Contents

- What is PCB Board Assembly?

- PCB Assembly Process: Step by Step

- Key PCB Board Assembly Technologies

- PCB Assembly Market Trends & Forecast Growth

- PCB Assembly in Industry

- Assuring quality in PCB Assembly

- Common PCB Assembly Challenges

- Why choose Mustar PCB Assemblys?

- AI and Automation: The Future of PCB Board Assembly

- FAQs (Frequently Asked Questions)

- The Conclusion

What is a PCB Board Assembly?

The PCB board assembly process involves mounting electronic components on a blank printed-circuit board (PCB), to create an electronic assembly. Soldering precisely is required to ensure that devices, from smartphones to automotive systems, work reliably.

Assembly is typically comprised of:

Component positioning Placing electronic components on the PCB with accuracy

Soldering Soldering and heat to permanently attach components

Testing Verifying that the board is assembled correctly

Quality control Assuring that the assembly meets all requirements

*Learn more about PCB assembly basics from IPC Association Connecting Electronics Industries.*

PCB Assembly Process: Step by Step

1. Design Review and Preparation

Engineers review PCB files before production and prepare production lines by gathering all components necessary to ensure smooth assembly.

2. Solder Paste Application

Solder paste is applied using precision stencils to the PCB pads that will hold the components.

3. Component Placement

Pick-and-place robots can position parts with accuracy and speed, even if they are as small as 0.2mm.

4. Reflow Soldering

The PCB is passed through a reflow-oven where the solder paste melts and creates permanent electrical connections.

5. Inspection & Testing

To ensure that every board meets the quality standards, teams of quality experts use automated optical inspection and functional testing.

*For a detailed PCB assembly process overview, visit EMA Design Automation.*

Key PCB Board Assembly Technologies

Surface Mount Technology (SMT)

The PCB surface can be used to mount components directly. Space efficiency, cost effectiveness, and automation are all benefits.

Through-Hole Technology

The components are inserted into the holes of the PCB, and then soldered from the other side. This method is perfect for high-power components and provides strong mechanical connections.

Mixed Technology

Combining SMT and THT for maximum performance and flexibility. Mustar is a specialist in mixed-technology complex assemblies.

Explore SMT vs THT on Venture Electronics blog.

PCB Assembly Market Trends & Forecast Growth

Global PCB Assembly Market is Growing Rapidly, Driven by Technological Advancements and Increasing Demand across Industries

| Year | Market Size (USD Billions) | CAGR (%) | Key Drivers |

|---|---|---|---|

| 2023 | $9.1 | – | Aerospace and Automotive |

| 2025 | $90.91 | 4.7 | Electric Vehicles, 5G, IoT |

| 2035 | $147.5 | 4.7 | Smart Devices, AI Hardware |

Source: Archivemarketresearch, PRNewswire, Dataintelo

PCB Assembly in Industry

Consumer Electronics Smartphones, wearables and smart home devices

Automobile ADAS and infotainment system for electric vehicles

Medical Devices : Diagnostic equipment, implantable devices

Industrial Automation Robotics and sensor networks. Power management.

Assuring quality in PCB Assembly

Mustar ensures quality through:

Automated Optical Inspect (AOI)

In-Circuit Testing (ICT)

Functional Testing

To ensure reliability and safety, we adhere to international standards such as ISO 9001 and IATF 16949.

Common PCB Assembly Challenges

Component Shortages We have strong relationships with our suppliers and manage inventory well.

Miniaturization High-density designs are handled by advanced placement and inspection equipment.

Thermal Management Heat dissipation and strategic component layout solutions.

Quality Consistency Continuous process improvement and training.

Solutions to PCB assembly challenges can be found at Assembly Magazine.

Why choose Mustar PCB Assemblys?

Experience of 25 years and more than 5,000 successful projects

Manufacturing advanced with 16 SMT lines, including specialized automotive/medical lines

Deutsche Telekom is a trusted client in 98 countries.

From PCB production to packaging and final testing, we offer a comprehensive service.

Commitment to Innovation with AI and Industry 4 integration

AI and Automation: The Future of PCB Board Assembly

Mustar invests cutting-edge technology such as:

AI-powered predictive maintenance and defect detection

Smart factory systems and collaborative robots

Cloud computing and Industry 4.0 data analytics

Blockchain, 3D printing and augmented reality are all emerging technologies

Discover how AI is transforming PCB assembly at EE Times.

FAQs (Frequently Asked Questions)

Q1 : What’s the difference between THT and SMT in PCB assembly

A Surface Mount Technology (SMT) is a mounting technique that mounts components on the surface of the PCB. This allows for smaller, lighter designs, and automated production. THT (Through Hole Technology) inserts component lead through holes on the PCB. This provides stronger mechanical bonds, and allows for better heat dissipation.

Q2 – How long does it take to assemble a PCB?

A : Timeline depends on the project’s complexity and volume. While prototyping may take only a few hours, large-scale production can require weeks. Mustar provides rapid prototyping with 7×24 support from engineers to help you meet your deadline.

Q3 – What standards of quality does Mustar adhere to?

A Mustar adheres to ISO 9001 (automotive), IATF 16949 standards (medical), ISO 13485 standards (medical), as well as IPC-A 610 standards (to ensure high-quality PCB assemblies).

Q4 Can Mustar handle mixed-technology PCB assemblies?

A Mustar is a specialist in mixed-technology assemblies, combining THT and SMT, for high-reliability and complex applications.

Q5 – How does Mustar deal with component shortages and supply chain issues?

A. Mustar has strong supplier relationships and multiple sourcing channels. Inventory management is also used to ensure a steady supply.

The Conclusion

PCB board assembly, which is the cornerstone of modern electronic manufacturing, transforms bare circuit boards to sophisticated devices that are used in industries ranging from consumer electronics and automotive to medical. The market is set for strong growth driven by innovations in IoT and 5G hardware, electric vehicles, as well as AI.

It is important to choose the right PCB Assembly partner. Mustar is a leader in the industry with its 25 years of experience, manufacturing capabilities, global presence, commitment to innovation, and over 25 years’ experience. We are the perfect partner for bringing your electronic products efficiently to market. Our services, our strict quality control and our future-focused investment in AI and automation makes us the best choice.

Are you ready to begin your PCB assembly project now? Mustar offers expert assistance, quick turnaround and competitive pricing. Contact us today.

🚀 ARE YOU READY TO START?

Mustar combines 25+ years of PCBA expertise with specialized knowledge in new energy applications. Our certified manufacturing processes, advanced testing capabilities, and global supply chain ensure your project success.

Why Choose Mustar for Your PCBA?

- ✅ IATF16949 & ISO13485 certified quality systems

- ✅ Dedicated new energy production lines

- ✅ Advanced testing with 3D X-Ray and ICT/FCT

- ✅ 200+ global suppliers ensuring component availability

- ✅ Fast prototyping with 4-8 hour PCB samples

Contact Mustar today and discover how our PCBA expertise can accelerate your project from concept to market success

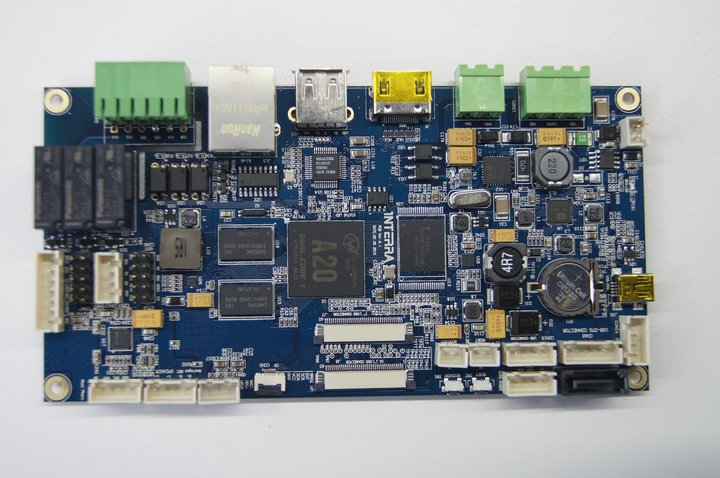

Mustar projects: