In PCB Assembly(PCBA),the Bill Of Materials (BOM), can account for more than 60% of the total project cost . Many businesses overspend unknowingly due to:

-

Selection of redundant components (e.g. using high precision parts in circuits that are not critical)

-

Supply chains that are fragmented and inconsistencies in sourcing

-

Design that ignores manufacturability and results in hidden production costs

According IPC research BOM optimization could yield 15%-30% savings in cost without sacrificing reliability.

Is your BOM still hiding cost-saving potential?

What is the best way to strike a balance with lower costs and better product quality?

Mustar’s experience with 300+ PCBA project has led to the development of 7 strategies that can be used to optimize your BOM, and lower total costs.

1. Standardize Component Selection

Strategy : Create a Preferred Parts List to eliminate proprietary or rare components.

Mustar Insight:

We helped a customer replace five exclusive components with standard options, lowering the BOM cost by 22 % without affecting performance.

2. Reliable local substitution

Strategy : Compare parameters and test reliability of domestic components.

Mustar Capability:

Our in-house laboratory includes high/low temperature cycling and 1,000-hour aging tests to validate local options before mass production.

3. Use VMI to consolidate supply chain & use VMI

Strategy : Implement Vendor Managed Inventory to reduce procurement and stock costs.

Mustar Advantage:

We have strategic agreements in place with suppliers of the highest quality, such as TI and Murata. This allows our customers to enjoy annual discounts on bulk purchases.

Learn how Mustar sources components

4. Optimized Design for High Integrity

Strategy Use integrated modules or SoCs to reduce the number of PCB layers and peripheral circuits.

Mustar Support:

Our DFM service helped our client redesign their layout by removing redundant components, and reducing cost by 37%.

5. Improve Panelization & Material Usage

Strategy Optimize the panel layout to maximize board usage and reduce waste.

Mustar Manufacturing strength

“We support 0.2mm spacing in panel designs. “Our SMT line increased board usage to 92% in one instance.”

6. Use Excess Inventory Wisely

Strategy : Match BOM with existing stock or alternative parts pools to utilize surplus inventory

Mustar Innovation:

Clients can search in real-time for compatible parts using our Obsolete Material Platform.

7. Real-time Cost Monitoring of BOM

Strategy : Integrate ERP to track changes in prices and receive alerts when they rise.

Mustar Tool:

We provide real-time dashboards for BOM costs and price fluctuations to keep clients ahead of the market.

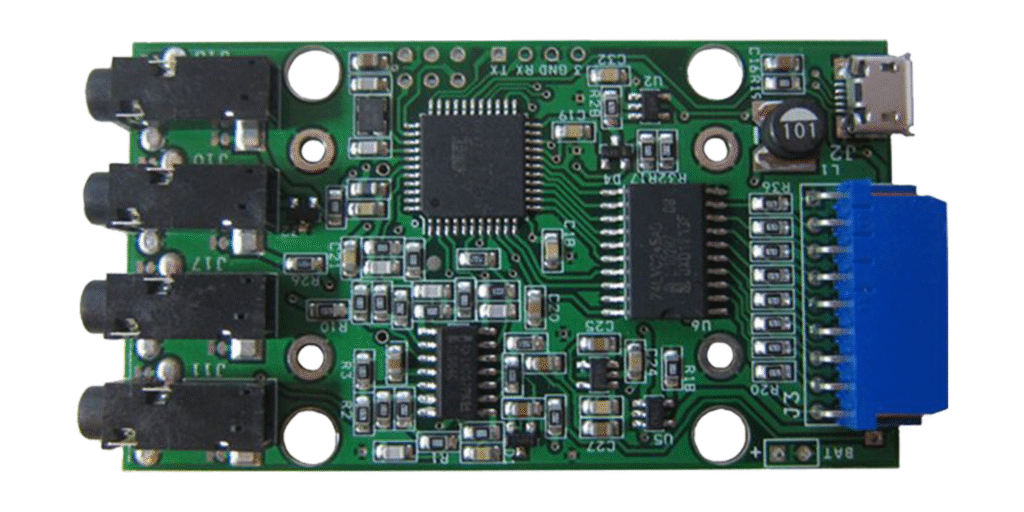

Mustar Case study: Cost of BOM reduced by 28%

Project : Industrial Controller PCBA

Issue : Over-engineered Design, Imported MCUs with Long Lead Time, High Cost per Unit

Mustar’s Solution:

-

Replaced MCU by a local equivalent that has been validated

-

Combining power modules with SoC

-

Reduced PCB to two layers from four layers (validated by SI simulation).

Result:

-

Reduced cost per unit from $18.50 down to $13.30

-

Improved production yield to 99.2%

Client Feedback:

The engineering team at Mustar found cost-savings opportunities that we had not even considered.

Why BOM optimization is not just about cost

To reduce BOM costs, you don’t have to cut corners. Instead, it’s important to leverage engineering knowledge, supplier network and data in real time.

Why choose Mustar for PCB Assembly

Overview of the Company

Mustar, a Shenzhen based turnkey Assembly PCB manufacturer has over 25 years’ experience and completed more than 5,000 electronic projects.

Our Strengths

-

PCB Manufacturing, component sourcing and assembly, as well as testing, are all offered by One-Stop services.

-

Proven Results: Over 300 BOM optimization cases in medical, automotive and industrial electronics

-

Certifications: ISO 9001, IATF 16949, ISO 13485, RoHS, UL, IPC Class 2

-

Infrastructure: 16 SMT Lines, 600+ Staff, 12,000m2 Factory

-

Speed: 3-7 days prototyping, and 8-hour Express PCB fabrication

-

Flexible: no minimum order quantity, free functional tests, 24/7 engineering support

Are you ready to reduce BOM costs?

BOM optimization is not just about price negotiation. It’s a strategic mix of data, technology and supply chain.

Contact Mustar today to get your free BOM cost diagnosis and customized optimization plan. Limited Offer: First 50 customers receive our BOM Cost Reduction Checklist (PDF) for free.

🚀 READY TO START ?

Experience the Mustar difference – from prototype to production, we’re your trusted partner in Chinese PCB assembly excellence.

Join over 1000+ satisfied customers who trust Mustar for their Chinese PCB assembly needs. Your success story starts with a single click.

Mustar projects: