to ensure quality and compliance.

Frequently Asked Questions About PCBA Applications

The main industries using PCBA include healthcare (medical devices), consumer electronics (smartphones, computers), automotive (engine control units, safety systems), industrial equipment (automation, power control), aerospace and defense (flight systems, military equipment), and telecommunications (networking devices, IoT).

PCBA is crucial in medical devices because it enables compact, reliable, and high-density circuit designs necessary for critical applications such as pacemakers, imaging systems, and monitors. Medical PCBs must meet strict sanitation and reliability standards to ensure patient safety.

PCBA is evolving with trends like flexible and rigid-flex PCBs supporting IoT and wearable devices, high-frequency PCBs for telecommunications, and advanced materials enhancing durability and miniaturization. These innovations enable smarter, lighter, and more efficient electronics across industries.

Automotive PCBA must withstand extreme temperatures, vibrations, and harsh environments while ensuring high reliability for safety-critical functions. This requires specialized materials like high-temperature laminates and robust assembly techniques such as through-hole mounting and rigid-flex designs.

The global PCB assembly market was valued at USD 9.1 billion in 2023 and is expected to grow to USD 21.46 billion by 2032, with a CAGR of 10% from 2024 to 2032. Growth is driven by rising demand in automotive, aerospace, defense, and consumer electronics sectors.

Conclusion: Partner with Experienced PCBA Manufacturers

Ready to Start Your Next PCBA Project?

PCBA applications span every industry from life-saving medical devices to everyday consumer electronics. With the market growing to $21.46 billion by 2032, choosing the right manufacturing partner is crucial for success.

Mustar brings 25+ years of experience across all major PCBA application areas. Our certifications include ISO13485 for medical devices, IATF16949 for automotive, and advanced capabilities for aerospace, industrial, and consumer electronics.

Whether you need prototype development or high-volume production, our expert team delivers quality PCBA solutions on time and within budget.

Contact Mustar: Email us at sales@mustarpcba.com or call +86 136 8883 2535

Experience the difference of working with a trusted PCBA manufacturing partner.

Mustar projects: