Quick Summary: One-stop PCBA services can reduce your development costs by 10-15% and shorten product development cycles by up to 40%. Additionally, these services provide better quality control and simplified project management through a single point of contact.

Key Advantages at a Glance

| Advantage | Description | Industry Data / Statistic |

|---|---|---|

| Cost Savings | Bulk purchasing and consolidated shipping reduce overall costs | Component costs 10-15% lower via one-stop service |

| Time Efficiency | Parallel processing shortens development cycles | Development cycles shortened by 20-40% |

| Quality Improvement | Integrated testing reduces defects and rework | Reduced rework and warranty costs due to unified QC |

| Simplified Management | Single point of contact reduces project management time and errors | Project management time cut by up to 40% |

| Supply Chain Reliability | Experienced procurement teams secure authentic components and better pricing | Better pricing and availability through vendor relationships |

| Reduced Logistics Costs | Consolidated shipments reduce shipping fees and inventory transfers | Eliminated intermediate shipping steps |

When businesses need electronic circuit boards, they often face a difficult choice. Furthermore, they can work with multiple vendors for different services or choose a single provider for everything. However, the advantages of one-stop PCBA service are becoming clear as more companies discover the benefits.

Contents

- What is One-Stop PCBA Service?

- Cost Advantages of One-Stop PCBA Service

- Time Savings and Faster Lead Times

- Improved Quality Control and Reduced Errors

- Simplified Project Management and Communication

- Supply Chain and Component Procurement Benefits

- Scalability for Different Business Needs

- Industry-Specific Advantages

- FAQ Section

- Conclusion

What is One-Stop PCBA Service?

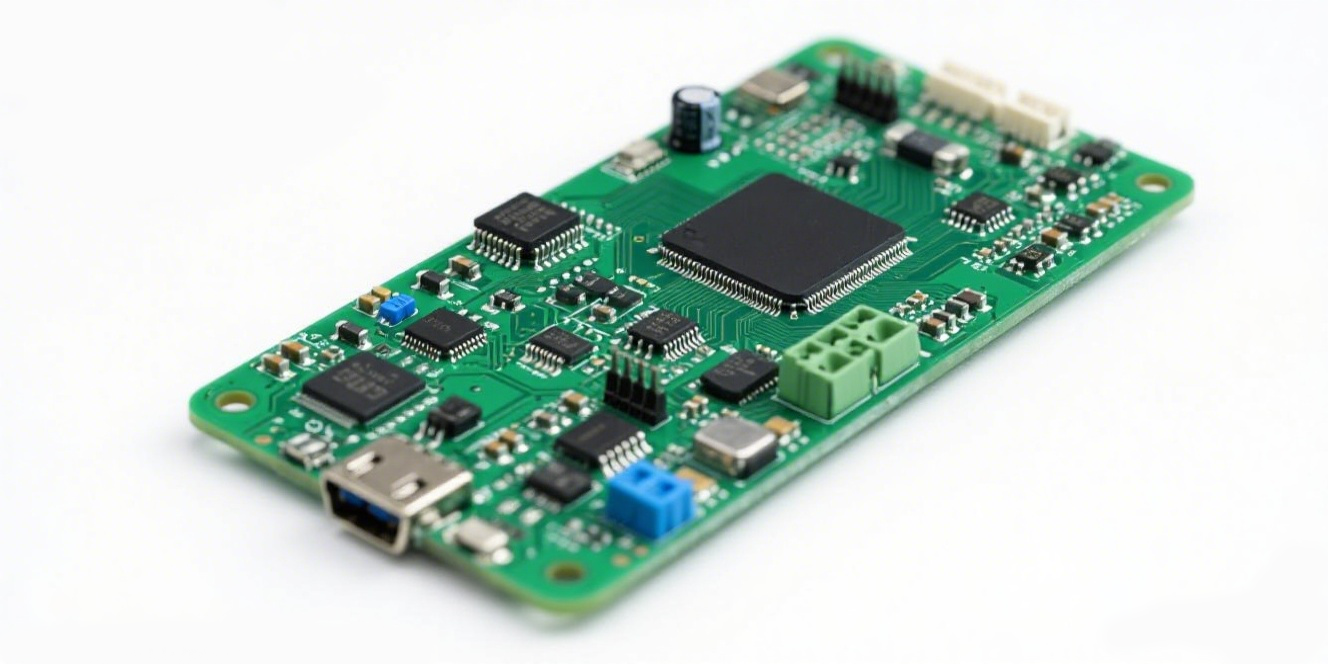

A one-stop PCBA service is a comprehensive manufacturing solution that handles every step of your circuit board project. Moreover, this service includes PCB fabrication, component procurement, assembly, testing, and final shipping. Instead of managing multiple vendors, you work with one experienced provider throughout the entire process.

Specifically, according to IPC standards, a complete one-stop service typically includes:

- Design review and optimization for manufacturability

- PCB fabrication from 1 to 64 layers using various materials

- Component sourcing with authentic parts verification

- SMT and through-hole assembly with advanced equipment

- Comprehensive testing including ICT, FCT, and AOI

- Final packaging and shipping to your location

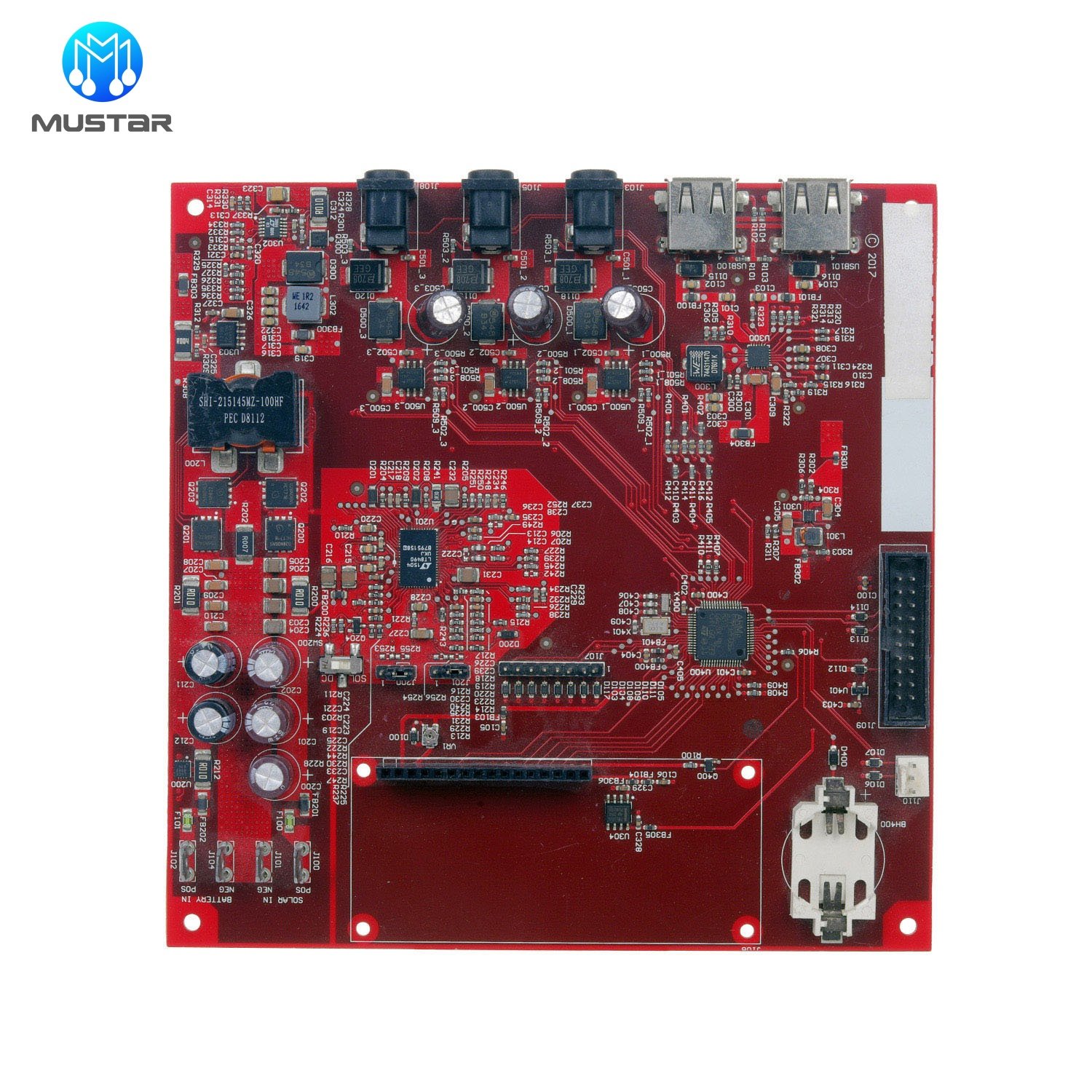

For example, companies like Mustar offer complete turnkey solutions with over 25 years of experience. Additionally, they provide specialized services for automotive, medical, and industrial applications.

Cost Advantages of One-Stop PCBA Service

The cost advantages of one-stop PCBA service are significant and measurable. First, bulk purchasing power allows providers to secure components at lower prices. Subsequently, these savings are passed on to customers.

Cost Savings Breakdown:

- Component costs reduced by 10-15% through bulk purchasing

- Shipping costs eliminated between multiple vendors

- Project management overhead reduced significantly

- Less administrative work and paperwork

Furthermore, industry research shows that companies using one-stop services typically save money in several ways. For instance, they avoid paying multiple setup fees and reduce inventory management costs.

Additionally, experienced providers like Mustar maintain relationships with over 200 global suppliers. Therefore, they can negotiate better prices and ensure component authenticity. This approach also reduces the risk of counterfeit parts, which can be costly to replace.

Time Savings and Faster Lead Times

Time efficiency is another major advantage of one-stop PCBA services. Research indicates that development cycles can be shortened by 20-40% when using integrated services. This improvement happens because multiple processes run simultaneously rather than sequentially.

For example, while PCB fabrication is happening, component procurement can occur at the same time. Moreover, this parallel processing approach eliminates waiting periods between different vendors. Consequently, your product reaches the market faster.

Furthermore, manufacturing studies demonstrate that integrated services provide several timing benefits:

- Faster design iterations with immediate feedback

- Quick prototype turnaround in as little as 4-8 hours

- Reduced communication delays between different vendors

- Streamlined approval processes with one decision maker

Additionally, when changes are needed, one-stop providers can implement them quickly across all processes. This flexibility is especially important in fast-moving industries like automotive and medical devices.

Improved Quality Control and Reduced Errors

Quality control improvements represent one of the most important advantages of one-stop PCBA services. When all processes happen under one roof, quality standards remain consistent throughout production. Moreover, this unified approach reduces errors and defects significantly.

Professional one-stop providers use advanced testing equipment to ensure quality. For instance, Mustar employs multiple testing methods including:

- 3D SPI (Solder Paste Inspection) for precise solder application

- 3D X-Ray inspection for hidden solder joints

- AOI (Automated Optical Inspection) for component placement

- ICT and FCT testing for functional verification

Quality Benefits: Integrated quality control reduces rework costs and warranty claims. Additionally, consistent standards across all processes eliminate quality gaps between different vendors.

Furthermore, quality management research shows that unified quality systems provide better traceability. Therefore, if issues arise, they can be quickly identified and resolved.

Moreover, industry certifications like ISO9001, IATF16949 for automotive, and ISO13485 for medical devices ensure compliance with strict quality requirements. These certifications give customers confidence in product reliability and safety.

Simplified Project Management and Communication

The simplified project management advantage of one-stop PCBA service cannot be overstated. Instead of coordinating with multiple vendors, you work with a single point of contact. Consequently, this approach reduces project management time by up to 40%.

Moreover, clear communication channels eliminate confusion and miscommunication. When problems arise, you know exactly who to contact for resolution. This streamlined approach is especially beneficial for complex projects with tight deadlines.

Additionally, experienced providers offer dedicated project managers and international sales teams. For example, Mustar employs over 100 international sales professionals who understand different market requirements. Therefore, communication barriers are minimized.

Project management studies indicate that simplified communication structures provide several benefits:

- Faster decision making with clear accountability

- Reduced administrative overhead and paperwork

- Better project visibility and progress tracking

- Quicker issue resolution with direct communication

Supply Chain and Component Procurement Benefits

Supply chain advantages represent a critical benefit of one-stop PCBA services. Professional providers maintain extensive supplier networks and experienced procurement teams. For instance, Mustar works with over 200 stable global suppliers and employs 50+ component sourcing engineers.

Furthermore, these relationships enable better component pricing and availability. Experienced procurement teams can also identify cost-saving alternatives while maintaining quality standards. Additionally, they ensure component authenticity, which protects against counterfeit parts.

Procurement Advantages:

- Access to global supplier networks

- Professional sourcing teams with 10+ years experience

- Guaranteed authentic components with proper traceability

- Cost optimization through alternative sourcing options

Moreover, supply chain research demonstrates that strong supplier relationships provide several benefits. These include priority allocation during shortages and better technical support.

Additionally, professional procurement teams understand component lifecycle management. Therefore, they can recommend alternatives for obsolete parts and help with long-term availability planning.

Scalability for Different Business Needs

The scalability advantages of one-stop PCBA services benefit both small startups and large enterprises. Small companies gain access to advanced manufacturing capabilities without large investments. Meanwhile, large companies benefit from flexible capacity and efficient processes.

For startups, one-stop services provide several key benefits:

- Low minimum order quantities for prototyping

- Technical support for design optimization

- Reduced complexity in vendor management

- Cost-effective solutions for small volumes

Furthermore, large enterprises benefit from scalable capacity and volume production capabilities. For example, Mustar operates a 12,000 square meter facility with over 600 employees. Therefore, they can handle both prototype runs and large volume production efficiently.

Additionally, manufacturing flexibility studies show that scalable services provide competitive advantages. Companies can respond quickly to market changes without capacity constraints.

Industry-Specific Advantages

Industry-specific advantages make one-stop PCBA services especially valuable for specialized applications. Different industries have unique requirements for quality, certification, and performance. Therefore, experienced providers offer tailored solutions for each sector.

Automotive Industry Benefits

The automotive sector requires strict quality standards and certifications. One-stop providers like Mustar offer IATF16949 certified production lines specifically for automotive applications. Moreover, they have produced over 500 types of automotive PCBA, including:

- Motor driver PCBA for electric vehicles

- Car audio systems with advanced features

- Driver assistance systems for safety applications

- Bus electronics for commercial vehicles

Medical Device Advantages

Medical applications require ISO13485 certification and strict quality control. Furthermore, one-stop providers understand medical device regulations and compliance requirements. For example, specialized PCBA for:

- Respiratory equipment control boards

- B-ultrasound systems with high precision

- Smart blood pressure monitors with connectivity

- Multifunctional medical instruments

Additionally, FDA guidelines emphasize the importance of quality systems in medical device manufacturing. One-stop providers with proper certifications ensure compliance with these requirements.

FAQ Section

Conclusion

The advantages of one-stop PCBA service are clear and measurable. From 10-15% cost savings to 20-40% shorter development cycles, these services provide significant business benefits. Moreover, improved quality control, simplified project management, and reliable supply chains make one-stop services the smart choice for modern electronics manufacturing.

Furthermore, industry-specific expertise ensures that your products meet all necessary standards and certifications. Whether you’re developing automotive electronics, medical devices, or industrial equipment, experienced one-stop providers have the knowledge and capabilities you need.

Ready to Experience the Advantages of One-Stop PCBA Service?

Join over 100 automotive electronics enterprises and countless other companies who have accelerated their growth with professional PCBA manufacturing. Get expert consultation, competitive pricing, and reliable delivery schedules.

Contact Mustar today for your free quote and discover how one-stop PCBA service can transform your product development process.

Get Your Free Quote Now✓ 25+ Years Experience ✓ ISO Certified ✓ Global Shipping ✓ Expert Support

Mustar projects: