Contents

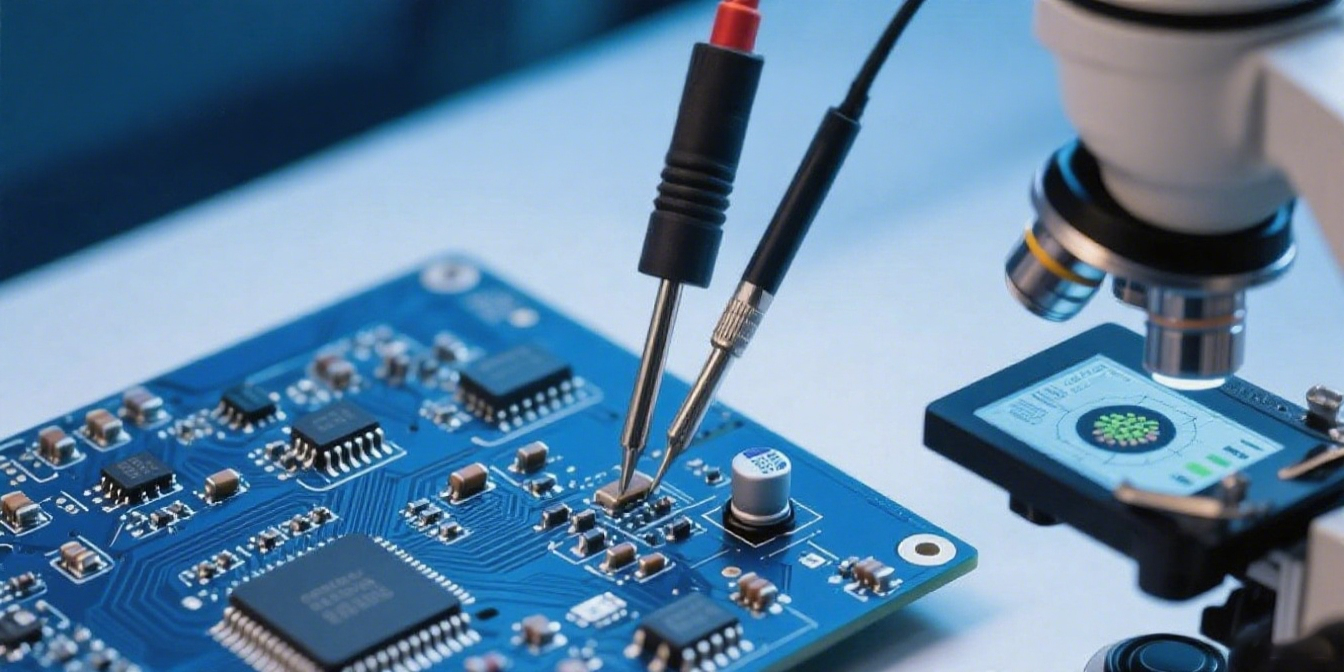

Why PCBA testing is important beyond final inspection

In a rapidly evolving industry like electronics, PCBA test is more than just a quality checkpoint. It reflects the rigor of the manufacturing process and the control. According to studies, about 30% of PCBAs fail due to inadequate testing. Mustar embeds comprehensive PCBA test protocols in every stage of production, enabling early defects detection and reducing the failure rate by up to 40 percent. This integration of testing and production allows for early detection of defects, which reduces costly rework while increasing product reliability.

PCBA Testing Methods: Overview and Functions

Understanding the strengths and application of different PCBA test methods can optimize quality control and production efficiency.

1. Automated Optical Inspection

AOI utilizes high-resolution cameras, intelligent algorithms, and other tools to detect visible defects, such as component misplacement and solder bridging.

-

Coverage: 85%-95% of visible defects

-

Detection rate: 90-98%

-

Test Duration: 30-60 Seconds per board

-

The role of Real-time surface monitoring in high-density assemblies.

2. In-Circuit Test (ICT)

ICT uses “bed of nail” fixtures to verify electrically circuit connectivity and component parameter values, identifying any shorts, open circuits, or incorrect component values.

-

Detection rate: 95-999%

-

Precision: High precision in parameter measurements

-

Role : Assures electrical integrity and is suitable for mass production.

3. Functional Test (FCT)

FCT tests the PCBAs’ real-world performance, simulating conditions of operation, system functions, communication and adaptability to environmental changes.

-

Coverage : 100% Functional Verification

-

Quality Assurance >99.5% reliability

-

Role Final performance verification, crucial for complex and highly reliable products.

4. AXI (X-ray inspection)

AXI detects defects such as voids and bridging that are invisible to optical methods.

-

Detection Rate: 98-99.5% for hidden defects

-

Role essential for sectors with high reliability such as automotive and medical.

5. Flying Probe Test

Flying probe tests are ideal for prototyping and small batches. They offer micron-level accuracy, flexibility, and can be performed without the need of dedicated fixtures.

-

Role: Rapid verification during design iteration and low-volume production.

6. Boundary Scan test

Boundary scan testing digital interconnects is based on IEEE 1149.1 and supports online programming via JTAG.

-

Role : Efficiently test complex digital systems without physical contact.

FAQs

-

What is the difference between ICT and a FCT?

ICT focuses on electrical connections and component parameters to detect manufacturing defects. FCT measures the actual performance of the circuit under real-world conditions.

-

How to calculate PCBA test cost?

The cost of a method and its complexity can vary. AOI can cost as little as 0.05-0.15 RMB for each board while FCT costs between 0.50-2.00 RMB. The cost of testing is typically 5-15% but it prevents expensive field failures.

-

When should you use X-ray tests?

AXI is essential in the automotive, medical and aerospace industries that require high reliability, for BGA, QFN and other hidden solder joint types.

-

Typical defect coverage rates?

AOI covers 85-95% visible defects, ICT covers 90-95% electrical issues, FCT covers 100% functional aspects.

-

How much time does PCBA testing require?

AOI: 30-60 sec/board, ICT: 60 – 180 sec, FCT: 2- 5 mins; Flying probe 3-10 minutes.

-

Common PCBA defects?

Electrical shorts/opens (between 15-20%) and component parameter deviations (10-15%) are the most common problems.

-

Is PCBA testing mandatory?

It is not necessary to comply with legal requirements for all products, but many are required by industry standards (e.g. IEC 60601 in medical devices, AEC Q100 for automotive).

Test Accuracy and Production Process Control

While each test method has its own unique role, accuracy and effectiveness in PCBA testing are heavily dependent on the quality and consistency of the manufacturing process . As an example:

Our automated production lines guarantee precise component placement, soldering quality and reduce false positives during Functional Testing (FCT).

Integrating real time AOI during production allows for early detection of surface defects and electrical faults, preventing boards from progressing to later stages.

We can maintain a defect-rate well below the industry average, reduce rework and speed up time-to market by tightly coupling manufacturing and testing.

Mustar is a PCBA partner that you can trust because of its process-driven quality assurance.

How to choose the right PCBA manufacturer: Key indicators

Consider these factors when choosing a PCBA manufacturer:

Comprehensive testing protocols: Search for providers that combine AOI testing, ICT testing, and functional tests seamlessly in production lines.

Transparent, detailed reporting of test results: Full access to test data allows you to track trends and make informed decisions.

Scalable Manufacturing Capabilities: Ability to support your product, from prototype to mass production, without compromising on quality or delivery.

Mustar is a leader in these areas. We offer a complete range of testing equipment and certified quality systems, including ISO 9001, IATF 16949 and ISO 13485, as well as global service expertise.

Build Quality From the Start

PCBA testing is a vital part of ensuring the quality and reliability of electronic products. Combining multiple testing methods within a tightly controlled manufacturing process can help companies minimize defects, lower costs and improve customer satisfaction.

We integrate advanced PCBA tests with superior production controls to deliver high-quality, consistent assemblies that meet your requirements.

Want to elevate your product’s quality with a partner that builds quality into the process from the very beginning? Contact us to find out how we can customize our testing and production processes to ensure your success.

Mustar projects: