Contents

- What is Custom PCBA?

- Key Materials and Components in Custom PCBA

- Types of Custom PCBA Solutions

- The Complete Custom PCBA Manufacturing Process

- Industries That Depend on Custom PCBA

- Essential Quality Standards and Certifications

- Benefits of Custom PCBA for Your Business

- How to Choose the Right Custom PCBA Manufacturer

What is Custom PCBA? (Complete Definition Guide)

Custom PCBA stands for Custom Printed Circuit Board Assembly, and it represents a complete electronic manufacturing solution. Furthermore, this process goes far beyond creating simple circuit boards. Instead, custom PCBA involves designing, manufacturing, and assembling fully functional electronic circuits tailored to your specific needs.

The key difference between custom PCBA and standard PCB manufacturing lies in the level of customization. While standard PCBs offer generic solutions, custom PCBA provides:

- Tailored Design: Components and layout optimized for your specific application

- Complete Assembly: All components soldered and tested, ready for integration

- Performance Optimization: Circuit design matched to your exact performance requirements

- Cost Efficiency: Elimination of unnecessary features and components

Businesses choose custom PCBA solutions because they need electronic circuits that perfectly match their product requirements. Moreover, custom solutions often provide better performance, lower costs, and faster time-to-market compared to adapting generic alternatives.

According to IPC (Association Connecting Electronics Industries), the demand for custom PCBA continues growing as IoT devices, automotive electronics, and medical equipment require increasingly specialized solutions.

Key Materials and Components in Custom PCBA

Understanding the materials used in custom PCBA helps you make better decisions for your project. Therefore, let’s explore the essential components that make up these sophisticated electronic assemblies.

Substrate Materials

FR4 (Fire Retardant 4) remains the industry standard for most applications. However, specialized projects may require different materials:

- Rogers Materials: High-frequency applications requiring low signal loss

- Aluminum Substrates: LED applications needing excellent heat dissipation

- Flexible Materials: Polyimide for bendable and foldable designs

- High-TG Materials: Applications requiring high-temperature resistance

- Teflon Substrates: Extreme high-frequency and low-loss applications

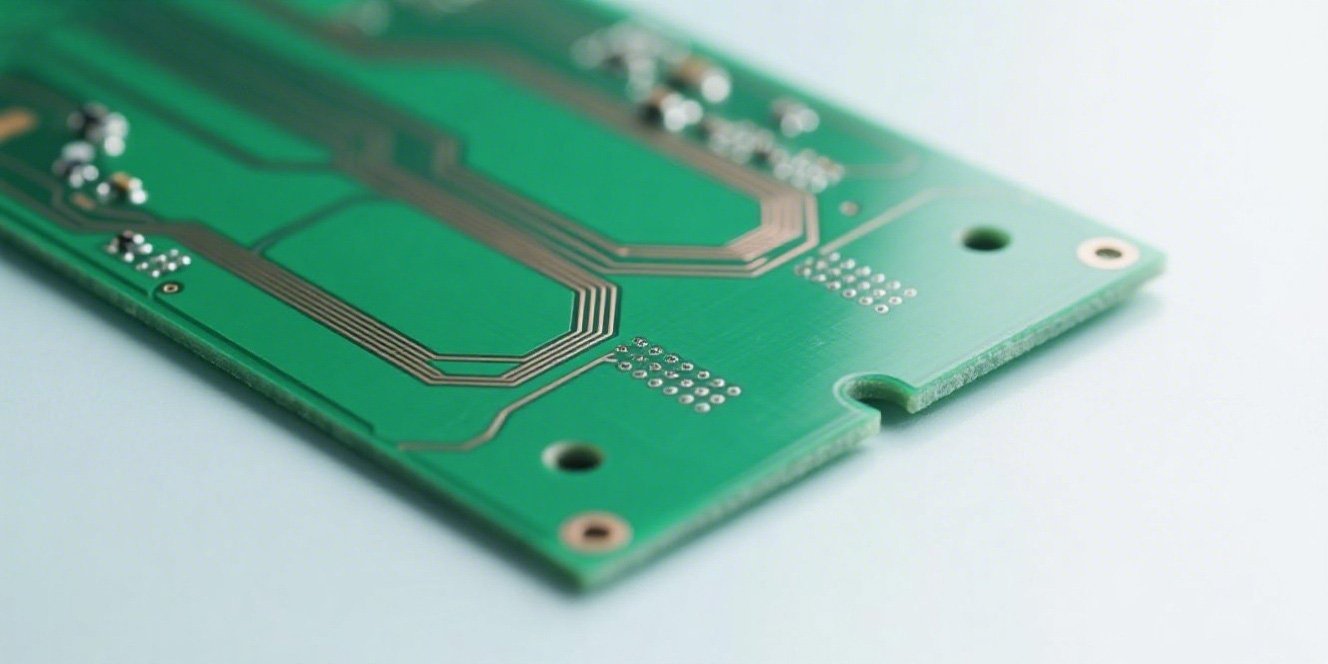

Copper Layer Specifications

Copper layers form the electrical pathways in your custom PCBA. Additionally, the standard weight specification is 1 ounce per square foot, though some applications require heavier copper for high-current handling.

Protection and Identification Layers

Two crucial protective elements complete the material stack-up:

- Solder Mask: Protects copper traces and prevents short circuits

- Silkscreen: Provides component identification and assembly guidance

For more detailed information about PCB materials, visit PCB Design & Manufacturing Resources which provides comprehensive material specifications and selection guides.

Types of Custom PCBA Solutions

Different applications require different types of custom PCBA solutions. Consequently, understanding these variations helps you choose the right approach for your project.

Rigid PCBAs

Standard applications requiring solid, inflexible boards. Available in 1-64 layer configurations for simple to complex designs.

Flexible PCBAs

Bendable applications like wearable devices, cameras, and space-constrained electronics where flexibility is essential.

Rigid-Flex PCBAs

Combines rigid and flexible sections, offering the best of both worlds for complex 3D electronic designs.

Rigid PCBAs: The Industry Standard

Rigid custom PCBAs serve most electronic applications. These boards range from simple single-layer designs to highly complex 64-layer configurations. Moreover, rigid PCBAs offer excellent mechanical stability and cost-effectiveness for standard applications.

Flexible PCBAs: Bending the Rules

Flexible custom PCBAs enable innovative product designs. Furthermore, these solutions excel in applications requiring:

- Space-constrained installations

- Moving or rotating connections

- Weight reduction requirements

- 3D electronic packaging

Rigid-Flex PCBAs: Best of Both Worlds

Rigid-flex custom PCBAs combine the stability of rigid boards with the flexibility of flex circuits. Therefore, they’re perfect for complex electronic systems requiring both solid mounting points and flexible interconnections.

Industry-Specific Requirements

Different industries have unique custom PCBA requirements:

- Automotive: High-temperature resistance and vibration tolerance

- Medical: Biocompatibility and sterilization compatibility

- Aerospace: Extreme temperature and radiation resistance

- Industrial: EMI shielding and harsh environment protection

The Complete Custom PCBA Manufacturing Process

The custom PCBA manufacturing process involves multiple carefully coordinated stages. Additionally, understanding this process helps you plan your project timeline and ensure quality results.

Design Phase: From Concept to Layout

The design phase transforms your requirements into a manufacturable custom PCBA design. This critical stage includes:

- Schematic Design: Converting functional requirements into electrical circuits

- Component Selection: Choosing optimal components for performance and cost

- Layout Design: Optimizing component placement and routing

- Design Rule Check: Ensuring manufacturability and reliability

Fabrication Stage: Creating the PCB Foundation

PCB fabrication creates the foundation for your custom PCBA. Moreover, this stage involves precise control of multiple manufacturing steps to achieve the required specifications.

Assembly Process: Bringing Components Together

The assembly process transforms bare PCBs into functional custom PCBAs through several technologies:

- SMT (Surface Mount Technology): Placing and soldering surface-mount components

- DIP (Dual In-line Package): Installing through-hole components

- Mixed Technology: Combining SMT and DIP for optimal design flexibility

- Ultra-fine Pitch Assembly: 01005 components and advanced BGA packages

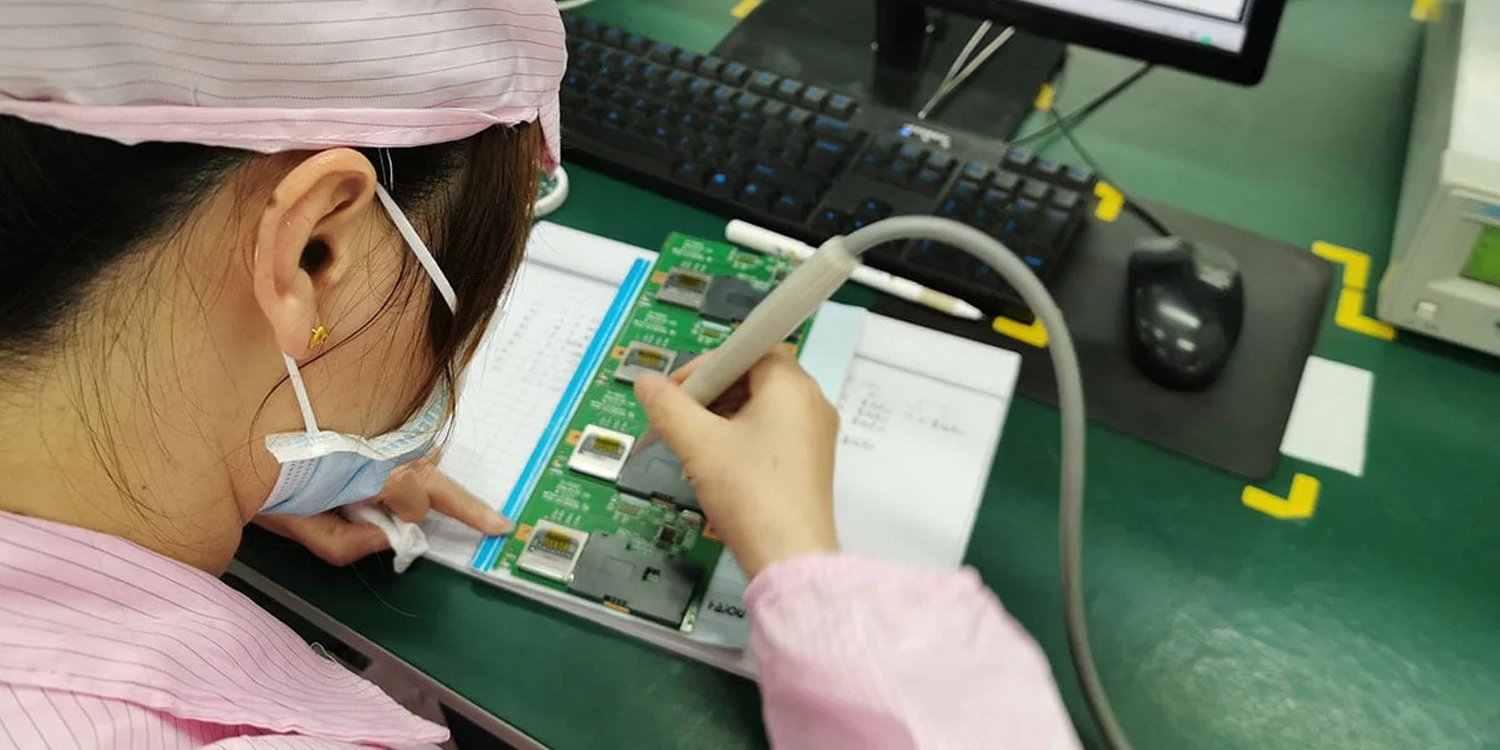

Testing Phase: Ensuring Quality and Reliability

Comprehensive testing ensures your custom PCBA meets all requirements:

- ICT (In-Circuit Testing): Verifying component values and connections

- FCT (Functional Circuit Testing): Testing actual circuit performance

- AOI (Automated Optical Inspection): Detecting assembly defects

- 3D X-Ray Inspection: Examining hidden solder joints

Timeline Expectations

Understanding realistic timelines helps plan your project effectively:

- Prototypes: 4-8 hours for PCB samples, 3-7 days for complete PCBA

- Small Batch: 1-2 weeks depending on component availability

- Mass Production: 2-4 weeks for standard complexity designs

For additional insights into PCB manufacturing processes, reference Circuit Insight, which provides detailed manufacturing guides and industry best practices.

Industries That Depend on Custom PCBA

Custom PCBA solutions power innovation across multiple industries. Furthermore, each sector has unique requirements that make custom solutions essential rather than optional.

🚗 Automotive

500+ PCBA types, IATF16949 certified quality standards

🏥 Medical

ISO13485 compliance for life-critical applications

⚡ New Energy

Solar inverters and battery management systems

🤖 Industrial AI

Robotics and automation control systems

Automotive: Driving Electronic Innovation

The automotive industry relies heavily on custom PCBA for advanced vehicle systems. Additionally, modern vehicles contain hundreds of electronic control units, each requiring specialized custom PCBAs.

Key automotive custom PCBA applications include:

- Motor Driver PCBAs: Controlling electric vehicle propulsion systems

- Car Audio Systems: Advanced infotainment and connectivity features

- Driver Assistance Systems: Safety-critical ADAS applications

- Battery Management: EV battery monitoring and control systems

Automotive custom PCBA requires IATF16949 certification, ensuring the highest quality standards for safety-critical applications.

Medical Devices: Life-Critical Reliability

Medical custom PCBA applications demand exceptional reliability and regulatory compliance. Moreover, these devices often operate in challenging environments while maintaining precise performance.

Common medical custom PCBA applications:

- Respiratory Equipment: Ventilator control boards with life-critical functions

- Diagnostic Equipment: B-ultrasound and imaging system control boards

- Patient Monitoring: Smart blood pressure and vital sign monitors

- Surgical Instruments: Precision control systems for surgical equipment

Medical custom PCBA requires ISO13485 certification, ensuring compliance with medical device quality management standards.

New Energy: Powering the Future

The new energy sector drives significant demand for specialized custom PCBA solutions. Furthermore, these applications require robust designs capable of handling high power and harsh environmental conditions.

New energy custom PCBA applications include:

- Solar Inverters: Converting DC solar power to AC grid power

- Battery Management Systems: Monitoring and protecting energy storage systems

- EV Chargers: Fast-charging infrastructure control systems

- Grid Management: Smart grid monitoring and control equipment

Industrial Control & AI: Automation Revolution

Industrial automation increasingly relies on sophisticated custom PCBA solutions. Additionally, AI integration requires advanced processing capabilities and specialized sensor interfaces.

Industrial custom PCBA applications encompass:

- Industrial Mainboards: Central processing units for factory automation

- Robotics Control: Motion control and sensor integration systems

- Smart Manufacturing: IoT-enabled production monitoring equipment

- Process Control: Chemical and manufacturing process automation

For industry-specific design guidelines, consult Design News, which provides comprehensive coverage of engineering applications across industries.

Essential Quality Standards and Certifications

Quality standards and certifications ensure your custom PCBA meets industry requirements and regulatory compliance. Moreover, these standards protect both manufacturers and end-users by establishing consistent quality benchmarks.

- ISO 9001: Quality management system foundation

- ISO 13485: Medical device quality management

- IATF 16949: Automotive quality management system

- RoHS: Restriction of hazardous substances compliance

- CE Marking: European conformity standards

- UL Certification: Safety testing and certification

ISO Certifications: Quality Foundation

ISO 9001 provides the foundation for quality management in custom PCBA manufacturing. Furthermore, this certification ensures consistent processes, continuous improvement, and customer satisfaction focus.

ISO 13485 specifically addresses medical device manufacturing requirements. Additionally, this standard ensures custom PCBA for medical applications meets the strict quality and traceability requirements necessary for patient safety.

ISO 14001 demonstrates environmental management commitment. Moreover, this certification shows responsible manufacturing practices and environmental impact reduction.

Safety Standards: Protecting End Users

RoHS (Restriction of Hazardous Substances) compliance ensures custom PCBA doesn’t contain harmful materials like lead, mercury, and cadmium. Furthermore, RoHS compliance is mandatory for electronics sold in Europe and increasingly required globally.

CE Marking indicates conformity with European safety, health, and environmental requirements. Additionally, CE marking is required for custom PCBA used in products sold within the European Economic Area.

UL Certification provides independent safety testing and verification. Moreover, UL certification gives confidence that custom PCBA meets stringent safety requirements for various applications.

Industry-Specific Standards

IATF 16949 represents the automotive industry’s highest quality standard. Furthermore, this certification ensures custom PCBA for automotive applications meets the demanding reliability and safety requirements of modern vehicles.

Why These Certifications Matter

Proper certifications provide multiple benefits for your custom PCBA project:

- Regulatory Compliance: Meeting legal requirements for your target markets

- Quality Assurance: Consistent manufacturing processes and outcomes

- Risk Mitigation: Reduced liability and product failure risks

- Market Access: Ability to sell in regulated markets worldwide

For comprehensive certification information, visit TÜV SÜD, which provides detailed certification services and requirements for electronic products.

Benefits of Custom PCBA for Your Business

Custom PCBA solutions offer significant advantages over generic alternatives. Moreover, these benefits often justify the investment through improved performance, reduced costs, and competitive advantages.

Performance Optimization: Tailored for Excellence

Custom PCBA enables precise performance optimization for your specific requirements. Furthermore, this tailored approach often delivers superior results compared to adapting generic solutions.

Performance benefits include:

- Optimized Circuit Design: Electrical characteristics matched to your exact needs

- Reduced Signal Interference: Layout optimization for minimal EMI/EMC issues

- Thermal Management: Heat dissipation designed for your operating conditions

- Size Optimization: Minimal footprint while maintaining functionality

Cost Efficiency: Smart Investment Strategy

While custom PCBA may have higher initial costs, the long-term savings often exceed the investment. Additionally, cost optimization opportunities include:

- BOM Optimization: Eliminating unnecessary components and features

- Volume Pricing: Better component costs through consolidated purchasing

- Reduced Assembly Costs: Optimized designs reduce manufacturing complexity

- Lower Field Failure Rates: Reduced warranty and support costs

Scalability: From Prototype to Production

Custom PCBA solutions provide smooth scaling from initial prototypes to mass production. Moreover, this scalability ensures consistent quality and performance across all production volumes.

Scalability advantages encompass:

- Design for Manufacturing: Optimized for efficient production scaling

- Supply Chain Integration: Established component sourcing for volume production

- Quality Consistency: Standardized processes ensure uniform results

- Time-to-Market: Faster product launch through streamlined development

Competitive Advantage: Standing Out in the Market

Custom PCBA enables unique product features that differentiate your offerings. Furthermore, this competitive advantage often translates into market leadership and premium pricing opportunities.

How to Choose the Right Custom PCBA Manufacturer

Selecting the right custom PCBA manufacturer significantly impacts your project’s success. Therefore, careful evaluation of potential partners ensures optimal results and long-term success.

Technical Capabilities

Evaluate layer count, component types, and advanced technologies offered by potential manufacturers.

Quality Certifications

Verify relevant industry certifications and quality management systems.

Experience & Support

Assess industry experience, engineering support, and customer service capabilities.

Production Capacity

Ensure adequate capacity for your current and future volume requirements.

Essential Technical Capabilities

Your chosen manufacturer must possess the technical capabilities required for your custom PCBA project. Additionally, advanced capabilities often indicate superior manufacturing expertise.

Key technical capabilities to evaluate:

- Layer Count Range: Ability to produce from simple single-layer to complex 64-layer designs

- Component Capabilities: Ultra-fine pitch components like 01005, BGA, and QFN packages

- Advanced Technologies: Blind/buried vias, embedded components, impedance control

- Material Options: FR4, Rogers, aluminum, flexible, and specialized substrates

Critical Questions to Ask Potential Manufacturers

Asking the right questions helps identify the best custom PCBA manufacturing partner:

- Experience: “How many years have you been manufacturing custom PCBA?”

- Certifications: “What quality certifications do you maintain?”

- Capacity: “What are your current production capacities and lead times?”

- Testing: “What testing and quality control processes do you use?”

- Support: “What engineering and technical support do you provide?”

Red Flags to Avoid

Certain warning signs indicate potential problems with custom PCBA manufacturers:

- Lack of Certifications: Missing relevant industry quality certifications

- Poor Communication: Delayed responses or unclear technical discussions

- Limited Capabilities: Inability to handle your technical requirements

- No References: Unwillingness to provide customer references or case studies

- Unrealistic Promises: Extremely low prices or impossible delivery timelines

Evaluation Checklist

Use this checklist to systematically evaluate potential custom PCBA manufacturers:

- ✓ Technical capabilities match project requirements

- ✓ Relevant quality certifications (ISO, IATF, RoHS, etc.)

- ✓ Adequate production capacity for your volumes

🚀 Ready to Power Your New Energy Innovation?

Mustar combines 25+ years of PCBA expertise with specialized knowledge in new energy applications. Our certified manufacturing processes, advanced testing capabilities, and global supply chain ensure your project success.

Why Choose Mustar for Your New Energy PCBA?

- ✅ IATF16949 & ISO13485 certified quality systems

- ✅ Dedicated new energy production lines

- ✅ Advanced testing with 3D X-Ray and ICT/FCT

- ✅ 200+ global suppliers ensuring component availability

- ✅ Fast prototyping with 4-8 hour PCB samples

Contact Mustar today and discover how our new energy PCBA expertise can accelerate your project from concept to market success!

Mustar projects: