🚀 Quick Reference: Chinese PCB Assembly at a Glance

| Factor | Details |

|---|---|

| Global Market Share | 54% (Largest worldwide) |

| Industry Value | $44+ Billion USD |

| Small Batch Cost | $200-$700 (10 boards) |

| Minimum Order | As low as 1-5 boards |

| Lead Time | 4-8 hours (samples) to weeks (production) |

Key Takeaway: China offers the world’s most comprehensive PCB assembly ecosystem, combining cost efficiency with advanced manufacturing capabilities.

Contents

- What is Chinese PCB Assembly?

- Chinese PCB Assembly Cost Breakdown

- Future of Chinese PCB Assembly

- Your Next Steps in Chinese PCB Assembly

- Why China Dominates Global PCB Assembly

- Types of Chinese PCB Assembly Services

- Quality Control Standards in Chinese PCB Assembly

- Complete Guide: How to Order PCB Assembly from China

- Common Challenges and How to Avoid Them

When it comes to Chinese PCB assembly, you’re looking at the world’s largest and most advanced manufacturing hub. Furthermore, China dominates the global electronics manufacturing landscape with impressive statistics that speak volumes about its capabilities.

In this comprehensive guide, we’ll explore everything you need to know about Chinese PCB assembly services. Additionally, we’ll provide practical insights to help you make informed decisions for your next project.

What is Chinese PCB Assembly?

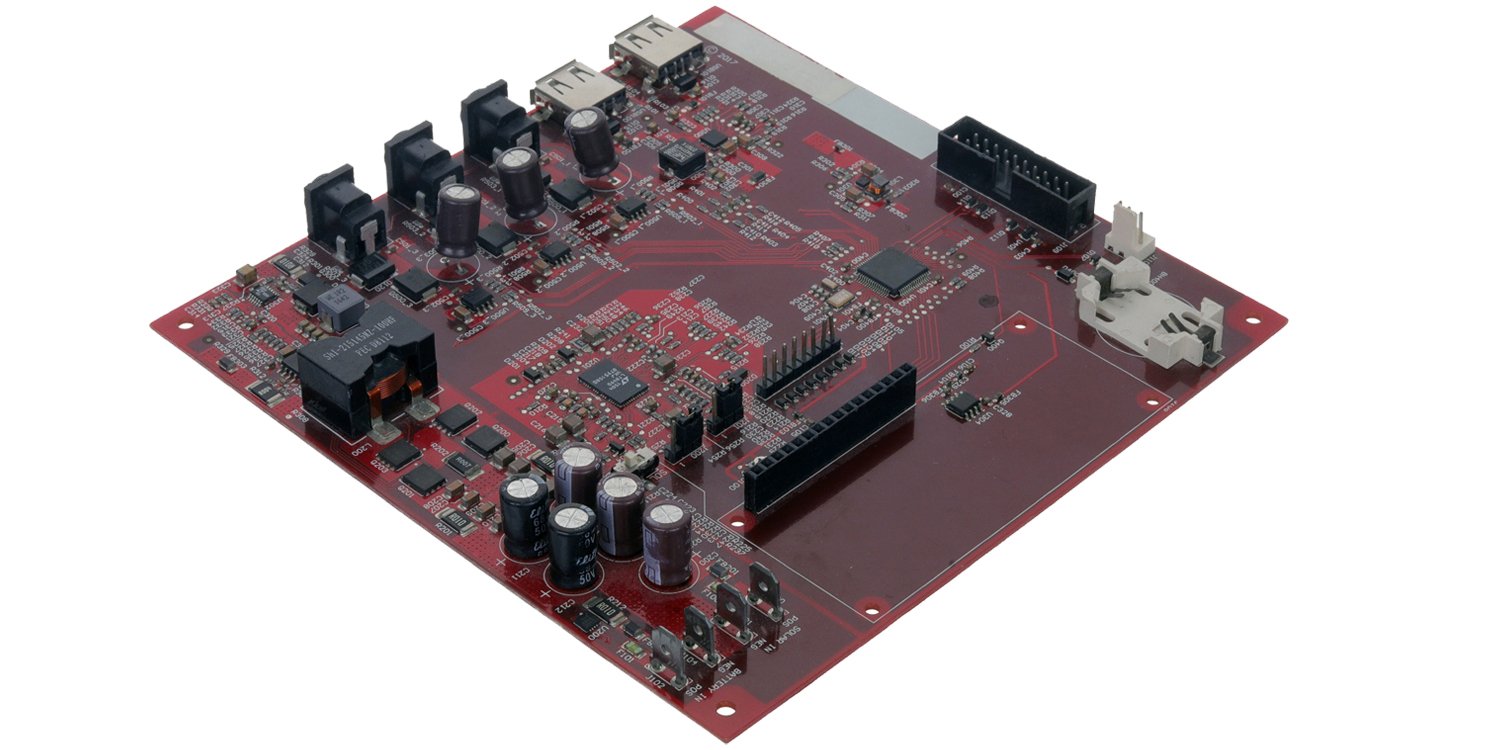

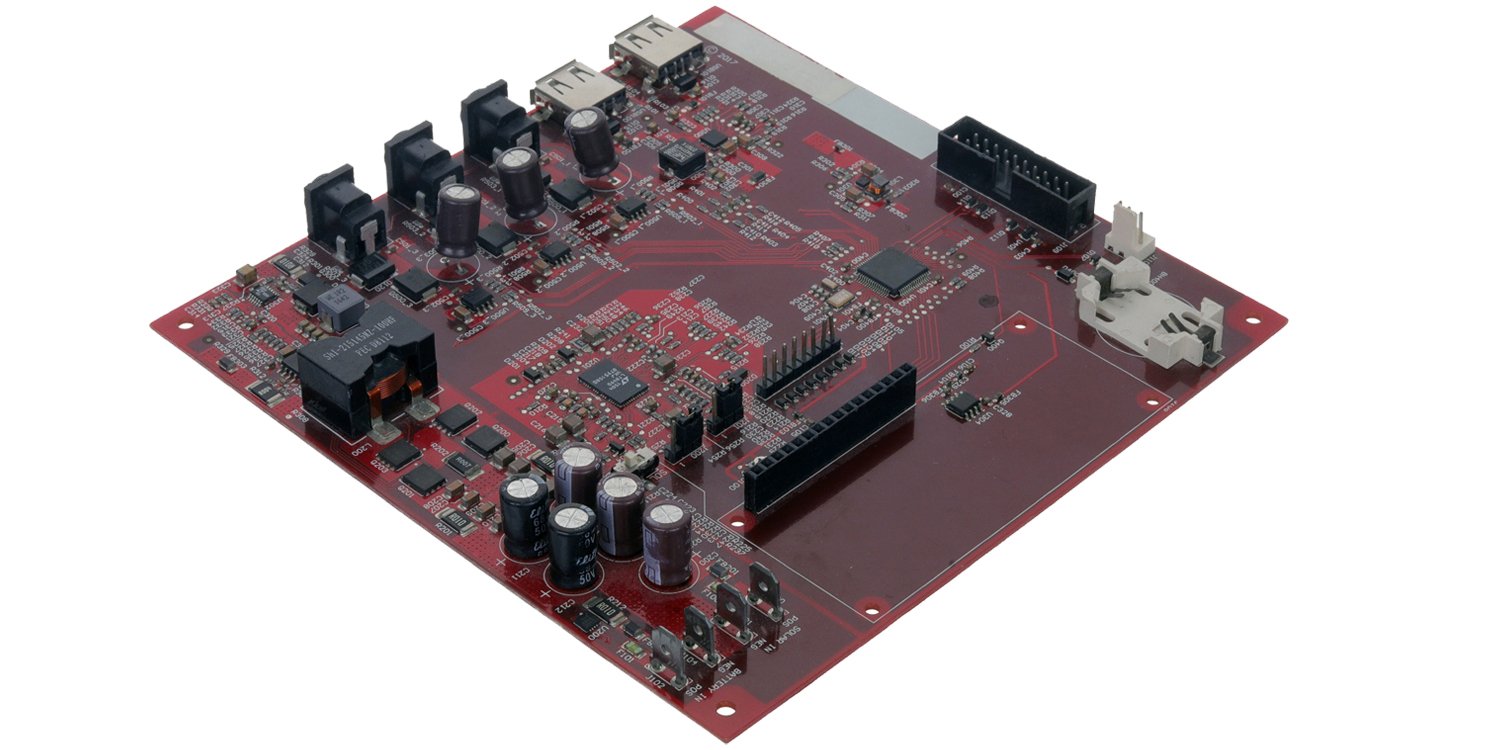

Chinese PCB assembly refers to the comprehensive process of manufacturing printed circuit boards and assembling electronic components in China’s advanced manufacturing facilities. Moreover, this process includes everything from PCB fabrication to component placement, soldering, and final testing.

The process typically involves several key stages:

- Vendor Qualification Process:

- Request facility certifications and audit reports

- Ask for customer references and case studies

- Start with small orders to evaluate performance

- Visit facilities when possible or use third-party auditors

- Comprehensive Documentation:

- Create detailed assembly instructions

- Specify exact component part numbers and suppliers

- Include acceptance criteria for all tests

- Document packaging and shipping requirements

- Quality Assurance Protocols:

- Implement incoming inspection procedures

- Request first article inspection reports

- Establish regular quality audits

- Use third-party inspection services when needed

- Legal Protection:

- Sign comprehensive non-disclosure agreements

- Include IP protection clauses in contracts

- Consider registering designs in China

- Work with legal experts familiar with Chinese law

- ❌ Unusually low prices: May indicate quality compromises or hidden costs

- ❌ Poor communication: Delayed responses or unclear answers to technical questions

- ❌ No certifications: Lack of ISO or industry-specific quality certifications

- ❌ Reluctance to provide references: Unwillingness to share customer testimonials

- ❌ No quality documentation: Cannot provide process control or inspection procedures

- ❌ Pressure for immediate decisions: Rushing you without allowing proper evaluation time

- Cost per board: $50-$200

- Setup costs: High impact

- Component costs: Retail pricing

- Lead time: 1-2 weeks

- Best for: Prototypes, testing, low-volume products

- Cost per board: $5-$50

- Setup costs: Minimal impact

- Component costs: Volume discounts

- Lead time: 3-4 weeks

- Best for: Production runs, commercial products

- Design for Manufacturing (DFM) Reviews: $200-$500 for complex designs

- First Article Inspection: $100-$300 per design

- Expedited Shipping: 3-5x normal shipping costs

- Customs and Duties: Variable by country and product classification

- Quality Escapes: Rework, scrap, and customer impact costs

- Currency Fluctuations: USD/CNY exchange rate changes

- Volume Consolidation: Combine multiple designs in single orders

- Flexible Timing: Avoid rush orders and plan for standard lead times

- Design Optimization: Minimize component count and use standard parts

- Long-term Partnerships: Build relationships for better pricing

- Alternative Components: Accept functionally equivalent substitutes

- CAGR: 4.1% compound annual growth rate

- Market Value: Expected to reach $54.6 billion by 2026

- Global Share: Maintaining >50% of worldwide production

- Technology Investment: $15+ billion in new equipment and facilities

- Smart pick-and-place systems

- AI-powered quality inspection

- Predictive maintenance algorithms

- Automated material handling

- High-frequency substrates for 5G

- Flexible-rigid combinations

- Thermal management materials

- Embedded component technology

- 01005 and smaller passive components

- Ultra-fine pitch connectors

- 3D packaging technologies

- System-in-package solutions

- Lead-free soldering processes

- Recyclable materials focus

- Energy-efficient manufacturing

- Waste reduction initiatives

- Electric Vehicles (EV):

- Battery management systems

- Motor control units

- Charging infrastructure

- Autonomous driving electronics

- 5G and IoT:

- Base station equipment

- Smart sensor assemblies

- Edge computing devices

- Connected home appliances

- Medical Electronics:

- Wearable health monitors

- Diagnostic equipment

- Telemedicine devices

- Implantable electronics

- Renewable Energy:

- Solar inverter systems

- Wind turbine controllers

- Energy storage systems

- Smart grid equipment

- ✅ China offers unmatched scale and capability – with $44+ billion in industry value and advanced manufacturing technology

- ✅ Quality depends on partner selection – look for ISO certifications, advanced testing equipment, and proven track records

- ✅ Cost optimization requires strategy – volume consolidation, design optimization, and long-term partnerships yield the best results

- ✅ Communication and documentation are crucial – clear specifications prevent costly mistakes and delays

- ✅ The future is bright – 4.1% CAGR growth and continued technological advancement make Chinese PCB assembly a smart long-term choice

Red Flags to Watch For

Be cautious when evaluating potential Chinese PCB assembly partners if you notice these warning signs:

Success Story: Companies like Apple and Tesla have successfully partnered with Chinese manufacturers by implementing rigorous supplier qualification and ongoing monitoring processes.

Chinese PCB Assembly Cost Breakdown

Understanding the cost structure of Chinese PCB assembly helps you budget effectively and identify opportunities for optimization. Furthermore, transparent pricing enables better decision-making for your projects.

Pricing Factors That Affect Your Total Cost

| Cost Factor | Impact Level | Typical Range | Optimization Tips |

|---|---|---|---|

| PCB Fabrication | High | $0.50-$50 per board | Optimize layer count, use standard materials |

| Component Costs | Very High | 60-80% of total cost | Volume purchasing, alternative sourcing |

| Assembly Labor | Medium | $5-$25 per board | Design for manufacturability |

| Testing & QC | Medium | $2-$15 per board | Define essential tests only |

| Tooling & Setup | Low | $200-$2000 one-time | Amortize over larger quantities |

| Shipping & Logistics | Low-Medium | 3-8% of order value | Consolidate shipments, use sea freight |

Small Batch vs. Large Volume Comparison

The economics of Chinese PCB assembly change dramatically with volume. Therefore, understanding these differences helps with planning and budgeting:

📦 Small Batch (10-100 boards)

🏭 Large Volume (1000+ boards)

Hidden Costs to Consider

Many companies overlook these additional costs when budgeting for Chinese PCB assembly projects:

Cost Optimization Strategies

Smart companies use these strategies to optimize their Chinese PCB assembly costs without compromising quality:

Cost Savings Tip: Companies typically save 15-25% by working with experienced Chinese PCB assembly partners who can suggest design improvements and component alternatives. Learn more about cost optimization at EMS Parts & Components.

Future of Chinese PCB Assembly (2025-2028 Forecast)

The Chinese PCB assembly industry continues to evolve rapidly, driven by technological advancement and changing market demands. Moreover, understanding future trends helps companies make strategic decisions about manufacturing partnerships.

Industry Growth Projections

Despite short-term market corrections, the long-term outlook for Chinese PCB assembly remains strong:

📈 Key Growth Metrics (2025-2028)

Emerging Technology Trends

Several technological developments are shaping the future of Chinese PCB assembly:

🤖 AI and Automation

🔬 Advanced Materials

⚡ Miniaturization

🌱 Sustainability

Market Opportunities

Key sectors driving demand for Chinese PCB assembly services include:

Challenges and Adaptations

The Chinese PCB assembly industry faces several challenges that are driving innovation:

| Challenge | Industry Response | Timeline |

|---|---|---|

| Rising Labor Costs | Increased automation and AI integration | 2024-2026 |

| Environmental Regulations | Green manufacturing initiatives | Ongoing |

| Supply Chain Volatility | Diversified sourcing strategies | 2025-2027 |

| Technology Complexity | Advanced equipment investments | 2024-2028 |

These trends indicate that Chinese PCB assembly will continue to be a critical manufacturing hub, but with increased focus on quality, sustainability, and technological advancement. Companies partnering with forward-thinking manufacturers like those certified to international standards will be best positioned for future success.

Industry Insight: According to IPC International, companies that invest in long-term partnerships with Chinese PCB assembly providers are 40% more likely to achieve their cost and quality objectives.

Conclusion: Your Next Steps in Chinese PCB Assembly

Throughout this comprehensive guide, we’ve explored the vast landscape of Chinese PCB assembly – from understanding the industry’s massive 54% global market share to navigating the practical steps of placing your first order. Moreover, we’ve covered the critical quality standards, cost optimization strategies, and future trends that will shape your manufacturing decisions.

Key Takeaways for Success

Remember these essential points as you move forward with your Chinese PCB assembly projects:

Why Choose Mustar for Your Chinese PCB Assembly Needs

At Mustar, we’ve been perfecting the art and science of PCB assembly for over 25 years. Furthermore, our commitment to excellence is demonstrated through:

🏆 Proven Excellence

Over 500 automotive PCBAs produced with IATF16949 certification

⚡ Fast Turnaround

PCB samples in 4-8 hours, production in 1-2 weeks

🔧 Advanced Capabilities

64-layer PCBs, 01005 components, 20 SMT lines

🌐 Global Reach

200+ suppliers, 100+ international sales professionals

Ready to Start Your Project?

Don’t let another day pass wondering about the potential of Chinese PCB assembly for your business. Therefore, take action today and discover how Mustar can transform your manufacturing strategy.

🚀 Get Your Free Quote Today!

Experience the Mustar difference – from prototype to production, we’re your trusted partner in Chinese PCB assembly excellence.

Join over 1000+ satisfied customers who trust Mustar for their Chinese PCB assembly needs. Your success story starts with a single click.

Ready to revolutionize your electronics manufacturing? Contact Mustar today and discover why we’re the preferred Chinese PCB assembly partner for companies worldwide. Whether you need a single prototype or millions of units, our team of 600+ professionals is ready to exceed your expectations.