🚀 Quick Key Takeaways

The new energy PCBA market is exploding! From $3.5 billion in 2024 to a projected $10.2 billion by 2033, that’s a massive 12.5% growth rate annually. Here’s what you need to know right now:

| Key Metric | Current Value (2024) | Future Projection | Why It Matters |

|---|---|---|---|

| New Energy Vehicle PCB Market | $3.5 Billion | $10.2 Billion by 2033 | 12.5% annual growth – massive opportunity |

| Global PCB Market Size | $73 Billion | $90.4 Billion by 2028 | Steady 5.4% growth across all sectors |

| Multilayer PCB Share | 38.2% of global output | 4.4% CAGR through 2028 | Advanced designs becoming standard |

| Key Requirement | RoHS-compliant materials | Environmental compliance is mandatory | |

The new energy revolution is happening right now, and PCBA (Printed Circuit Board Assembly) sits at the heart of every breakthrough. Whether you’re developing electric vehicles, solar systems, or energy storage solutions, understanding these key considerations will make or break your project’s success.

Contents

Why PCBA Matters in New Energy Systems

Think of PCBA as the brain and nervous system of new energy applications. Just like how your smartphone needs perfectly designed circuits to function, renewable energy systems depend entirely on high-quality PCBA to convert, store, and manage power efficiently.

Moreover, the numbers tell an incredible story. The global PCB market research shows that new energy applications are driving unprecedented growth. Furthermore, electric vehicles alone are creating massive demand for specialized PCBA solutions.

Additionally, Mustar’s 25+ years of experience in PCBA manufacturing has shown us that new energy applications have unique requirements. These systems must handle extreme conditions while maintaining perfect reliability. As a result, traditional PCBA approaches simply won’t work.

Critical Design Challenges You Must Address

What are the main challenges in designing PCBA for new energy applications? Based on industry research and real-world experience, there are three critical challenges that can make or break your project:

High-Current and High-Voltage Design Considerations

New energy systems typically handle much higher power levels than traditional electronics. For instance, electric vehicle chargers can operate at voltages exceeding 800V with currents reaching hundreds of amperes. Consequently, your PCBA design must account for:

- Proper trace width calculations to handle high currents without overheating

- Adequate spacing between components to prevent electrical arcing

- Robust grounding systems to ensure safety and performance

- Component selection rated for the specific voltage and current requirements

Thermal Management Challenges in New Energy PCBA

Why is thermal management important in PCBA for renewable energy? Simply put, heat is the enemy of reliability. High currents generate significant heat that can degrade performance and reduce component lifespan dramatically.

“Effective thermal management isn’t optional in new energy applications – it’s absolutely critical for maintaining safe operating temperatures and ensuring long-term reliability.” – Electronics Cooling Research

Therefore, successful thermal management strategies include:

- Heat sinks and thermal vias to dissipate heat efficiently

- High thermal conductivity materials like aluminum-backed PCBs

- Strategic component placement to minimize hot spots

- Active cooling solutions when necessary

Environmental and Mechanical Stress Factors

New energy systems often operate in harsh environments. For example, solar inverters face extreme temperature cycles, while electric vehicle PCBA must withstand constant vibration and shock. As a result, your design must consider:

- Temperature cycling resistance from -40°C to +125°C

- Humidity and corrosion protection for outdoor installations

- Mechanical shock and vibration tolerance especially for mobile applications

- UV resistance and weatherproofing for solar applications

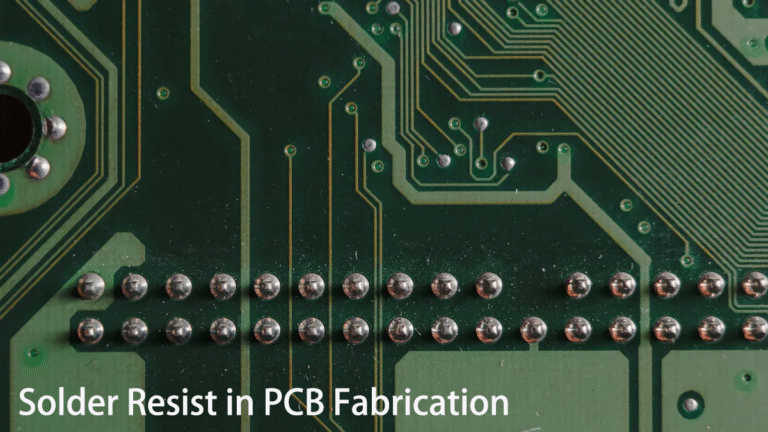

Smart Material Selection for Long-Term Success

What materials should be used for PCBA in new energy applications? The answer depends on your specific requirements, but there are universal principles that apply to all new energy PCBA projects.

Material Selection for New Energy PCBA: Sustainability and Durability

First and foremost, environmental compliance is non-negotiable. All materials must comply with RoHS standards and demonstrate high thermal and chemical stability. Additionally, sustainable material choices align with the environmental goals of new energy applications.

Pro Tip: Mustar’s component sourcing team works with 200+ global suppliers to ensure 100% RoHS compliance while optimizing costs. This approach guarantees both environmental responsibility and project success.

Key material considerations include:

- FR-4 with high Tg ratings for standard applications requiring thermal stability

- Aluminum-backed PCBs for superior thermal management in power applications

- Rogers materials for high-frequency applications like wireless charging systems

- Flexible-rigid combinations for space-constrained designs with movement requirements

Furthermore, advanced PCB materials research shows that proper material selection can extend product lifespan by 300% or more in demanding applications.

Proven Strategies for Reliable New Energy PCBA

How can reliability and quality be ensured in PCBA for energy applications? The answer lies in implementing comprehensive quality control measures and rigorous testing protocols from the very beginning of your project.

Quality Control and Reliability Testing for New Energy PCBA

Reliability isn’t something you can add later – it must be built into every step of the manufacturing process. Specifically, Mustar’s quality control approach includes multiple checkpoints to ensure consistent results:

Essential quality control strategies include:

- First Article Inspection (FAI) to validate the initial production setup

- In-Circuit Testing (ICT) to verify component placement and values

- Functional Circuit Testing (FCT) to ensure proper system operation

- 3D SPI and AOI inspection to catch defects before they become problems

- Thermal cycling tests to simulate long-term environmental stress

Moreover, advanced testing methodologies like accelerated life testing can predict product performance over 20+ year lifespans. This approach is particularly important for solar and wind energy applications where replacement costs are extremely high.

Integration and Scalability of PCBA in Energy Systems

Modern new energy systems require seamless integration between multiple PCBA modules. Therefore, designing for scalability from the beginning saves significant time and money during production scaling.

Key scalability considerations include:

- Modular design approaches that allow easy system expansion

- Standardized interfaces for plug-and-play functionality

- Future-proof communication protocols like CAN bus and Ethernet

- Flexible manufacturing processes that adapt to volume changes

Real-World Applications: Where New Energy PCBA Shines

How is PCBA used in new energy vehicle applications? The applications are incredibly diverse and growing rapidly. Let’s explore the most important ones that are driving the 12.5% annual growth rate.

Electric Vehicle Systems

Electric vehicles represent the largest growth segment in new energy PCBA applications. These systems require multiple specialized PCBA modules working together seamlessly:

- Battery Management Systems (BMS) – Monitor cell voltages, temperatures, and charging states

- Motor Control Units – Convert DC power to AC for efficient motor operation

- Onboard Chargers – Manage power conversion from AC grid to DC battery

- DC-DC Converters – Step down high voltage for auxiliary systems

- Vehicle Control Units – Coordinate all vehicle systems and communication

Notably, Mustar has produced over 500 types of automotive PCBA and holds IATF16949 certification, ensuring the highest quality standards for safety-critical applications.

Solar Inverters and Energy Storage Solutions

Solar energy systems depend on sophisticated PCBA for power conversion and system management. Furthermore, energy storage systems require advanced battery management and grid-tie functionality.

Critical applications include:

- String inverters for residential solar installations

- Central inverters for utility-scale solar farms

- Micro-inverters for maximum panel-level optimization

- Energy storage inverters for battery backup systems

- Grid management systems for smart grid integration

Cost Optimization Strategies for New Energy PCBA Manufacturing

While quality and reliability are paramount, cost optimization remains crucial for market competitiveness. Smart cost reduction strategies include:

- Design for Manufacturing (DFM) to minimize production complexity

- Component standardization to leverage volume purchasing power

- Alternative sourcing for equivalent components at lower costs

- Test optimization to reduce testing time while maintaining quality

- Yield improvement through process optimization and defect prevention

For example, Mustar’s professional BOM management and global supplier network often achieve 15-25% cost reductions without compromising quality or performance.

Future-Proofing Your New Energy PCBA Strategy

What future trends are expected in PCBA for new energy? The industry is evolving rapidly, and staying ahead of these trends is essential for long-term success.

Future Trends and Innovation in PCBA for New Energy Applications

Several key trends are reshaping the new energy PCBA landscape:

- AI and IoT integration for predictive maintenance and smart energy management

- Wide bandgap semiconductors like SiC and GaN for higher efficiency

- Wireless power transfer systems for convenient EV charging

- Vehicle-to-Grid (V2G) technology for bidirectional power flow

- Advanced materials for extreme environment applications

Additionally, the integration of artificial intelligence in energy systems is creating new opportunities for predictive analytics and autonomous optimization.

🔮 Looking Ahead: The Next 5 Years

Industry experts predict that multilayer PCBs will dominate new energy applications due to their superior performance in high-power, high-frequency environments. Companies that invest in advanced PCB technologies now will have significant competitive advantages.

Moreover, sustainability requirements are becoming stricter. Future PCBA designs must consider end-of-life recycling, reduced material waste, and carbon footprint optimization throughout the entire product lifecycle.

Conclusion: Your Next Steps to New Energy PCBA Success

The new energy PCBA market is experiencing explosive growth, but success requires careful attention to critical design considerations. From thermal management and material selection to quality control and future-proofing strategies, every decision impacts your project’s long-term viability.

Remember these key takeaways:

- Market opportunity is massive – $10.2 billion by 2033 with 12.5% annual growth

- Thermal management isn’t optional – it’s critical for reliability and safety

- Material selection affects everything – choose RoHS-compliant, high-performance options

- Quality control must be comprehensive – test early, test often, test thoroughly

- Future trends favor advanced technologies – multilayer PCBs and AI integration

Most importantly, partnering with an experienced manufacturer makes all the difference. The complexity of new energy applications requires deep expertise, advanced equipment, and proven quality systems.

🚀 Ready to Accelerate Your New Energy PCBA Project?

Don’t let complex design challenges slow down your breakthrough innovation.

Mustar’s 25+ years of experience, IATF16949 and ISO13485 certifications, and state-of-the-art facility with 20 SMT lines are ready to transform your new energy vision into reality.

✅ Free DFM Review – Optimize your design before production

✅ 4-8 Hour Sample Turnaround – Accelerate your time-to-market

✅ 200+ Global Suppliers – Ensure component availability and cost optimization

✅ Comprehensive Testing – ICT, FCT, 3D X-Ray, and more

Get Your Free PCBA Quote Today →

Join 100+ automotive and renewable energy companies who trust Mustar for their critical PCBA needs.