🔥 Key Takeaways: Custom PCB Assembly at a Glance

| Aspect | Key Information |

|---|---|

| Market Size | $36.3 billion in 2024, projected to reach $54.8 billion by 2033 |

| Cost Range | $3-$4 for simple boards to hundreds of dollars for complex designs |

| Growth Rate | 5.9% CAGR from 2026 to 2033 |

| Top Benefits | Tailored design, improved performance, cost efficiency, flexibility |

| Main Techniques | SMT, Through-hole, and Hybrid assembly methods |

Custom PCB assembly is revolutionizing how electronics manufacturers create innovative products. Furthermore, this specialized process offers unprecedented flexibility and performance advantages. In this comprehensive guide, we’ll explore everything you need to know about custom PCB assembly in 2025.

Contents

- What is Custom PCB Assembly?

- Market Insights: Custom PCB Assembly by the Numbers

- Top 7 Benefits of Custom PCB Assembly for Your Business

- Essential Custom PCB Assembly Techniques You Should Know

- The Custom PCB Assembly Process

- Cost Factors in Custom PCB Assembly

- How to Choose the Right Custom PCB Assembly Partner

- Future Trends in Custom PCB Assembly

- Real Success Stories: Custom PCB Assembly Case Studies

- Frequently Asked Questions About Custom PCB Assembly

What is Custom PCB Assembly? (Definition & Quick Overview)

Custom PCB assembly is the specialized process of manufacturing printed circuit boards tailored to specific design requirements. Unlike standard PCB assembly, this approach involves creating unique electronic solutions that perfectly match your project’s needs.

Additionally, custom PCB assembly differs from standard assembly in several key ways:

- Personalized Design: Every board is created specifically for your application

- Flexible Materials: Choose from various substrate materials like FR-4, aluminum, or Rogers

- Specialized Components: Incorporate unique or hard-to-find electronic components

- Custom Form Factors: Create boards in any shape or size needed

Moreover, businesses choose custom solutions when standard boards can’t meet their specific requirements. This approach is particularly valuable for specialized applications requiring unique functionality.

Market Insights: Custom PCB Assembly by the Numbers

The custom PCB assembly market is experiencing remarkable growth. Furthermore, understanding these statistics helps businesses make informed decisions about their electronics manufacturing strategies.

| Market Metric | 2024 Data | 2033 Projection | Growth Rate |

|---|---|---|---|

| Global PCB Assembly Market | $36.3 Billion | $54.8 Billion | 5.9% CAGR |

| HDI PCB Market | $25.2 Billion | $40.0 Billion | 6.8% CAGR |

| Asia-Pacific Market Share | 65% | 68% | Steady Growth |

“The custom PCB assembly market is driven by increasing demand for specialized electronics in automotive, medical, and IoT applications.” – Industry Report 2024

These numbers clearly show that custom PCB assembly is not just a trend. Instead, it represents a fundamental shift in how electronics are manufactured. Additionally, the growth in emerging technologies like HDI PCBs demonstrates the market’s evolution toward more sophisticated solutions.

Top 7 Benefits of Custom PCB Assembly for Your Business

Custom PCB assembly offers numerous advantages that standard solutions simply cannot match. Here are the most significant benefits:

1. Tailored Design for Optimal Performance

Every custom PCB assembly is designed specifically for your application. Consequently, you get maximum performance and efficiency from your electronic devices.

2. Enhanced Product Reliability

Custom assemblies undergo rigorous testing and quality control. Therefore, they typically offer superior reliability compared to standard alternatives.

3. Cost Efficiency in Medium Volumes

While initial costs may be higher, custom solutions often prove more cost-effective for medium production runs. Furthermore, they eliminate the need for expensive modifications to standard boards.

4. Faster Time-to-Market

Custom PCBA allows rapid prototyping and design iterations. As a result, you can bring products to market faster than competitors using standard solutions.

5. Intellectual Property Protection

Custom designs help protect your innovative ideas and technology. Additionally, they make it harder for competitors to reverse-engineer your products.

6. Flexibility for Future Modifications

Custom assemblies can be easily modified or upgraded. This flexibility is especially valuable for products with evolving requirements.

7. Specialized Application Support

Custom solutions excel in demanding environments like automotive, medical, or aerospace applications where standard boards may not meet requirements.

Essential Custom PCB Assembly Techniques You Should Know

Understanding the main assembly techniques is crucial for successful custom PCB projects. Each method has specific advantages and applications.

Surface Mount Technology (SMT)

SMT is the most common technique in modern custom PCB assembly. Furthermore, it offers several key advantages:

- High Component Density: Allows more components in smaller spaces

- Automated Assembly: Enables fast, precise component placement

- Cost Effectiveness: Reduces manufacturing costs for high volumes

- Superior Performance: Minimizes signal interference and improves speed

Through-Hole Technology

Through-hole assembly remains important for certain applications. Additionally, it provides unique benefits:

- Mechanical Strength: Creates stronger physical connections

- Heat Dissipation: Better thermal management for power components

- Repair Capability: Easier to service and modify

- Connector Reliability: Ideal for connectors and large components

Hybrid Assembly Methods

Many custom PCB projects use hybrid approaches combining SMT and through-hole techniques. This strategy optimizes both performance and reliability while meeting specific design requirements.

For more detailed information on PCB assembly techniques, visit the IPC Association website for industry standards and best practices.

The Custom PCB Assembly Process: Step-by-Step Breakdown

Understanding the custom PCBA process helps you plan better and set realistic expectations. Here’s how the process typically works:

Step 1: Design File Submission and Review (1-2 Days)

First, you submit your design files including Gerber files, BOM, and assembly drawings. Then, engineers review everything for manufacturability and potential issues.

Step 2: Component Sourcing and Procurement (3-7 Days)

Next, procurement specialists source all required components. This step involves verifying availability, pricing, and quality standards.

Step 3: PCB Fabrication (5-10 Days)

Meanwhile, the bare PCBs are manufactured according to your specifications. This includes drilling, plating, and surface finishing processes.

Step 4: Assembly Setup and Programming (1-2 Days)

Subsequently, technicians set up assembly equipment and program pick-and-place machines for your specific design.

Step 5: Component Assembly (1-3 Days)

Then, components are placed and soldered using appropriate techniques. This step requires careful attention to detail and quality control.

Step 6: Testing and Quality Control (1-2 Days)

After assembly, each board undergoes comprehensive testing including electrical, functional, and visual inspections.

Step 7: Final Packaging and Shipping (1-2 Days)

Finally, approved boards are packaged according to your requirements and shipped to your location.

Cost Factors in Custom PCB Assembly (And How to Save Money)

Understanding cost factors helps you budget effectively and identify savings opportunities. Here’s what influences custom PCBA pricing:

| Cost Factor | Impact Level | Typical Range | Money-Saving Tips |

|---|---|---|---|

| PCB Complexity | High | $10-$200 per board | Optimize layer count and via usage |

| Component Count | High | $0.10-$50 per component | Consolidate functions, use standard parts |

| Assembly Method | Medium | $0.05-$2 per component | Prefer SMT over through-hole when possible |

| Order Volume | High | Volume discounts up to 60% | Plan larger batches when feasible |

| Testing Requirements | Medium | $5-$50 per board | Define essential tests only |

Proven Money-Saving Strategies

- Design for Manufacturability: Simplify layouts and use standard component sizes

- Component Selection: Choose readily available parts over exotic components

- Volume Planning: Consolidate orders to achieve better pricing tiers

- Assembly Optimization: Minimize mixed technologies and complex routing

- Testing Strategy: Focus on critical tests rather than comprehensive coverage

How to Choose the Right Custom PCB Assembly Partner

Selecting the right assembly partner is crucial for project success. Here’s your comprehensive checklist:

Essential Capabilities to Look For

- Advanced Equipment: State-of-the-art SMT lines and testing equipment

- Quality Certifications: ISO 9001, ISO 13485, IATF 16949, and IPC standards

- Component Sourcing: Established supplier networks and procurement expertise

- Technical Support: Experienced engineers for design optimization

- Scalability: Ability to handle both prototypes and production volumes

Red Flags to Avoid

- Lack of relevant industry certifications

- No component sourcing capabilities

- Limited testing and quality control processes

- Poor communication or response times

- No experience with your specific industry requirements

Questions to Ask Potential Partners

- What certifications do you hold for my industry?

- How do you handle component sourcing and supply chain management?

- What testing capabilities do you offer?

- Can you provide references from similar projects?

- What’s your typical turnaround time for my volume requirements?

For additional guidance on selecting assembly partners, check out the Surface Mount Technology Association for industry insights and best practices.

Future Trends in Custom PCB Assembly (2025 and Beyond)

The custom PCB assembly industry is evolving rapidly. Understanding these trends helps you stay ahead of the competition and prepare for future opportunities.

1. AI-Driven Automation and Optimization

Artificial intelligence is revolutionizing custom PCB assembly. Furthermore, AI systems now optimize component placement, predict defects, and improve quality control processes.

2. Advanced Miniaturization Technologies

Component sizes continue shrinking while functionality increases. Additionally, new packaging technologies enable even greater miniaturization in custom designs.

3. Sustainable Manufacturing Practices

Environmental concerns are driving adoption of lead-free soldering, recyclable materials, and energy-efficient manufacturing processes.

4. Smart Factory Integration

Industry 4.0 technologies are creating smart factories with real-time monitoring, predictive maintenance, and automated quality control.

5. 5G and IoT Applications

The growth of 5G networks and IoT devices is creating new opportunities for specialized custom PCBA solutions.

6. Flexible and Rigid-Flex PCBs

Demand for flexible and rigid-flex PCBs is increasing, especially in wearable devices and compact electronics.

Stay updated on the latest trends by following industry publications like Circuits Assembly Magazine and Electronic Design.

Real Success Stories: Custom PCB Assembly Case Studies

Here are real examples of successful custom PCB assembly projects that demonstrate the value of specialized solutions:

Case Study 1: Automotive Driver Assistance System

Challenge: A leading automotive manufacturer needed custom PCBs for their advanced driver assistance system that could withstand extreme temperatures and vibrations.

Solution: Mustar developed a custom 8-layer PCB using high-TG materials with specialized component placement for thermal management. The design included automotive-grade components and conformal coating for environmental protection.

Results: The custom solution passed all automotive testing requirements and reduced system size by 40% compared to standard alternatives. Additionally, the project achieved IATF 16949 compliance and 99.8% reliability rates.

Case Study 2: Medical Device Control Board

Challenge: A medical device company required custom PCBA for a portable respiratory monitoring system with strict FDA requirements and biocompatibility standards.

Solution: The team created a custom 6-layer flexible-rigid PCB design with medical-grade components and specialized testing protocols. The solution included wireless connectivity and ultra-low power consumption features.

Results: The custom assembly achieved ISO 13485 certification and enabled 72-hour continuous operation on a single charge. Furthermore, the device received FDA approval and is now used in hospitals worldwide.

Case Study 3: Industrial IoT Gateway

Challenge: An industrial automation company needed custom PCBs for their IoT gateway that could operate in harsh factory environments while supporting multiple communication protocols.

Solution: Engineers designed a custom 10-layer PCB with specialized shielding and industrial-grade components. The solution included redundant power supplies and advanced EMI protection.

Results: The custom gateway achieved 99.9% uptime in industrial environments and supported 500+ connected devices simultaneously. Moreover, it reduced installation costs by 30% through integrated functionality.

Frequently Asked Questions About Custom PCB Assembly

Q1: What is custom PCB assembly?

Custom PCB assembly is the process of manufacturing printed circuit boards tailored to specific design requirements. This involves placing and soldering electronic components on PCBs using techniques like SMT and through-hole technology. Unlike standard PCBs, custom assemblies are designed for unique applications and specifications.

Q2: How much does custom PCB assembly cost?

Costs typically range from $3-$4 per board for simple designs to hundreds of dollars for complex, high-density PCBs. The final price depends on factors like PCB complexity, component count, assembly methods, and order volume. Larger quantities generally reduce per-unit costs significantly.

Q3: What are the main benefits of custom PCB assembly?

Key benefits include optimized design for specific applications, improved performance and reliability, potential cost savings in medium volumes, faster prototyping, and flexibility for design changes. Custom assembly also provides better quality control through focused testing and validation.

Q4: How long does custom PCB assembly take?

Typical turnaround time is 12-25 business days for standard projects. This includes design review, component sourcing, PCB fabrication, assembly, testing, and shipping. Rush orders may be available for urgent projects, though they typically cost more.

Q5: What files do I need to provide for custom PCB assembly?

You’ll need Gerber files, drill files, Bill of Materials (BOM), assembly drawings, and pick-and-place files. Additionally, providing component specifications, testing requirements, and quality standards helps ensure successful assembly.

Q6: Can you help with component sourcing for custom projects?

Yes, professional assembly partners typically offer component sourcing services. They maintain relationships with suppliers worldwide and can often find alternatives that reduce costs while maintaining quality and functionality.

Q7: What quality standards should I expect?

Look for partners with certifications like ISO 9001 (general quality), ISO 13485 (medical), IATF 16949 (automotive), and IPC standards. These certifications ensure consistent quality processes and industry compliance.

Q8: What’s the minimum order quantity for custom PCBA?

Many manufacturers offer prototype services starting from just a few pieces. However, cost-effectiveness typically improves with larger quantities. Minimum orders vary by manufacturer and complexity, but many start at 10-50 pieces.

Q9: How do I ensure my custom PCB design is manufacturable?

Work with experienced engineers who can review your design for manufacturability. They’ll check component availability, assembly feasibility, and testing requirements. Design for Manufacturing (DFM) reviews are standard practice for quality assembly partners.

Q10: What testing is included with custom PCB assembly?

Standard testing typically includes visual inspection, electrical testing, and functional verification. Advanced testing may include In-Circuit Testing (ICT), Functional Circuit Testing (FCT), and environmental testing. Discuss specific testing requirements with your assembly partner.

For more detailed technical information, visit Electronics Cooling for thermal management insights and PCB007 for the latest industry news and technical articles.

Ready to Start Your Custom PCBA Project?

Don’t let standard solutions limit your innovation. Mustar’s 25+ years of experience, advanced manufacturing capabilities, and commitment to quality make us the ideal partner for your custom PCBA needs.

Why Choose Mustar for Your Custom PCB Assembly?

- ✅ Over 600 skilled professionals with 25+ years of experience

- ✅ 20 SMT lines and 5 DIP lines for scalable production

- ✅ ISO 9001, ISO 13485, IATF 16949 certified quality systems

- ✅ 200+ global suppliers for reliable component sourcing

- ✅ Advanced testing including 3D X-Ray, AOI, and ICT

- ✅ 4-8 hour PCB sample production for rapid prototyping

Get your custom PCBA quote today and join over 100 successful companies who trust Mustar for their electronics manufacturing needs.

Contact us today: Our expert team is ready to discuss your custom PCBA requirements and provide a detailed quote within 24 hours.

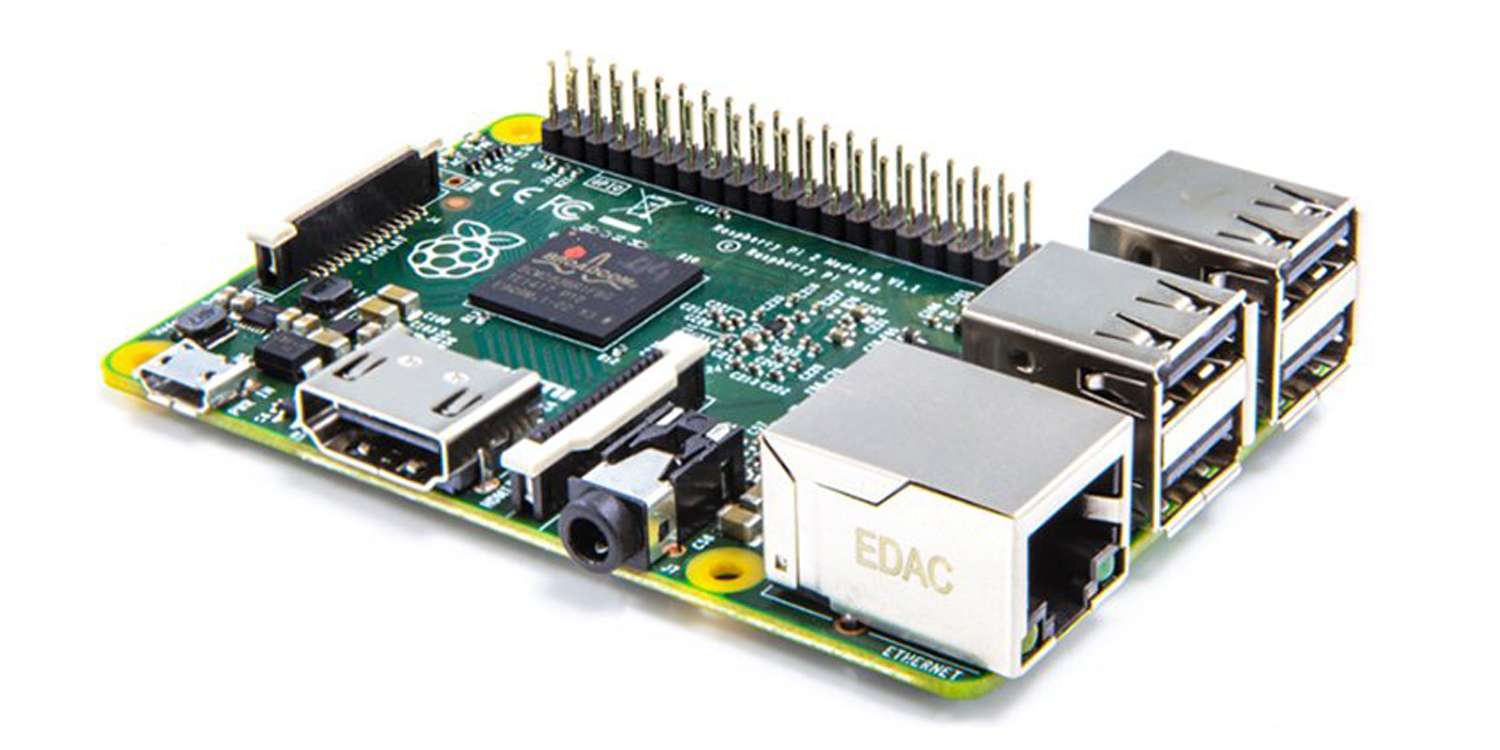

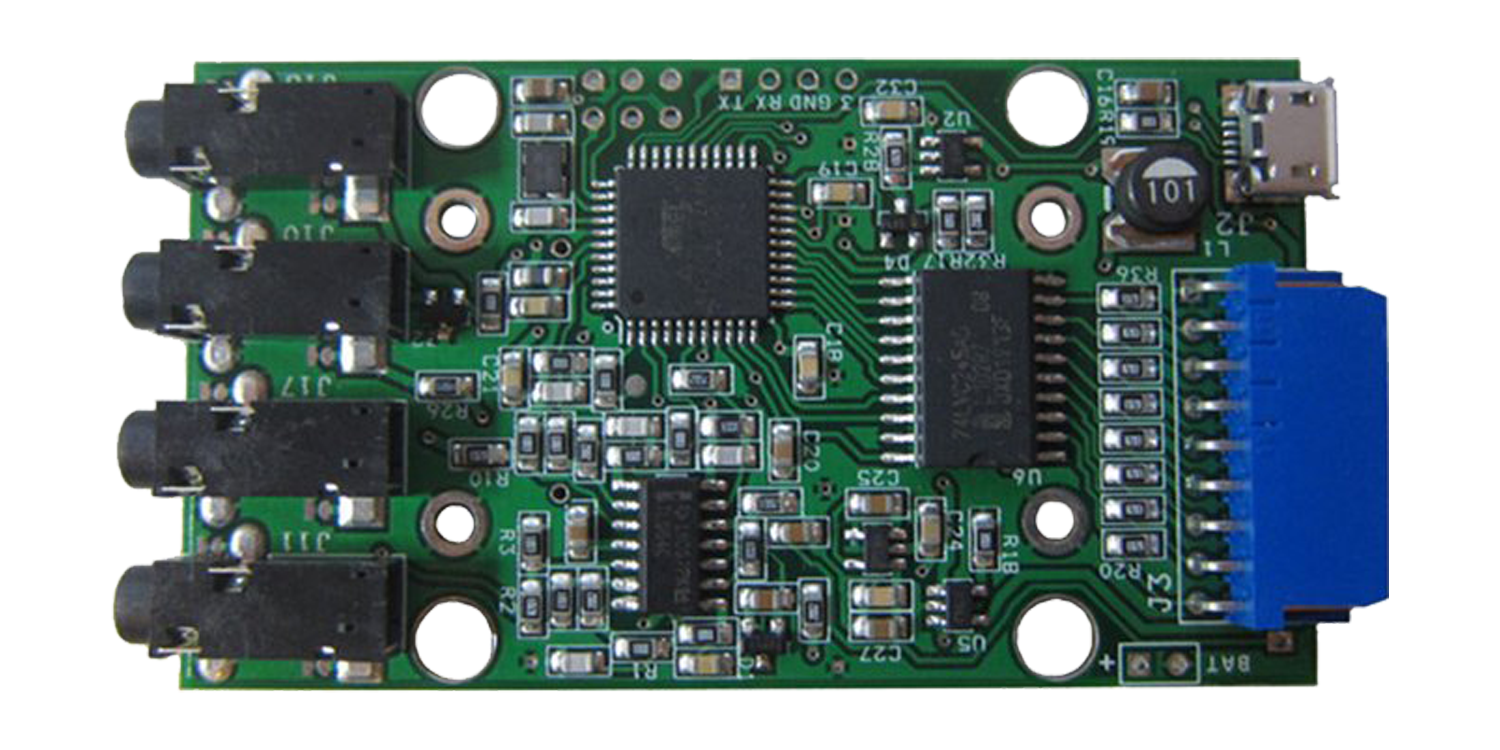

Mustar projects: