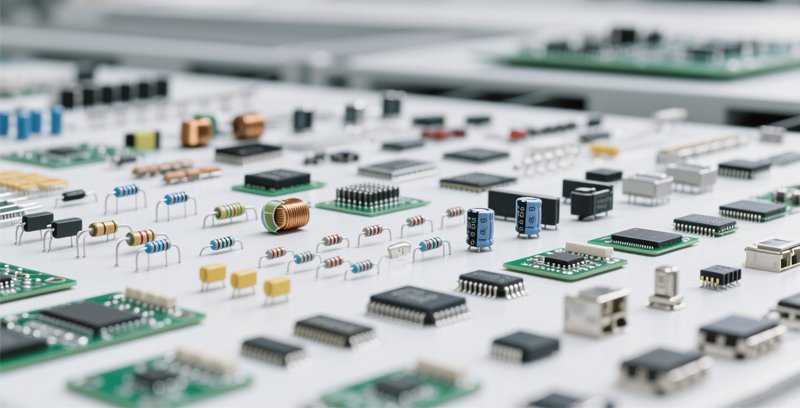

Electronic Components Sourcing BOM Service

Our Work For Components Sourcing

We specialize in sourcing authentic electronic components and optimizing your BOM with reliable alternatives. Backed by a global supply chain, engineering support, and strict inspection standards, our service helps ensure smooth PCBA production and cost-efficiency from prototype to mass manufacturing.

Component Sourcing & Supplier Network

We partner with authorized distributors like Digi-Key, Mouser, Arrow, and TTI to secure genuine components at competitive prices. Our global sourcing team ensures traceable, RoHS-compliant parts with full documentation and stable lead times—even during shortage seasons.

BOM Review & Optimization

Send us your BOM in Excel or CSV format—we’ll validate part numbers, flag obsolete items, and recommend compatible alternatives. This helps reduce cost, shorten lead time, and ensure smooth component availability before production.

Electronic Components & BOM Services

From sourcing authentic components to optimizing your BOM structure, our expert team ensures cost-efficient, on-time supply to keep your PCBA production running smoothly.

✅ Global Component Procurement

We maintain strong partnerships with over 100 global authorized suppliers, ensuring genuine and traceable parts—no clones, no counterfeits.

📋 BOM Cost Optimization

We review your Bill of Materials to reduce cost, replace obsolete parts, and improve compatibility without sacrificing performance.

🔎 Part Matching & Validation

Struggling with mismatched part numbers or sourcing shortages? We help match equivalents and provide datasheet verification before assembly.

Reliable Electronic Components & BOM Optimization

Sourcing quality components is critical to successful PCBA. At Mustar, we streamline the entire procurement process—from BOM review to global sourcing—ensuring every part is authentic, cost-effective, and ready for production.

- Authorized Component Sources Only — We partner with top-tier suppliers like Digi-Key, Mouser, and Arrow to ensure 100% original parts.

- BOM Engineering Support — Our engineers review your BOM for compatibility, availability, and suggest alternative components when needed.

- Cost Optimization — We help reduce overall BOM costs while maintaining the required specifications and performance.

- Lifecycle & Obsolescence Checks — Ensure long-term component availability and avoid end-of-life surprises.

- Fast Quotation & Sample Procurement — Speed up your project timeline with efficient component quoting and sourcing for prototypes.

Our Customers

Established Clients

Walmart

Partnered in OEM consumer electronics PCBA production with rapid lead times and cost-effective solutions.

Danfoss

Provided high-reliability PCBA for industrial control and HVAC systems, meeting strict European quality standards.

3B medical

Supplied precision PCBA for respiratory and sleep therapy devices, ensuring ISO 13485 medical compliance.

Q-loud

Delivered customized IoT control boards with secure communication protocols, supporting their smart home initiatives.

Chips Manufacturer Authorized Dealers

Chip Original Manufacturer supply component for us directly, ensure our quality and competitive.

Factory Overview

At present, our factory is 12,000 square meters with more than 600 employees (Including more than 100 professional International sales, more than 50 Components sourcing engineers with over 8 years’ experience, more than 50 Quality control personnel).

There are 20 SMT lines (6 SMT lines are specially used for the production of Medical and Automotive products), 2 Fast sample preparation lines, 5 DIP lines, 3 Post welding lines, 3 Assembly lines and 3 Test lines).

What People Think About Us

We are proud to earn the trust of our clients worldwide. Their feedback drives us to continuously deliver high-quality PCBA solutions, fast turnaround, and exceptional service for every project.

Mustar has been an outstanding partner for our PCBA needs. Their fast prototyping and consistent quality helped us speed up our product launches without any compromise on reliability.

We appreciate Mustar's flexibility and technical expertise. From small batches to large production runs, they always deliver high-quality PCBA assemblies on time and within budget.

Thanks to Mustar’s professional team and strict quality control, our medical devices have met international certification standards effortlessly. Highly recommended for any precision PCBA projects.

Get In Touch

Contact Us

sales@mustarpcba.com

Tel

+86 136 8883 2535

+ 1 (347) 718 9175

Address

#602 ~ 603, Building C, Qianwan Key & Core Technology Industrial Park, Bao'an District, Shenzhen China

Frequently Asked Questions

Yes,we support 3-7 days fast proofing.

Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process. All documents from customers are never shared with any third parties. NDA can be signed.

There is no MOQ. We are able to handle small as well as large volume production with flexibility. We have two fast proofing production lines.

We can offer OEM service including PCBA making, PCB assembly, components sourcing. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

ln order to guarantee PCB product quality,usually tested by flying probe; electrical fixture; automated optical inspection (AOI); X-ray inspection for BGA parts; first article inspection (FAl), and so on.

Gerber or Eagle, BOM listing, PNP and Components Position.